Why Use a Roll-to-Roll Velcro Die Cutter in Large-Scale Manufacturing?

Manual cutting can’t keep up — and in large-scale manufacturing, even small inefficiencies add up fast.

A roll-to-roll Velcro die cutter1 automates the entire cutting process, delivering continuous, high-speed output with precision and minimal waste.

Let’s break down why this machine is the smart choice for factories producing Velcro dots, strips, or specialty shapes in volume.

What is a roll-to-roll Velcro die cutter1?

Most standard cutting machines require stop-and-start operations — feeding one piece at a time. That’s fine for small runs, not for full-scale production.

A roll-to-roll Velcro die cutter feeds material continuously from input to output, cutting Velcro in one seamless automated process.

How It Works

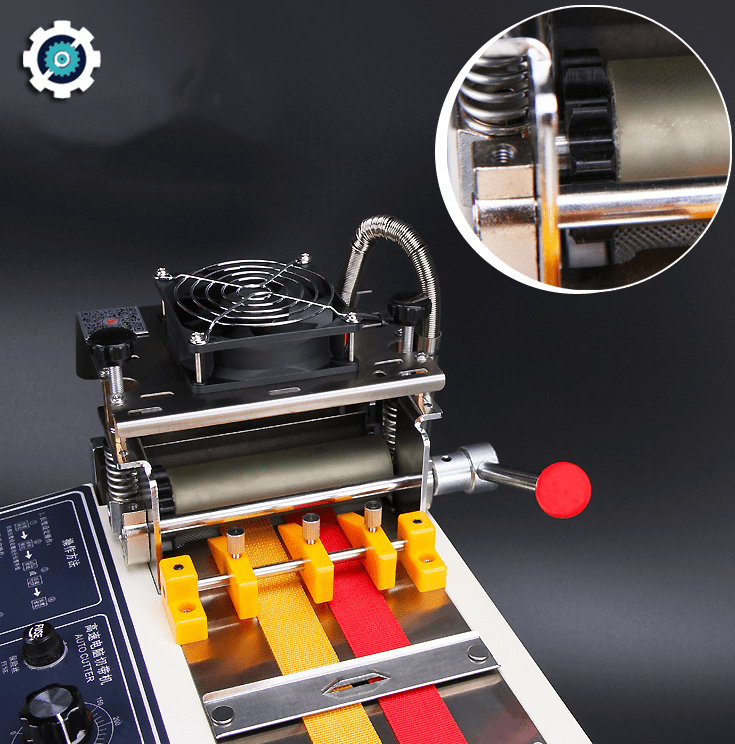

- Step 1: Velcro tape is loaded onto a roll feeder

- Step 2: The material passes through a rotary die

- Step 3: The die cuts dots or shapes at high speed

- Step 4: Cut pieces are collected or rewound automatically

- Step 5: Waste matrix is removed cleanly

This continuous motion is what allows you to produce 10,000+ dots per hour — with ±0.2mm precision and no operator fatigue.

Why is it ideal for high-volume Velcro production2?

Large factories can’t afford downtime, labor-heavy workflows, or uneven results — not when output needs to scale fast.

A roll-to-roll die cutter handles large volumes of Velcro tape without interruption, reducing labor costs, increasing output, and ensuring consistency.

Key Advantages

| Feature | Traditional Machine | Roll-to-Roll Die Cutter |

|---|---|---|

| Feed Type | Manual or semi-auto | Fully automatic |

| Output/hr | 500–1,000 pcs | 10,000+ pcs |

| Operator Load | High | Low |

| Downtime | Frequent | Minimal |

| Waste | Moderate | Low |

| Integration | Standalone | Inline compatible |

Perfect for:

- Uniform factories producing patches, name tags, and straps

- Medical gear suppliers needing clean, consistent closures

- Packaging companies using resealable components

- Textile plants with modular assembly lines

Suzhou Haoxinhe Electrical Equipment Co., Ltd. has delivered roll-to-roll systems across Europe, Southeast Asia, and North America — each one configured to exact client specs.

What customization and material support3 does it offer?

Not all Velcro is the same. Large-scale factories often use various grades, adhesives, widths, and backing options across product lines.

Our roll-to-roll Velcro die cutter1 supports multiple materials and die shapes, with easy setup and rapid die changes.

