Which PVC sheet cutter best tackles multi-layer industrial insulation sheets?

Multi-layer insulation sheets made from PVC or composite materials are tough to cut cleanly—standard blades jam, warp, or burn through them.

The best PVC sheet cutters1 for multi-layer insulation are rotary bevel cutting machines2 and automatic punching cutters3 with programmable depth control4 and reinforced blade assemblies5.

We’ve worked with clients in the HVAC and chemical industries who handle thick PVC laminates daily. When they switched to our industrial cutters with servo precision and depth calibration, their throughput jumped—and rework nearly disappeared.

Which PVC sheet cutter best tackles multi-layer industrial insulation sheets?

Cutting thick, layered PVC insulation sheets manually leads to jagged edges, uneven layers, and damaged material cores.

Rotary bevel cutters and automatic punching cutting machines are ideal for clean, accurate cuts on multi-layer PVC insulation sheets used in industrial applications.

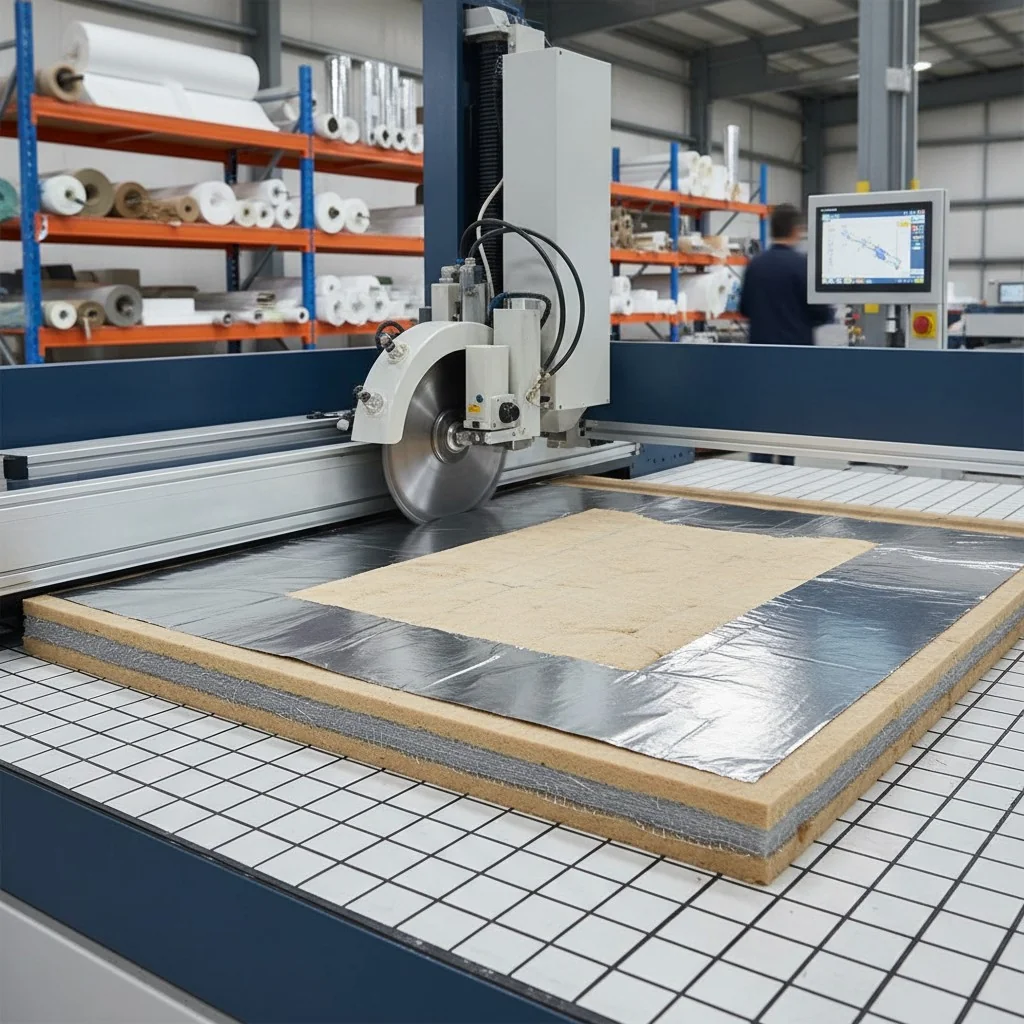

Multi-layer PVC insulation is often used in data centers, chemical plants, and HVAC systems. These sheets can include foamed PVC, aluminum foil, fiberglass mesh, and adhesive layers—making them difficult to cut with regular equipment.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we’ve developed machines specifically to handle these composites. Our rotary bevel cutting machine is built with:

