Which bubble wrap cutting machine type is better for thick film?

Cutting thick bubble wrap film often causes headaches: jagged edges, split seams, or costly downtime when machines can’t keep up.

For bubble wrap films above 100 microns, hot-knife cutters give superior sealed edges, while rotary blades are cheaper to maintain but less effective on edge quality.

- Best Cutter for Thick Bubble Wrap Film: A heavy-duty slide cutter with a sharp, replaceable razor blade handles thick film better than basic options.

- Industrial-Grade Solutions: For high-volume, consistent cutting, automated machines1 with band knives or cutoff blades are most effective.

- Avoid Standard Tools: Box cutters or film cutters2 often fail with thick film, causing uneven cuts or tearing.

- Upgrade Tip: Choose equipment designed for bulk material to ensure smooth, clean results and improve cutting efficiency.

- Professional Choice: For thick bubble wrap, invest in precision tools built for industrial performance and longevity.

This choice is not only about cutting power. It impacts the safety of your packaging, waste rates, and the reliability of your production line. Let’s compare them in detail.

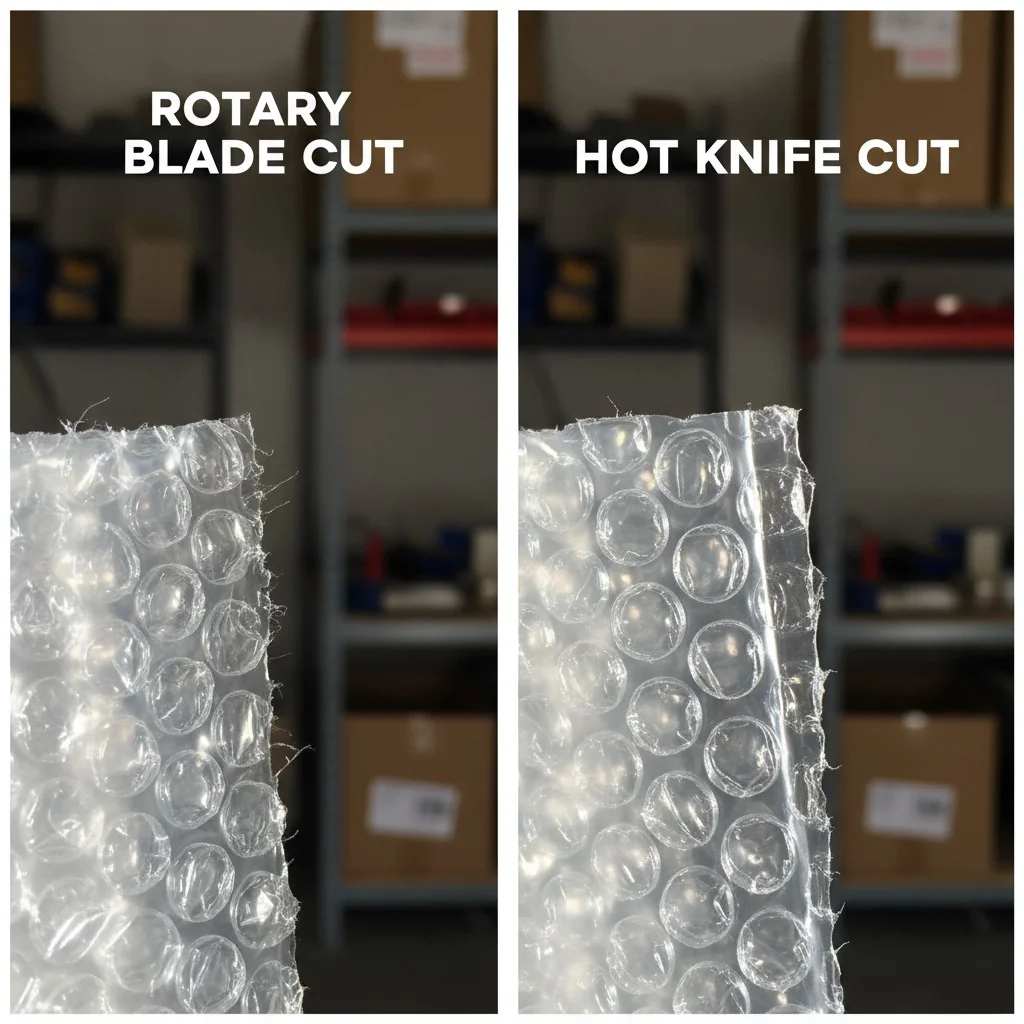

Rotary blade vs hot-knife for ≥100 micron air bubble film (edge quality & maintenance)

Thicker bubble films demand more precision. If the cut is rough, packaging looks unprofessional and risks tearing during transport.

