Why are webbing rotary bevel cutting machines preferred in industrial strap fabrication?

Manual cutters can’t keep up with modern industrial demands for precision, speed, and clean angled cuts.

Webbing rotary bevel cutting machines are preferred in industrial strap fabrication because they deliver faster, cleaner, and more consistent cuts — essential for large-scale manufacturing.

In my factory, we’ve seen how switching to bevel cutting technology transformed the output, especially when dealing with complex materials like Velcro and elastic straps. Let me walk you through why this technology is becoming the industry standard.

What materials are best suited for bevel rotary cutting technology?

Struggling to cut synthetic straps without fraying or melting? You’re not alone.

Bevel rotary cutting machines are ideal for synthetic and technical textiles — such as nylon webbing, polypropylene straps, Velcro, elastic bands, and insulation tapes — due to their precision and heat-resistance control.

Bevel rotary blades are uniquely designed to handle tension-sensitive and synthetic webbing materials. The rotating blade edge slices diagonally rather than vertically, which distributes pressure evenly and minimizes fabric distortion or burn marks.

Materials That Perform Best with Rotary Bevel Cutting:

| Material Type | Application Examples | Why It’s Ideal for Bevel Cutting |

|---|---|---|

| Nylon Webbing | Outdoor gear, safety harnesses, luggage straps | Clean edge cuts, minimal fray |

| Polypropylene Straps | Packaging, medical banding, insulation | Maintains shape, avoids melting |

| Velcro (Hook & Loop) | Military gear, sportswear, cable management | Precise cutting, soft angle trimming |

| Elastic Bands | Garments, medical use, masks | Preserves elasticity without damage |

| Insulation Tapes | HVAC, automotive, electronics | Consistent cut angle, minimal edge residue |

| Printed Label Tapes | Branding tags, size labels, logo labels | Protects printed surfaces, exact dimensions |

Why Flat Cutting Fails for These Materials

Flat blade cutting machines often apply direct downward pressure and heat. This causes:

- Fraying of woven synthetic fibers

- Edge melting, especially in tight-density tapes

- Inconsistent lengths, due to slippage or stretch

Rotary bevel blades, especially those integrated into HAOXINHE machines, solve these problems with a continuous cutting motion that matches the fabric’s tension profile.

Our Solution in Action

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we’ve tailored our rotary bevel cutting machine for a wide range of flexible, strip-shaped materials. One of our clients from the packaging industry in Singapore needed to cut 25,000 meters of PP straps weekly — while preserving edge quality and color print. Their old system caused 7% material loss.

After switching to our bevel cutter, waste dropped to less than 1%. The added precision allowed them to cut printed tapes without image distortion or misalignment.

How the Machine Works

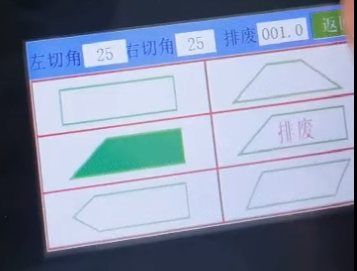

Our rotary bevel machines combine:

- A high-speed rotary blade

- Adjustable cutting angles

- Conveyor feeding system for batch automation

- PID heat control for heat-seal cutting (optional)

This setup ensures consistent cutting for even the most delicate materials.

Conclusion

Bevel rotary cutting machines handle delicate synthetic materials with unmatched speed and precision.

Insights

HAOXINHE’s rotary bevel cutting machines are specifically engineered to process a wide range of technical and synthetic materials with accuracy and minimal waste. As part of Suzhou Haoxinhe Electrical Equipment Co., Ltd.’s lineup, these machines have helped B2B clients across Europe and North America streamline their strap fabrication lines. Whether you cut nylon webbing, printed labels, or PP insulation tapes, this technology delivers reliability at scale.

Keyword Summary: rotary bevel cutting machine, webbing cutting equipment, nylon strap cutting, Velcro cutter, HAOXINHE, Suzhou Haoxinhe Electrical Equipment Co., Ltd., industrial tape cutter, bevel edge cutter