Which blade technologies deliver the cleanest cuts in industrial PVC foam cutting machines?

PVC foam is tricky to cut — the wrong blade leaves rough edges, heat marks, or wasted material.

Oscillating blades, carbide-tipped rotary blades, and hot wire blades each produce clean PVC foam cuts, with oscillating blades offering the most balanced performance.

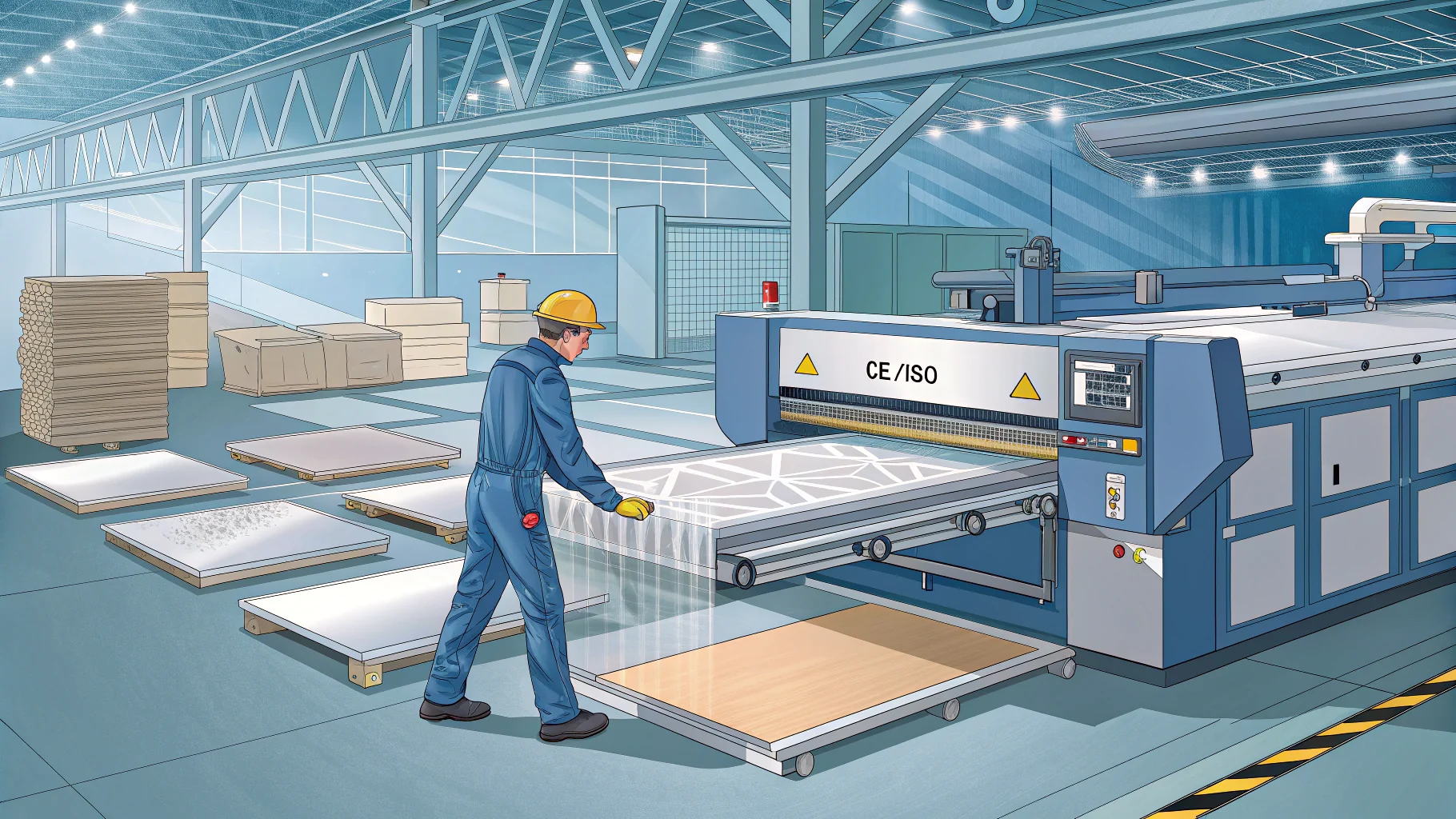

From my work at Suzhou Haoxinhe Electrical Equipment Co., Ltd., I know that PVC foam behaves differently from regular foam. Its density and structure require blade technologies that can handle both precision and heat control. Oscillating blades move rapidly back and forth, cutting cleanly without crushing the material. This makes them the most versatile choice for mixed production lines.

For high-volume jobs, carbide-tipped rotary blades excel. They rotate continuously and maintain a sharp edge even after long use, ensuring smooth, accurate cuts. When the application demands sealed edges — such as in insulation panels — hot wire blades can melt through PVC foam, leaving a smooth finish with minimal debris.

We integrate these blade options into our protective foam cutting machines, rotary bevel cutting machines, and different shapes cutting machines. By choosing the right blade for the density, thickness, and finish requirements, our clients achieve the cleanest results while minimizing waste.

Blade Technology Comparison for PVC Foam

| Blade Type | Strengths | Ideal Use Case |

|---|---|---|

| Oscillating Blade | Versatile, minimal compression, smooth edge | Mixed foam production, varied thicknesses |

| Carbide-Tipped Rotary Blade | Long life, continuous cutting, high precision | High-volume industrial production |

| Hot Wire Blade | Sealed edges, low debris, smooth finish | Insulation panels, precise sealed cuts |

I once helped a Canadian client replace their standard steel blades with carbide-tipped rotary blades in their PVC edge banding cutting machine. The result was a 30% increase in cutting speed and a significant drop in rework due to edge imperfections.

Conclusion

The cleanest PVC foam cuts come from matching blade technology to material needs, with oscillating blades giving the most versatile performance.

Insights:

Suzhou Haoxinhe Electrical Equipment Co., Ltd. produces high-performance PVC foam cutting solutions, including protective foam cutting machines, rotary bevel cutting machines, and PVC edge banding cutting machines. We combine oscillating, carbide-tipped rotary, and hot wire blade technologies to deliver clean, precise results for industrial clients in Europe, North America, and Asia. With five production lines and fully customizable options, we help manufacturers improve product quality, reduce waste, and boost efficiency in PVC foam processing.