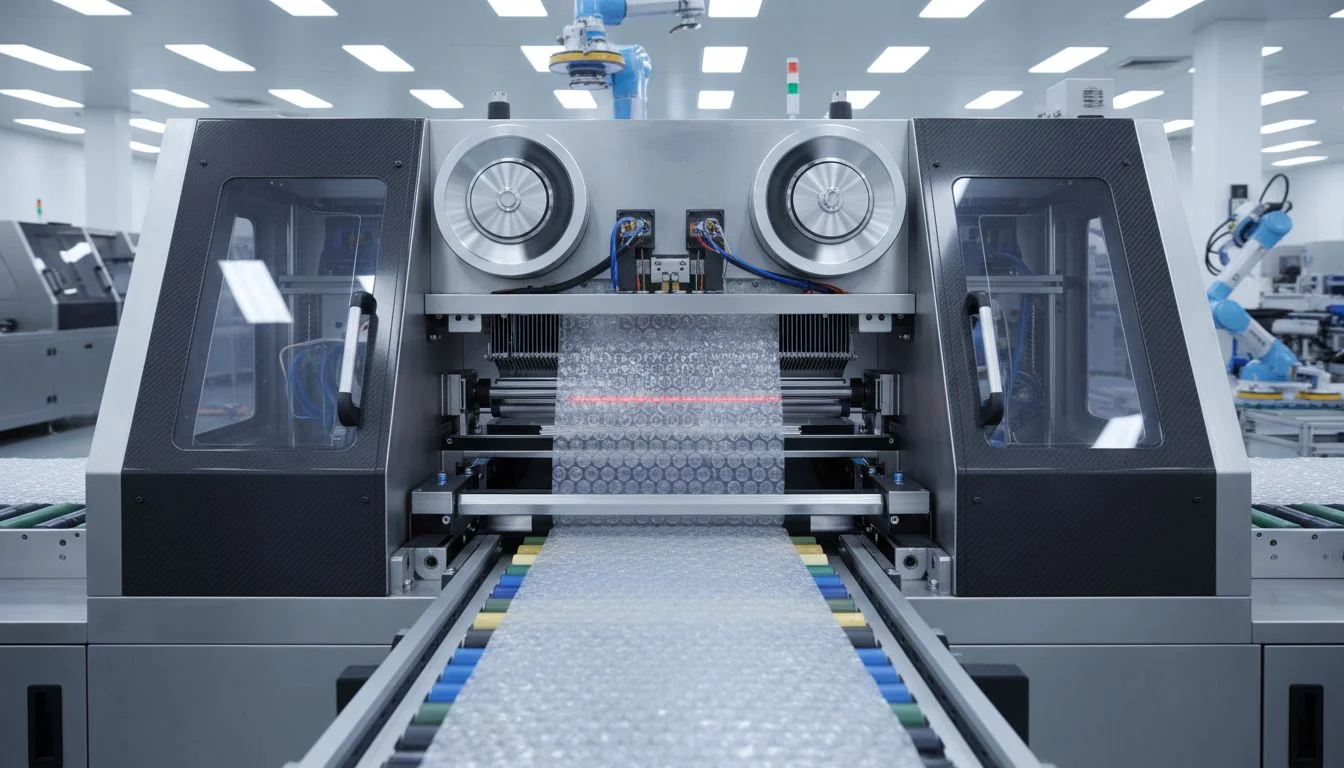

Which Bubble Wrap Cutting Machine Is Best? Full Comparison of 10 Popular Models

Not sure which bubble wrap cutting machine1 to invest in?

This 2026 comparison guide evaluates the 10 most popular models across cost, speed, material compatibility, and reliability to help you choose the best.

Whether you’re sourcing for a packaging factory, fulfillment center, or reselling under your brand, this side-by-side breakdown saves you hours of research.

What does "best" mean when choosing a bubble wrap cutting machine1?

Paying more doesn’t always mean better quality.

The best bubble wrap cutting machine is one that meets your production volume, material needs, and budget—without compromising on durability or support.

From conversations with factory buyers like Mark Chen, I’ve found the top considerations are cutting accuracy, automation level, machine uptime, and certified support for exports. Machines from Suzhou Haoxinhe Electrical Equipment Co., Ltd. consistently stand out due to their performance-to-price ratio, particularly for bulk buyers in Canada and Europe.