- Programmable cutting depth

- Multi-layer alignment guides

- Reinforced rotary blades

- Cooling air output to reduce friction

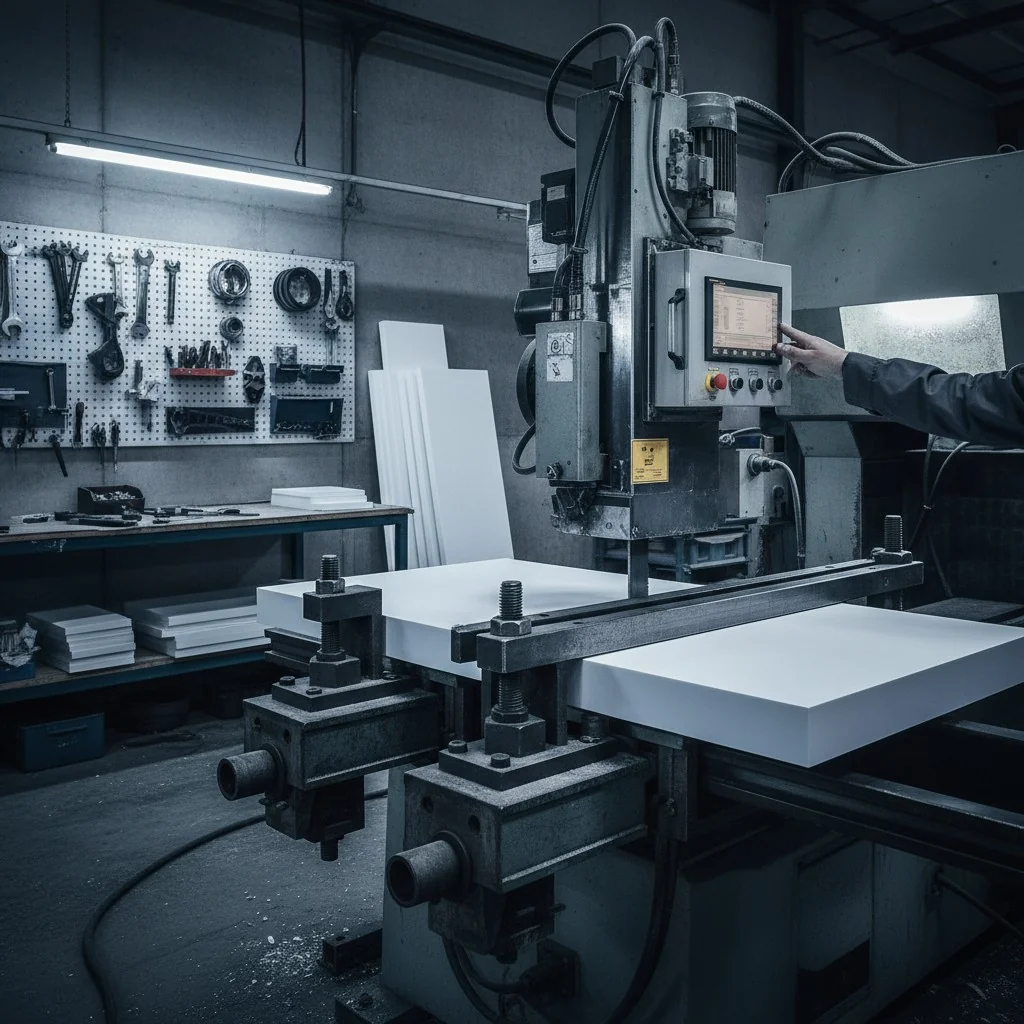

We also recommend our automatic punching cutting machine for thick sheet applications, especially when you need repeated hole or notch patterns.

Common Use Cases for Multi-Layer PVC Sheet Cutting

| Application | Recommended Machine |

|---|---|

| HVAC duct insulation sheets | Rotary bevel cutting machine |

| Fire-retardant PVC board | Round shape cutting machine |

| PVC + aluminum laminated sheet | Automatic punching cutting machine |

| Protective barrier foams | Protective foam cutting machine |

Key Features You Should Look For

- Sheet Stabilizers: Hold thick or foamed sheets flat during cutting.

- Multi-pass Precision: Allows gradual cutting across layers, reducing pressure damage.

- Laser Alignment: Ensures edge accuracy, especially for repeated panel dimensions.