Hot-knife systems are better for clean sealed edges on ≥100 micron film, while rotary blades are more durable with lower maintenance costs.

Here’s how each performs:

Rotary Blade Cutters3

Rotary blade cutters use a hardened circular blade rolling against the film, like a shear.

Pros

- Handles dense multilayer films without heating.

- Low operating cost—blades are cheap to resharpen or replace.

- Few electronic parts, so breakdowns are rare.

Cons

- Struggles with ≥100 micron air bubble film.

- Edges can fray or split under stress.

- Sharp burrs make it less safe for packaging fragile goods.

Maintenance

- Sharpen or replace blades every 3–6 months.

- Regular lubrication and alignment checks needed.

Hot-Knife Cutters4

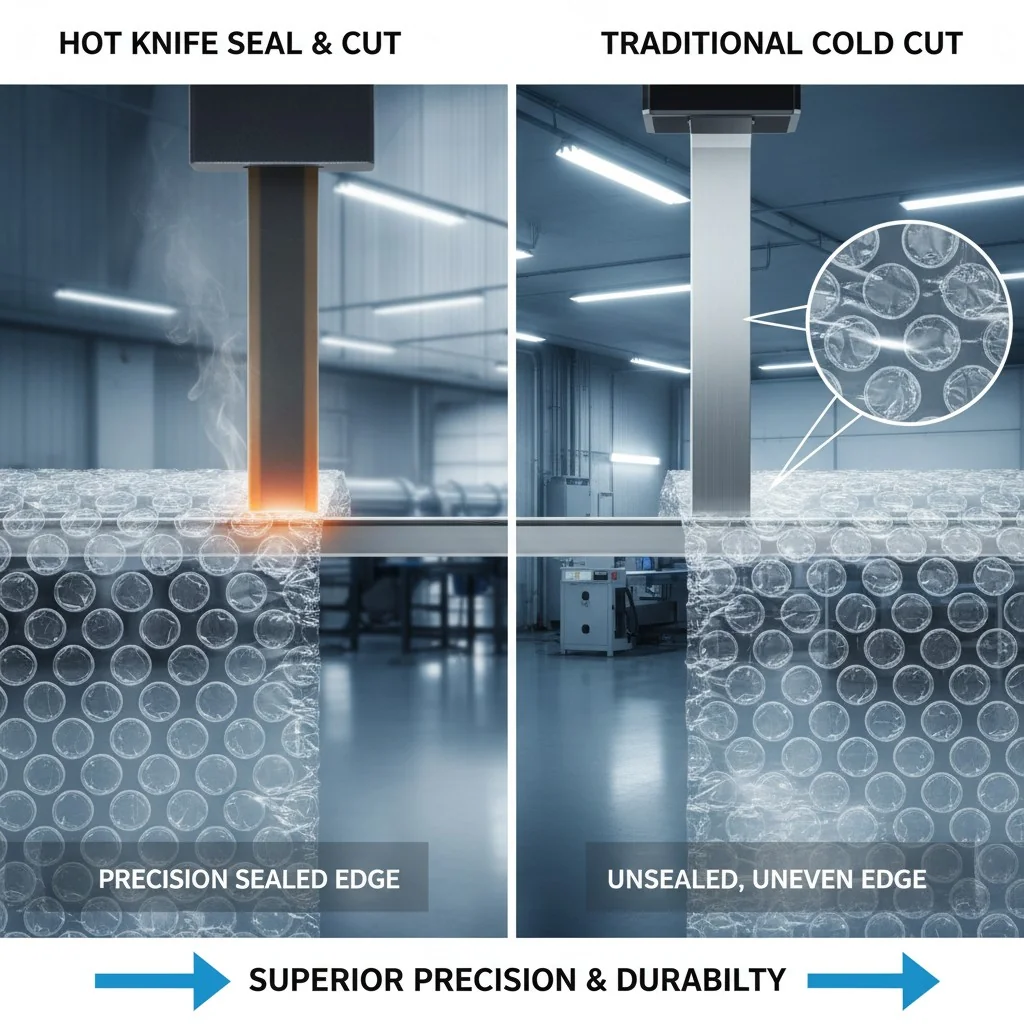

Hot-knife cutters melt through plastic, sealing the cut edge instantly.

