Will Nylon Fray If You Cut It? How Do You Cut Nylon Webbing Without Fraying?

[^1] showing frayed edges](https://hxcuttingmachine.com/wp-content/uploads/2025/03/36-_-md_image_generation_for_webbing_cutting_machi-1-scaled.jpg)

Cut nylon webbing with scissors, and you’ll get fuzzy, frayed edges almost instantly. It looks unprofessional—and it weakens the strap over time.

Yes, nylon will fray when cut unless you seal the edges with heat. The best way to cut nylon webbing without fraying is to use a hot knife1 or a heat-integrated cutting machine2.

I’ve tested dozens of tools in my own factory. Some cut fast but leave frayed edges. Others seal perfectly—but are too slow for industrial use. Here’s what works and why.

Will Nylon Fray If You Cut It?

Most synthetic materials behave the same way when cut—especially nylon.

Yes, nylon webbing will fray if cut with a cold blade or scissors. Fraying weakens the structural integrity of the webbing and looks messy.

Nylon is made of tightly woven synthetic fibers. When you cut it cold, the fibers separate and unravel.

Why Fraying Happens in Nylon

- Synthetic fibers are smooth and slippery.

- The weave unravels once a strand breaks.

- The edges are not sealed like natural fabric.

If left untreated, frayed edges can:

- Compromise load-bearing capacity

- Get stuck in hardware like buckles

- Create safety hazards in medical or industrial applications

That’s why at Suzhou Haoxinhe Electrical Equipment Co., Ltd., we never recommend cold cutting nylon webbing unless a post-sealing process is added.

How Do You Cut Nylon Webbing Without Fraying?

Cutting clean lines on nylon doesn’t require luck—it requires heat.

To cut nylon webbing3 without fraying, use a hot knife, heat blade cutter, or a hot and cold cutting machine. These tools melt and seal the edges instantly.

Method 1: Use a Hot Knife

This is ideal for low to medium volume tasks.

How to Use:

- Plug in the hot knife and wait for it to reach temp.

- Align the webbing on a flat surface.

- Slice slowly, letting heat melt the edges as it cuts.

- Let it cool for 10–15 seconds before handling.

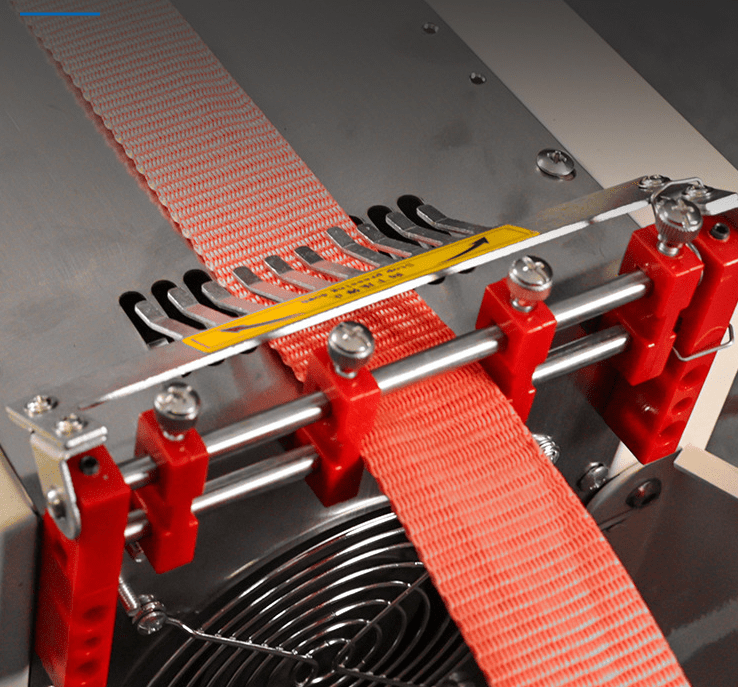

Method 2: Use a Heat-Integrated Cutting Machine

This is what we use in our factory for bulk orders.

At Suzhou Haoxinhe, we manufacture:

- Webbing tape cutting machine with heat blades

- Hot and cold cutting machines (switchable modes)

- Automatic punching cutting machines (with heat seal)

Method Comparison

| Method | Speed | Fray-Free | Recommended For |

|---|---|---|---|

| Scissors or utility knife | Fast | ❌ | Emergency use only |

| Hot knife | Medium | ✅ | Small production, DIY |

| Hot cutting machine | Very fast | ✅✅ | Industrial-scale production |

| Laser cutter | Medium | ✅ | Complex shapes, slower setup |

Our Production Line Experience

We’ve worked with clients across North America, Europe, and Southeast Asia needing clean cuts on:

- PVC edge banding

- Protective foam

- Bubble wrap

- Round/tubular webbing

Many buyers told us their previous Chinese suppliers used cold blades, resulting in frayed edges and client complaints. Once we upgraded them to our high-speed hot knife webbing cutters, their return rates dropped significantly.

Pro Tips for Fray-Free Cutting

Here’s what I always tell buyers sourcing from China or Vietnam:

- Ask your supplier if they use hot or cold blades.

- Request a photo or video of cut edge samples.

- Look for dark, sealed edges—that’s a good heat cut.

- If using manual tools, always use a flame or hot knife after.

At Suzhou Haoxinhe, our computer-controlled webbing tape cutting machines allow:

- Exact length control

- Sealed, smooth edges

- Programmable cutting modes for ribbon, film, foam, or straps

Conclusion

Yes, nylon will fray if cut with scissors or blades. Use a hot knife or automated heat cutter to get clean, sealed edges for durable and professional results.

Insights

Nylon webbing frays when cut with cold tools. The cleanest way to cut it is by using a hot knife or a cutting machine with integrated heat. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers webbing tape cutting machines and hot and cold cutting systems that melt-seal nylon edges instantly. Our machines are trusted by factories across Europe and North America for their speed, precision, and fray-free results—perfect for PVC edge banding, foam, and bubble wrap too.

Meta Description

Learn why nylon frays when cut and discover the best tools to cut nylon webbing3 without fraying. Suzhou Haoxinhe offers hot knife1 and heat cutting machines for clean, sealed cuts.

Discover how a hot knife can provide fray-free cuts on nylon webbing, enhancing your cutting efficiency and product quality. ↩ ↩

Find out how heat-integrated cutting machines can revolutionize your cutting process, ensuring clean edges and reducing waste. ↩

Explore this resource to learn effective techniques for cutting nylon webbing cleanly and professionally, ensuring durability and safety. ↩ ↩