- Edge Trimming Modules: Clean up outer sheet burrs post-cut.

Our clients in Europe, especially those in thermal insulation manufacturing, have integrated our PVC edge banding cutting machine to clean-cut both rigid and flexible PVC sheets.

How do you prevent melting when cutting thick rigid PVC sheets?

Cutting rigid PVC sheets often leads to melting or edge discoloration due to high blade friction or uncontrolled heat buildup.

To avoid melting, use low-speed cold blades, sharp rotary cutters, and airflow cooling attachments. Avoid hot blades unless temperature is precisely regulated.

PVC has a low melting point, especially under friction. When cutters move too fast or with dull blades, they generate surface heat. That results in melted edges, rough burrs, and even tool sticking.

In our machines at Haoxinhe, we’ve addressed this in both mechanical and electronic ways.

Key Techniques to Avoid Melting PVC

1. Cold Cutting with Sharp Blades

All of our webbing ribbon cutting machines and PVC edge banding cutting machines come standard with:

- Hardened steel cold blades

- Replaceable rotary options

- Servo-driven blade depth control

Using sharp blades prevents the need for high pressure or speed, which are the primary causes of friction.

2. Feed Rate and Speed Control

Cutting thick PVC at high speed is a mistake. You want slow and consistent blade movement.

Our machines allow adjustable feed rates via touchscreen control. Operators can slow the blade when cutting dense areas or multiple layers.

3. Air Cooling and Heat Dispersion

We equip many of our cutters with nozzle-based airflow cooling. This actively cools the blade and surface as it cuts. You can also install aftermarket fans near the blade to dissipate heat.

4. Multi-Pass Cutting

Instead of cutting all the way through in one go, our computer tube cutting machines support multi-layer slicing. The blade descends incrementally per pass, giving cleaner edges.

| Cutting Strategy | Effectiveness | Melting Risk |

|---|---|---|

| High-speed, single pass | Fast but rough | High |

| Slow, multi-pass | Precise | Low |

| Heated blade + control | Clean (for foams) | Medium (if misused) |

| Cold blade + airflow | Very clean | Very low |

Avoid These Common Mistakes

- Using hot knife blades on rigid PVC

- Cutting with dull blades

- Running at full-speed feed with thick sheet stock

- Forgetting to clean buildup on blade tips (causes friction)

When clients order our bubble wrap cutting machine or protective foam cutting machine for packaging lines, we always recommend material-specific blade tuning—especially for clients using layered or foamed PVC in lining sheets.

Conclusion

Proper machine choice and cutting setup prevent waste and material damage when processing thick PVC insulation sheets.

🧠 Industry Insight: Why Standard Cutters Fail on PVC Insulation Sheets

From my hands-on experience with industrial insulation clients, I’ve seen more production losses caused by PVC sheet cutting than almost any other operation. The problem? Most factories try to use standard guillotines or CNC routers built for wood or foam. These tools don’t account for the layered complexity—PVC bonded with foil, mesh, or foam creates resistance that warps or melts under the wrong pressure or speed.

That’s why we engineered our rotary bevel and automatic punching cutters3 with multi-pass logic and airflow cooling. One client in Germany producing fire-retardant HVAC panels saw a 70% reduction in edge rework by switching to a rotary blade setup with programmable depth descent.

Precision isn’t just about blade sharpness—it’s about how the blade interacts with layered substrates. Servo pressure control, slow-feed slicing, and active blade cooling are game changers. With thick or adhesive-backed materials, a single pass at the wrong speed can cost hundreds in wasted sheets.

Bottom line: if you’re cutting layered PVC like it’s cardboard, you’re not just damaging material—you’re burning through your margins. Smart cutting is smart business.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers industry-specific PVC cutting solutions for insulation, packaging, and lining applications. Our rotary, cold-blade, and servo-controlled cutting machines prevent melting and ensure clean, repeatable cuts—even in complex multi-layer setups. Perfect for HVAC, lab, and industrial plant contractors looking to scale production without sacrificing quality.

Explore this link to discover top-rated PVC sheet cutters that ensure clean and precise cuts for industrial applications. ↩

Find out how rotary bevel cutting machines can enhance your cutting process for multi-layer materials. ↩

Discover the efficiency and precision of automatic punching cutters for handling thick PVC sheets. ↩ ↩

Understand the importance of programmable depth control in achieving consistent and accurate cuts. ↩

Explore the benefits of reinforced blade assemblies for durability and performance in cutting machines. ↩