Pros

- Smooth sealed edges with no fraying.

- Ideal for thick films ≥100 microns.

- Improves packaging appearance and strength.

Cons

- Heating elements wear out every 12–18 months.

- Higher electricity consumption.

- Needs frequent cleaning to remove melted residue.

Maintenance

- Clean knife after every shift.

- Replace heating rods/wires when cut quality drops.

Side-by-Side Comparison

| Factor | Rotary Blade | Hot-Knife |

|---|---|---|

| Edge Quality | Fair, can fray | Excellent, sealed, smooth |

| Thick Film Handling | Limited beyond 100 micron | Excellent for ≥100 micron |

| Maintenance Cost | Low (blade sharpening) | Moderate (heater replacement) |

| Downtime Risk | Low | Medium (heating failure possible) |

| Energy Use | Low | Higher |

| Safety | Sharp burrs possible | Safer, sealed finish |

Real-World Example

One of our clients in Germany packaging industrial tools used rotary blades for 120-micron bubble wrap. They faced constant customer complaints about torn packaging. After upgrading to a HAOXINHE Hot Knife Bubble Wrap Cutting Machine with PLC control, they cut material waste by 18% and eliminated edge tear issues.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we also build dual-mode systems that combine rotary + hot-knife options. This gives factories flexibility: rotary for low-cost maintenance, hot-knife for thick-film precision.

Conclusion

For thick bubble wrap above 100 microns, hot-knife cutters are the better choice for edge quality, while rotary blades remain useful for durability and low-maintenance needs.

🧠 Industry Insight: Best Cutter Type for Thick Bubble Wrap Film (100+ Microns)

Over the years, we’ve tested hundreds of machines across Asia and Europe, and one thing is clear: when cutting thick bubble wrap5 (100 microns and up), edge integrity makes or breaks your packaging performance. Many factory managers underestimate the stress points created by frayed or poorly cut film edges—especially during long-distance shipping.

Rotary blades, while economical and easy to maintain, are mechanically limited at this thickness. We’ve seen clients try to boost pressure to "force the cut," only to warp the rollers or increase gear backlash over time. Even more concerning: a jagged edge can scratch or puncture sensitive electronics during transit.

That’s where hot-knife systems dominate. The sealed edge is not just cosmetic—it strengthens the cut end, minimizes film separation, and prevents moisture intrusion. For any product line where aesthetics or impact protection matter (think e-commerce, electronics, medical packaging), a hot-knife is non-negotiable.

One insider trick? Opt for ceramic-coated hot knives if you run 2–3 shifts daily. They resist residue buildup far better than standard metal blades, saving hours in daily cleaning.

In protective packaging, clean cuts aren’t just about looks—they’re a frontline defense against damage claims.

Factories cutting ≥100 micron bubble wrap film should use hot-knife cutting machines for reliable, sealed edges that prevent waste and damage. Suzhou Haoxinhe Electrical Equipment Co., Ltd. designs Bubble Wrap Cutting Machines6 and Protective Foam Cutting Machines with PLC controls, customizable widths, and dual cutting modes, giving manufacturers an efficient solution for thick protective packaging films.

Discover how automated machines can streamline your production process and improve cutting consistency. ↩

Learn why standard tools like box cutters can lead to uneven cuts and increased waste in your packaging. ↩

Understand the differences between rotary blade cutters and hot-knife cutters for better decision-making. ↩

Explore the benefits of hot-knife cutters for achieving clean, sealed edges on thick bubble wrap. ↩

Explore best practices for cutting thick bubble wrap to ensure quality and minimize waste. ↩

Discover essential features to consider when selecting bubble wrap cutting machines for your production needs. ↩