What to Look for in a High-Performance Bubble Wrap Cutting Machine?

Not all bubble wrap cutters are created equal — and choosing the wrong one can slow down your production line.

A high-performance bubble wrap cutting machine combines speed, precision, durability, and smart automation to deliver fast, clean, and consistent protective packaging.

Here’s what you should look for before investing in one for your factory or warehouse.

Why does machine performance matter?

Packaging is often the last step before delivery — and if it lags, everything else backs up.

High-performance machines help manufacturers and logistics teams maintain flow, protect fragile items, and reduce waste — all while cutting labor needs.

Key Benefits of a High-Performance Model

- Up to 10,000+ cuts/day

- Consistent sheet lengths (±1mm accuracy)

- Fewer jams or misfeeds

- Reduced wrap waste (<5%)

- Seamless integration with conveyors or packing tables

If you’re shipping electronics, furniture, glassware, or medical gear, machine efficiency directly impacts your cost and reputation.

1. Precision and Cut Accuracy

Bubble wrap sheets that are too long waste material. Too short? Risk of damage.

Look for a machine with programmable digital controls and sensors that guarantee consistent cut lengths within ±1–2mm.

Features to Check

- Servo motor or encoder-based control

- Programmable interface with multiple presets

- Blade depth/pressure adjustment

- Cold and hot cutting options

- Automatic cut confirmation sensors

The more precise the cut, the less material you waste — and the faster your team packs.

2. Speed and Throughput

If you ship hundreds or thousands of products daily, speed matters.

Top machines deliver over 10,000 cuts/day — with adjustable speed settings to match your packing line’s pace.

Recommended Specs

| Production Level | Ideal Speed |

|---|---|

| Low (≤1000 cuts/day) | 2–3 cuts/min |

| Medium (2k–5k/day) | 5–7 cuts/min |

| High (5k–10k+/day) | 10–15 cuts/min |

Speed should not come at the cost of accuracy — high-performance cutters give you both.

3. Material Compatibility

Your bubble wrap may not be standard. Some factories use anti-static, recycled, foam-backed, or flame-resistant materials.

Choose a machine with adjustable tension, blade options, and roll holders that work across wrap grades and formats.

Materials Your Machine Should Support

| Material Type | Should Be Compatible? |

|---|---|

| Standard PE Bubble Wrap | ✅ |

| Anti-Static Pink Film | ✅ |

| Large-Cell Wrap | ✅ |

| Foam-Lined Film | ✅ |

| Recycled or Eco Wrap | ✅ |

If your wrap isn’t standard, confirm the machine’s blade type (cold, hot, perforated) can handle it without damaging the bubbles.

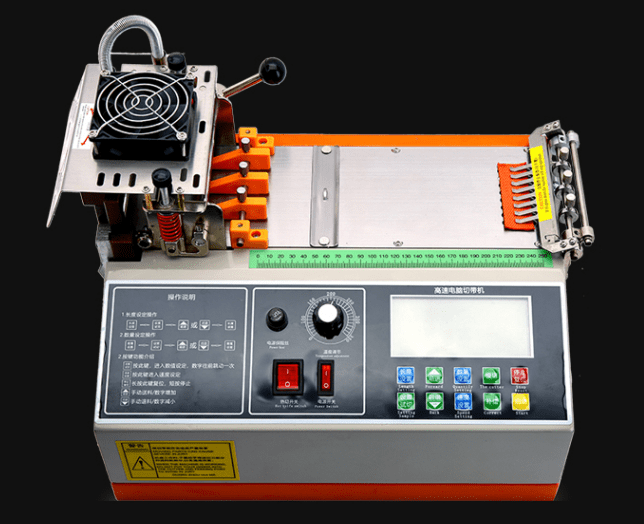

4. Programmability and Interface

A high-performance machine should be easy to control and adapt between jobs.

Look for a touchscreen interface with programmable memory — so operators can quickly switch between cut lengths and job types.

Ideal Interface Features

- Multi-language support

- Job memory and repeat batch settings

- Cut counter with reset function

- Emergency stop controls

- User lockouts for operator-level permissions

This keeps training simple and reduces the chance of manual errors.