🔍 Key Evaluation Criteria

| Factor | Importance |

|---|---|

| Cutting Speed | Affects output per hour |

| Material Compatibility | Foam, film, wrap, edge banding support |

| Maintenance & Support | Impacts long-term cost and downtime |

| Certifications | Critical for import/export compliance |

| Price & ROI | Determines cost-effectiveness over 12–24 months |

Side-by-Side Comparison of 10 Leading Models

Here’s a detailed comparison table of the most requested bubble wrap cutting machine1s in 2025.

| Model | Price | Speed (m/min) | Auto Feed | Materials Supported | Certifications | Ideal User |

|---|---|---|---|---|---|---|

| HX-F350 | $4,500 | 35 | ✅ | Bubble wrap, PVC, foam | CE, ISO | Mid-size factories |

| TRX-1000 | $8,200 | 45 | ✅ | Bubble wrap, foam | CE | High-volume export packaging |

| ZT-BWC500 | $6,800 | 40 | ✅ | Bubble wrap, shrink film | CE | Large fulfillment centers |

| KQ-FCUT | $7,600 | 42 | ✅ | EVA, foam, bubble wrap | CE | Multi-product production lines |

| YS-PWM550 | $9,000 | 50 | ✅ | Pharma-grade bubble wrap & film | CE, GMP-ready | Pharma, HVAC exporters |

| SC-300 | $6,000 | 36 | ✅ | Foam, lab wrap, chemicals | CE | Safety-priority factories |

| RZ-CutPro | $5,900 | 38 | ✅ | Kraft paper, bubble wrap | CE | Precision-focused departments |

| WP-AutoWrap | $7,900 | 41 | ✅ | Bubble wrap + edge banding | CE | Furniture & appliance factories |

| JT-CW350 | $5,300 | 32 | ✅ | Bubble wrap only | CE | Budget-sensitive factories |

| PX-B350 | $5,200 | 34 | ❌ | Foam wrap | Basic | Entry-level manufacturing |

Which machine is best for YOUR situation?

Still unsure which machine fits your needs? Here’s a breakdown based on your operation type.

🏭 For Medium-Sized Packaging Factories

🏆 Best Pick: HX-F350 by HAOXINHE

Offers excellent ROI, supports multiple materials, CE certified, and priced competitively.

🏪 For E-Commerce Fulfillment Centers

🏆 Best Pick: ZT-BWC500

Fast, compact, easy-to-integrate with conveyors and auto packing lines.

🧪 For Pharmaceutical & Medical Packaging

🏆 Best Pick: YS-PWM550

High-precision, sterile cutting with CE and GMP-ready design.

🛋️ For Edge Banding + Bubble Wrap Tasks

🏆 Best Pick: WP-AutoWrap

Combines two machines into one. Saves time and space in diverse manufacturing lines.

💰 For Buyers on a Budget

🏆 Best Pick: JT-CW350

Affordable, simple to operate, and comes with automation features rarely found in its price range.

Expert Review: Why HX-F350 Is the Most Balanced Option

If I had to recommend just one machine for most general factory settings, it would be the HX-F350 from Suzhou Haoxinhe Electrical Equipment Co., Ltd. Here’s why:

✅ What It Does Well:

- Multi-material support: Bubble wrap, foam, PVC edging

- Consistent speed: 35 m/min, ideal for factories shipping daily

- User-friendly: Simple control panel and low training curve

- Certifications included: CE and ISO, no hidden export hurdles

- Customizable: Haoxinhe can tailor dimensions, feed lengths, and blade types

It’s especially valuable for clients like Mark Chen who need reliable cutting machines for repackaging and distribution businesses in Canada.

Conclusion

Each of these 10 machines serves a unique type of buyer—what matters is choosing one that fits your workflow, not just the most expensive or high-tech.

Insights

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we’ve supplied cutting solutions to factories, fulfillment centers, and B2B buyers across North America, Europe, and Southeast Asia. Our HX-F350 Bubble Wrap Cutting Machine remains a top seller thanks to its durability, customization, and excellent performance-to-cost ratio. With five production lines, CE certifications, and tailored export packaging, we ensure that your machine arrives ready to work—so your operations never fall behind.