Which industries benefit most from adopting automatic belt cutting machines?

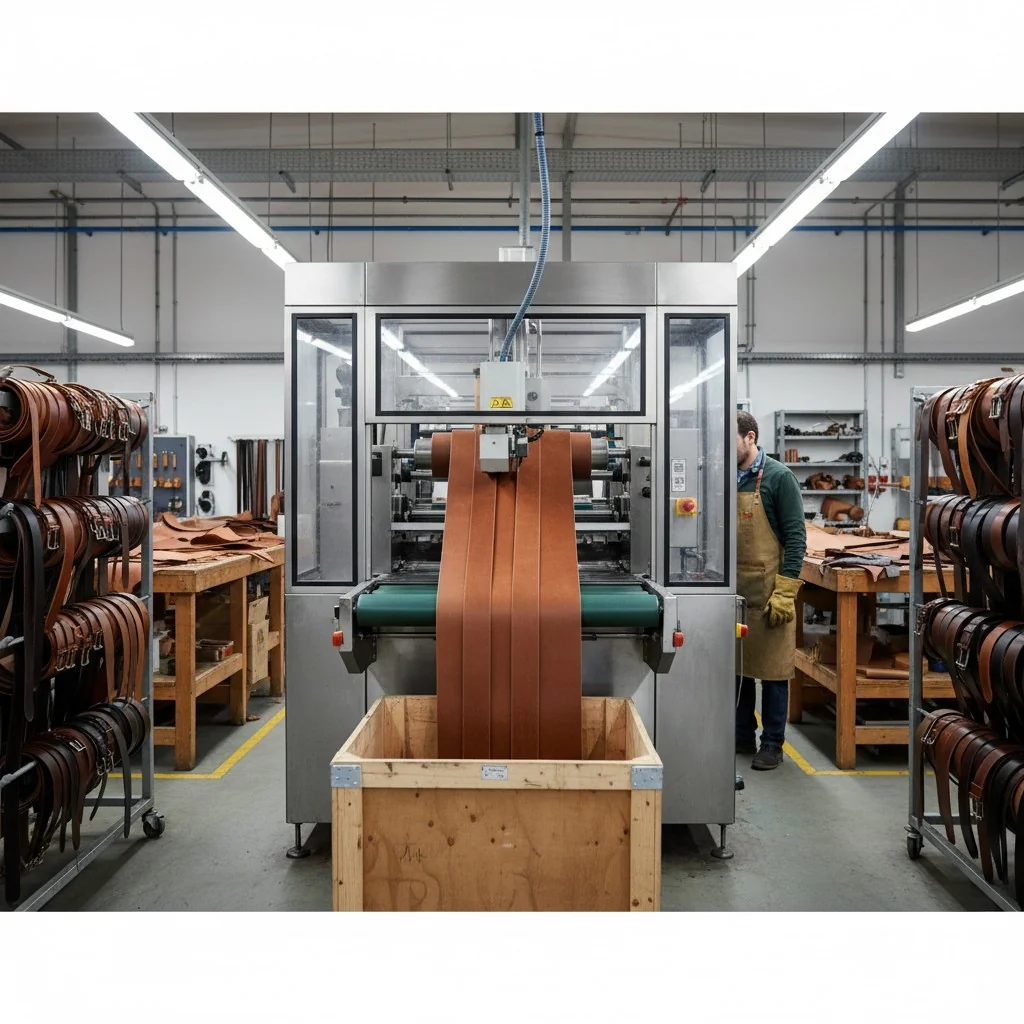

Manual cutting solutions are no longer scalable for industries that deal with high volumes of flexible materials.

Industries like automotive, packaging, HVAC, medical, textile, and electronics benefit most from automatic belt cutting machines due to their need for speed, precision, and material efficiency.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd.1, we’ve worked with clients across sectors who upgraded to our HAOXINHE2 automatic belt cutting machines3 — and their production lines were transformed.

What materials can be processed with automatic belt cutting systems for industrial applications?