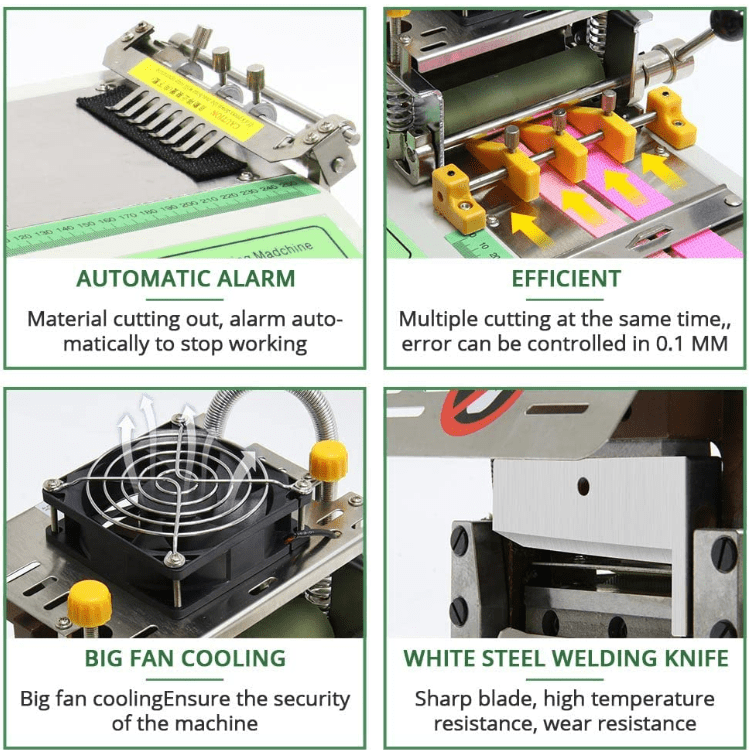

5. Durability and Maintenance

Packaging floors are tough — and machines must be tougher.

Choose a model with an industrial-grade frame, low-maintenance moving parts, and easy-to-replace components.

Build Quality Checklist

| Component | What to Look For |

|---|---|

| Frame | Welded steel or aluminum alloy |

| Motor | Heavy-duty with overload protection |

| Blade | Replaceable cold/hot/perforated |

| Feed Rollers | Anti-slip, anti-static, adjustable tension |

| Maintenance Access | Front or side panel for easy cleaning |

The longer it lasts, the better your return on investment.

6. Output Options and Integration

Your operation might need cut sheets stacked, rolled, or delivered directly to a packing table.

High-performance machines support multiple output options and can integrate into conveyors, lines, or station bins.

Output Configurations

- Roll-to-Sheet with Stacker

- Roll-to-Sheet with Manual Grab Tray

- Roll-to-Roll for large-scale rewinding

- Inline Conveyor Output

This makes the machine scalable — whether you’re packing on-demand or preparing materials in batches.

Why choose Suzhou Haoxinhe?

We don’t just sell machines — we build them to perform.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a CE- and ISO-certified factory with five production lines and years of experience in high-performance packaging solutions.

What Sets Our Machines Apart

- Cut accuracy: ±1mm repeatable

- Output: 10,000+ sheets/day

- Widths: Up to 1500mm

- Hot/cold/perforation cutting options

- Programmable interface with job memory

- 7–15 day global shipping

- Remote setup and training included

We also build:

- Velcro dot cutting machines

- Label, foam, and PVC sheet cutters

- Webbing ribbon and edge banding systems

Our clients include furniture exporters, electronics OEMs, medical kit assemblers, and global logistics warehouses.

Conclusion

Choosing a high-performance bubble wrap cutter isn’t about bells and whistles — it’s about speed, precision, and durability. Know what to look for, and your packaging line will thank you.

Insights

High-performance bubble wrap cutters deliver precise, high-speed, low-waste packaging prep. Suzhou Haoxinhe’s machines support programmable lengths, wide-format rolls, multiple materials, and smart automation — ideal for factories and fulfillment centers scaling protective packaging operations.