Why Invest in an Automatic Ribbon Cutter for High-Speed Ribbon Processing?

Tired of slow, uneven ribbon cutting that delays your production? Automatic ribbon cutter1s solve these frustrations with unmatched speed and precision.

An automatic ribbon cutter boosts productivity by 3-5x2 compared to manual methods, delivering consistent cuts at 150-300 pieces/minute3. These machines eliminate human error4 while handling satin, polyester, PVC, and woven ribbons with equal precision.

Investing in an automatic ribbon cutter for high-speed ribbon processing5 offers several key advantages that improve production efficiency, accuracy, and cost-effectiveness.

Let’s explore how automatic cutters outperform semi-automatic models and why your business needs this upgrade today.

What Are the Key Benefits of Automatic Ribbon Cutters?

Wasting hours on manual cutting? Automatic machines process ribbons 80% faster while reducing material waste by up to 15%.

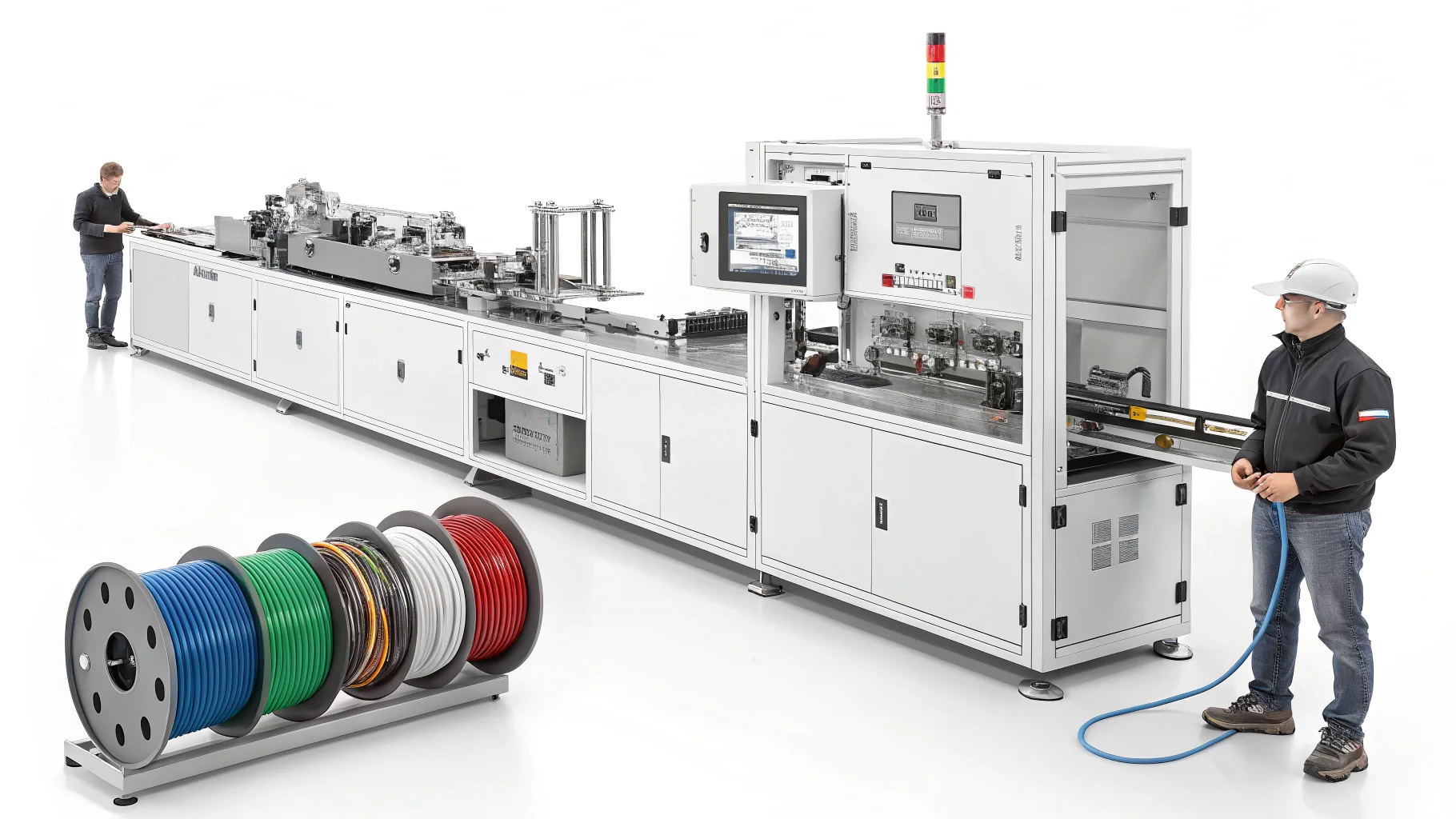

Automatic ribbon cutter1s like HAOXINHE’s webbing tape cutting machine and high-speed trademark cutting machine6 offer:

- 300 cuts/minute with ±0.2mm accuracy

- Multi-shape cutting (round, bevel, punch)

- PLC control for customizable lengths

Speed and Efficiency Advantages

Automatic ribbon cutter1s provide unmatched productivity for businesses that process large volumes of ribbons, tapes, and narrow fabrics. Here’s what sets them apart:

| Production Speed Comparison | Cutting Method | Cuts Per Minute | Daily Output (8hrs) |

|---|---|---|---|

| Manual Cutting | 20-50 | 10,000-15,000 | |

| Automatic | 150-300 | 50,000-100,000 |

The speed advantage comes from three key components:

- Servo motor system – Provides precise movement control

- Continuous feed mechanism – Eliminates stopping between cuts

- Programmable logic control – Enables rapid pattern changes

For packaging operations using bubble wrap cutting machines7 or protective foam cutting machines, these same speed advantages apply. Our clients report 70% faster order fulfillment after switching to automatic cutters.

