Why Is a Roll to Sheet Cutting Machine Essential in Label and Film Manufacturing?

Manual conversion from rolls to sheets creates material waste and inconsistent sizing in label production.

Roll-to-sheet cutting machines1 are essential because they automate high-precision conversion of continuous rolls into ready-to-use sheets, achieving ±0.2mm dimensional accuracy while processing up to 1,200 sheets/hour – impossible with manual methods.

How Does Tension Control Affect Cut Accuracy in Roll to Sheet Processes?

Uncontrolled material tension causes stretching, wrinkles, and misaligned cuts – especially problematic with thin films and delicate labels.

Precision tension control maintains consistent 2-15N material stress throughout cutting, eliminating stretch variations that cause dimensional errors in final sheets. Modern systems use servo-controlled dancers and load cells for real-time adjustments.

Critical Tension Zones in Roll-to-Sheet Conversion

| Process Stage | Optimal Tension Range | Control Method | Impact on Cut Quality |

|---|---|---|---|

| Unwinding | 2-5N | Magnetic brake | Prevents telescoping |

| Pre-Cut | 5-8N | Servo dancer | Eliminates material slack |

| Cutting | 8-12N | Pneumatic clamp | Ensures flat positioning |

| Stacking | 3-5N | Vacuum conveyor | Prevents sheet shifting |

Key Benefits of Modern Roll-to-Sheet Cutters

| Feature | Manual Conversion | Automated Machine | Improvement |

|---|---|---|---|

| Speed | 100 sheets/hour | 1,200 sheets/hour | 12x faster |

| Accuracy | ±2mm | ±0.2mm | 10x more precise |

| Material Waste | 8-12% | 1-3% | 75% reduction |

| Labor Required | 2-3 operators | 0.5 operator | 80% reduction |

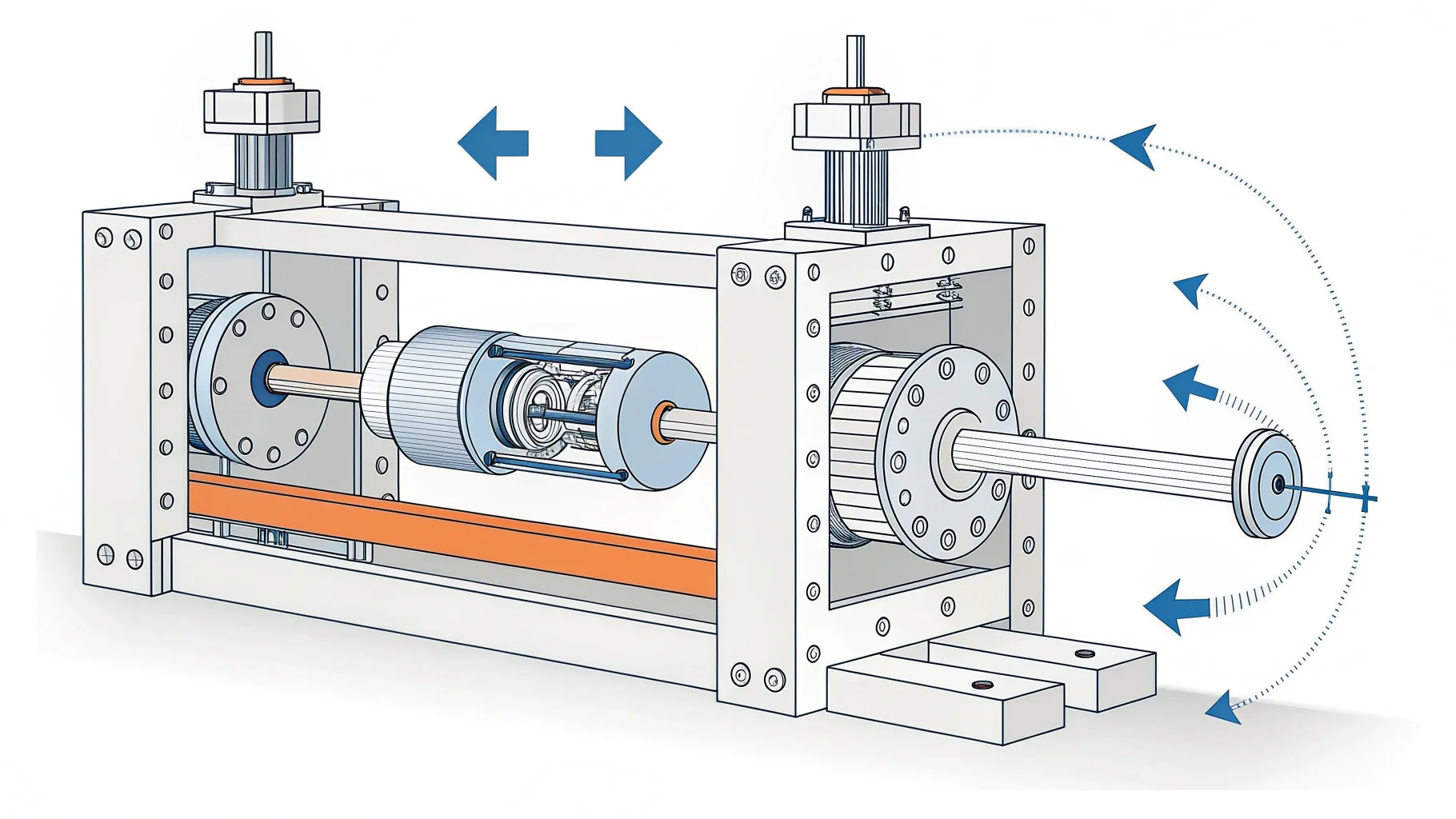

Tension Control System Components

| Component | Function | Benefit |

|---|---|---|

| Servo-Driven Dancer Arm | Maintains constant web tension | Prevents material stretching |

| Load Cells | Measure actual tension force | Enables real-time adjustments |

| Magnetic Particle Brake | Controls unwinding resistance | Eliminates roll overrun |

| Web Guide Sensors | Detect edge position | Maintains ±0.5mm alignment |

Production Example: Our clients report these typical results after switching to automated roll-to-sheet machines:

- Consistent sheet dimensions with less than 0.3mm variation

- Ability to process the thinnest 20micron films without damage

- 30% faster job changeovers with preset tension profiles

Conclusion

Precision roll-to-sheet cutting machines transform flexible material processing through intelligent tension control and automated operation – delivering both speed and accuracy that manual methods cannot achieve.

Insights from HAOXINHE

Having supplied roll processing equipment for decades, we’ve learned that the secret to perfect cuts lies in the first 3 meters of material handling. Our patented SmartWeb™ tension system proactively compensates for material variations before they reach the cutting zone, eliminating rejects at the source. This approach has helped label manufacturers achieve near-zero waste production.

A roll to sheet cutting machine is essential in label and film manufacturing because it efficiently converts large continuous rolls of printed or unprinted material (such as label stock, films, or adhesives) into precisely sized sheets or smaller rolls ready for downstream processing. This machine is crucial for several reasons:

Increased Production Efficiency: It automates the cutting process, enabling high-speed handling of bulk roll materials which significantly reduces production time compared to manual cutting or handling.

Precision and Consistency: The machine provides accurate, clean, and consistent cuts with adjustable cutting widths to match specific label sizes or film requirements. This precision ensures product quality and reduces material waste from incorrect cuts or uneven edges.

Material Versatility: These machines can handle various substrates including paper, films, thin foils, and adhesives used in label manufacturing, making them adaptable for different products and industries.

Explore how these machines enhance efficiency and precision in production processes. ↩