Supported Materials

| Material Type | Supported? | Notes |

|---|---|---|

| Nylon Hook & Loop | ✅ | Standard military and industrial use |

| Polyester Velcro | ✅ | Used in packaging and soft goods |

| Adhesive-Backed | ✅ | Cold cutting prevents glue smearing |

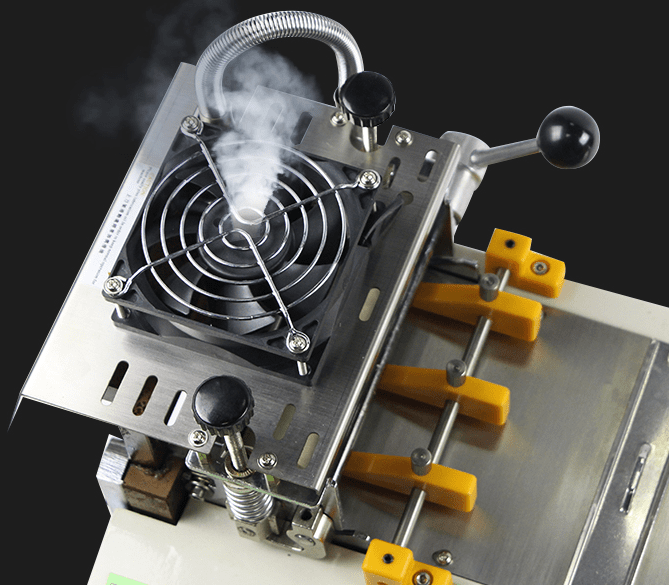

| Eco Velcro | ✅ | Low heat settings prevent material warping |

| Soft Loop Fabric | ✅ | Clean cut without fuzzing |

Customizable Elements

- Die Shape: Circle, square, rounded square, custom logo shapes

- Dot Diameter: 10mm, 15mm, 20mm, 25mm, 30mm+

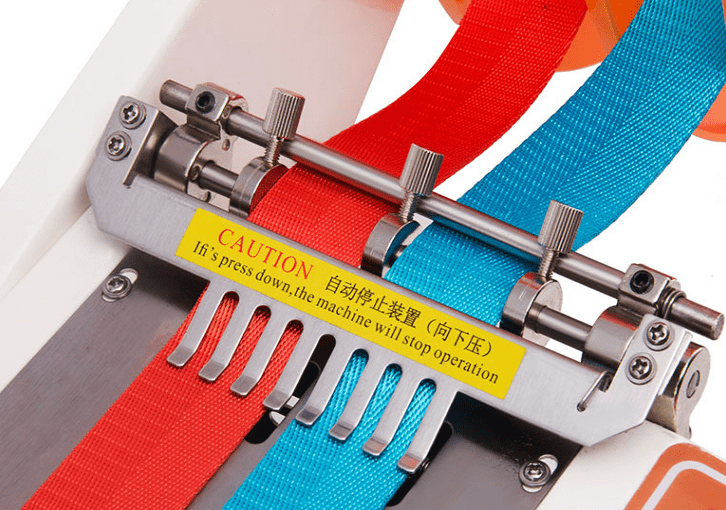

- Cutting Pressure: Adjustable for different material densities

- Speed: Programmable based on batch size and accuracy settings

- Feed Width: Supports narrow (20mm) to wide (150mm+) rolls

With interchangeable rotary dies, it only takes minutes to switch production types — no need for multiple machines.

How does it impact your production workflow?

Think beyond cutting. The roll-to-roll Velcro die cutter isn’t just faster — it also integrates into your entire manufacturing flow.

Our machine can be positioned inline with feeding, laminating, or packaging systems to create a seamless, hands-off production pipeline.

Workflow Impact

| Workflow Step | Manual System | Roll-to-Roll Cutter |

|---|---|---|

| Loading | Frequent stops | Continuous roll feeding |

| Cutting | Manual alignment | Auto sensor control |

| Waste Removal | Manual peeling | Auto waste extraction |

| Output Handling | Batch by hand | Roll rewind or stack output |

| Staffing | 1–2 workers | 0.5 operator (monitor only) |

Real Example: European Textile Factory

- Challenge: High demand for modular Velcro closures in outdoor gear

- Result: Switched from 2 manual cutters to 1 roll-to-roll system

- Gains:

- Tripled weekly output

- Reduced labor by 60%

- Achieved ROI in just 3.5 months

These are the compounding wins that matter in a large-scale setting.

Why choose Suzhou Haoxinhe for roll-to-roll systems?

You don’t just need a machine — you need a trusted supplier who understands logistics, customization, and real factory conditions.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a full-service manufacturer with 5 production lines, CE certifications, and global delivery capability.

What We Deliver

- Turnkey Solutions: Ready-to-run equipment with complete documentation

- Custom Engineering: Machines tailored to your Velcro material and output targets

- Fast Global Delivery: 7–15 day lead times with ocean or air freight

- Post-Sale Support: Remote setup guidance, video training, and live technician help

- Multilingual Sales Team: English, French, Chinese support

- Trusted Worldwide: Clients in Canada, Germany, Italy, Singapore, and more

We also offer a full catalog of cutting machines, including:

- Webbing ribbon cutting machine

- Velcro dot die cutting machine

- Hot and cold cutting machine

- Protective foam cutting machine

- PVC edge banding cutting machine

If you’re building a smart factory — we’re your partner in scalable cutting automation.

Conclusion

A roll-to-roll Velcro die cutter transforms cutting from a bottleneck into a growth engine, enabling large-scale manufacturers to increase output, accuracy, and efficiency — all with one powerful system.

Insights

Large-scale manufacturers who need speed, precision, and automation should invest in a roll-to-roll Velcro die cutting machine. Suzhou Haoxinhe’s rotary cutter delivers 10,000+ cuts/hour with ±0.2mm accuracy, supports various Velcro types, and fits inline with existing production. It’s the fastest path to consistent output and scalable growth in uniform, textile, packaging, and medical industries.

Explore the advantages of roll-to-roll Velcro die cutters for high-speed, efficient production in large-scale manufacturing. ↩ ↩ ↩

Learn how automation in high-volume Velcro production can enhance efficiency and reduce costs significantly. ↩

Discover the various customization options for roll-to-roll die cutters to meet specific manufacturing needs and material types. ↩