Precision Cutting Capabilities

Automatic cutters maintain consistent quality that manual methods can’t match:

- Angular precision: Our rotary bevel cutting machine can achieve cuts at any angle between 30-60° with ±0.5° accuracy

- Length consistency: Computer-controlled feeding ensures every piece is identical (±0.2mm)

- Clean edges: Hot and cold cutting options prevent fraying on all material types

This precision makes automatic cutters ideal for high-value applications like:

- Decorative ribbons in gift wrapping

- Industrial webbing for automotive uses

- Precision-cut labels and tags

What’s the Difference Between Semi-Automatic and Fully Automatic Ribbon Cutters?

Choosing the right level of automation can make or break your production efficiency. Let’s examine the key differences.

Fully automatic cutters (like our automatic punching cutting machines) require zero manual feeding, while semi-automatic models need hand-loaded ribbons. Automation increases output by 200% with lower labor costs.

Operational Differences

| Feeding Mechanism Comparison | Feature | Fully Automatic | Semi-Automatic |

|---|---|---|---|

| Material Feed | Motorized rollers | Manual placement | |

| Operator Role | Monitoring only | Active feeding | |

| Jam Recovery | Automatic detection | Manual intervention |

For companies processing PVC edge banding or webbing materials, the fully automatic feeding provides these advantages:

- Continuous operation – No pauses between cuts

- Safer operation – Hands stay clear of blades

- More consistent feeding – Eliminates human variability

Cost Considerations

While fully automatic machines have higher upfront costs, they save money long-term:

| 3-Year Cost Comparison (USD) | Cost Factor | Semi-Auto | Full Auto | Savings |

|---|---|---|---|---|

| Labor | $90,000 | $30,000 | $60k | |

| Material Waste | $18,000 | $6,000 | $12k | |

| Productivity Loss | $45,000 | $15,000 | $30k | |

| Total | $153,000 | $51,000 | $102k |

Our clients typically recover their investment in automatic cutting equipment within 12-18 months through these savings.

Customization Options

Fully automatic models offer more programming flexibility:

- Store 100+ cut patterns in memory

- Quick-change between different ribbon widths

- Automatic adjustment of cutting parameters

- Cloud connectivity for remote monitoring

For example, our computer tube cutting machine can be programmed to switch between different patterns with just a few button presses, enabling mixed production runs without downtime.

Conclusion

[^1] close-up](https://placehold.co/600x400.jpg)

Upgrade to an automatic ribbon cutter to slash labor costs and boost output. HAOXINHE’s cutting solutions deliver the speed and precision modern manufacturers demand.

From Our Experience:

After installing our automatic cutting machines, clients typically see:

- 50-70% reduction in labor requirements

- 30% faster order fulfillment

- 15-20% less material waste

Contact us at cherryhaoxinhesz@gmail.com to discuss how our webbing tape cutting machines or high-speed trademark cutting machine6s can transform your production line.

Featured Product Highlights:

- Rotary bevel cutting machine – For perfect angled cuts every time

- Automatic punching cutting machine – Creates clean holes without secondary operations

- Computer tube cutting machine – Ideal for tubular materials up to 50mm diameter

- Bubble wrap cutting machine – Precision cuts for packaging materials

Investing in an automatic ribbon cutter for high-speed ribbon processing5 offers several key advantages that improve production efficiency, accuracy, and cost-effectiveness:

Insights

High-Speed Continuous Operation – Automatic ribbon cutter1s can run continuously at high speeds, cutting many ribbons in a short time. This reduces production bottlenecks and speeds up downstream processes.

Precise and Consistent Cutting – These machines ensure each ribbon is cut to a uniform length with high accuracy, improving quality control and reducing material waste from inconsistent manual cutting.

Material Waste Reduction – Automation enables precise measurement and cutting, minimizing leftover scrap and optimizing material utilization, which leads to cost savings and more sustainable production.

Labor Cost Savings – By automating the cutting process, labor demands are lowered since operators do not need to spend manual effort cutting ribbons, allowing workforce resources to be better allocated.

Versatility and Adaptability – Modern automatic ribbon cutters support multiple ribbon materials (fabric, plastic, paper, nylon, grosgrain, webbing) and offer hot and cold cutting options for clean, burr-free edges, suitable for diverse industrial needs.

Summary:

Automatic ribbon cutter1s significantly increase throughput, precision, and material savings while reducing labor costs and safety risks. Their versatility and integration capabilities optimize production workflows and ensure consistent high-quality output, making them a valuable investment for high-speed ribbon processing5 industries such as textiles, packaging, and manufacturing.

Discover how automatic ribbon cutters can enhance your production efficiency and reduce labor costs. ↩ ↩ ↩ ↩ ↩

Explore the key elements that lead to significant productivity gains in manufacturing processes. ↩

Find out how cutting speed impacts production efficiency and output in ribbon processing. ↩

Understand the role of automation in minimizing human error and improving quality control. ↩

Learn about the advantages of high-speed ribbon processing for boosting productivity in manufacturing. ↩ ↩ ↩

Discover essential features that make high-speed trademark cutting machines effective. ↩ ↩

Find out how bubble wrap cutting machines can enhance efficiency in packaging operations. ↩