Many factories still struggle to cut diverse materials with one machine setup — wasting time and resources on manual switches and retooling.

Automatic belt cutting machines can process a wide variety of strip-shaped and flexible materials such as nylon webbing, PP straps, Velcro, insulation tapes, PVC edge banding, foam padding, and elastic bands.

The beauty of these machines lies in their modular design. With adjustable speed, temperature, and blade configurations, they handle both delicate and dense industrial materials with equal precision.

Core Material Types Compatible with HAOXINHE2 Belt Cutting Machines

| Material | Application | Special Machine Feature |

|---|---|---|

| Nylon Webbing | Automotive, outdoor gear, safety harnesses | Sealed edges via heat cut |

| Polypropylene (PP) Straps | Packaging, agriculture, logistics | Cold cut to prevent distortion |

| Velcro (Hook & Loop) | Military, sportswear, cable bundling | Precise length matching, hot seal |

| Elastic Bands | Garments, medical masks, activewear | Stretch-sensitive feeding system |

| Insulation Tapes | HVAC, electronics, automotive assembly | Tension control with heat adjustment |

| PVC Edge Banding | Furniture, cabinetry, interior decor | Clean cuts without edge melting |

| Protective Foam | Packaging, electronics, medical equipment | Wide blade, soft material feed rollers |

| Printed Label Tapes | Branding, compliance, retail tags | Cut without smudging or misalignment |

HAOXINHE2 machines offer programmable profiles for each of these materials. Once the operator selects the material, the system auto-adjusts feed speed, blade RPM, and temperature settings.

Industries That Use These Materials

Let’s explore where these materials go and why cutting accuracy matters:

1. Automotive Industry

- Materials: Nylon webbing, Velcro, insulation tapes

- Why: Seat belts, sound dampening layers, cable straps require exact cuts with sealed edges.

2. Medical & Pharmaceutical

- Materials: Elastic bands, medical tapes, protective foam

- Why: Precise length is critical for product fit and packaging standards.

3. Textile & Apparel

- Materials: Elastic bands, PP ribbons, woven tapes

- Why: Garment assembly lines demand consistent and scalable cuts.

4. HVAC & Electrical

- Materials: Insulation tapes, printed label tapes

- Why: Safe installations depend on accurate tape sizing and clean seals.

5. Packaging & Logistics

- Materials: PP straps, protective foam, edge banding

- Why: High volumes and tight packing tolerances require speed and uniformity.

6. Outdoor & Safety Gear

- Materials: Heavy-duty nylon webbing, Velcro

- Why: Fray-free cuts improve safety and product durability.

Case Example: Logistics Gear Manufacturer (Singapore)

One of our clients in Singapore needed to cut multiple types of materials — from soft elastic to rigid PP straps — for their packaging and transport accessory line.

They previously used two different machines and switched blades manually between batches.

We supplied them with a customized HAOXINHE2 automatic belt cutting system with:

- Dual-temperature blade modules

- Auto blade changeover

- Pre-programmed material presets

The result?

- 30% reduction in machine downtime

- 60% increase in total daily output

- 99% cutting accuracy across material types

Conclusion

Automatic belt cutting machines support a broad range of materials — enabling various industries to scale with precision and flexibility.

Insights

Suzhou Haoxinhe Electrical Equipment Co., Ltd. designs automatic belt cutting machines to serve the unique needs of multi-material, high-output industrial applications. Whether it’s nylon straps for automotive, foam for packaging, or medical tapes for healthcare, our HAOXINHE machines adapt to your production requirements with pre-set programs, precise temperature controls, and flexible feeding systems. This versatility makes our solutions ideal for B2B clients across North America, Europe, and Southeast Asia.

Keyword Summary: automatic belt cutting machine, HAOXINHE, Suzhou Haoxinhe Electrical Equipment Co., Ltd., webbing tape cutter, industrial strap cutter, Velcro cutting machine, PP strap processing, insulation tape cutter, foam cutting, elastic band machine