What Should You Consider When Selecting a Gauze Cutting Machine for Medical Textiles?

Producing medical gauze requires absolute precision and sterility – improper cuts can lead to product waste or even patient safety issues. Selecting the right cutting equipment is critical for maintaining quality standards while maximizing efficiency.

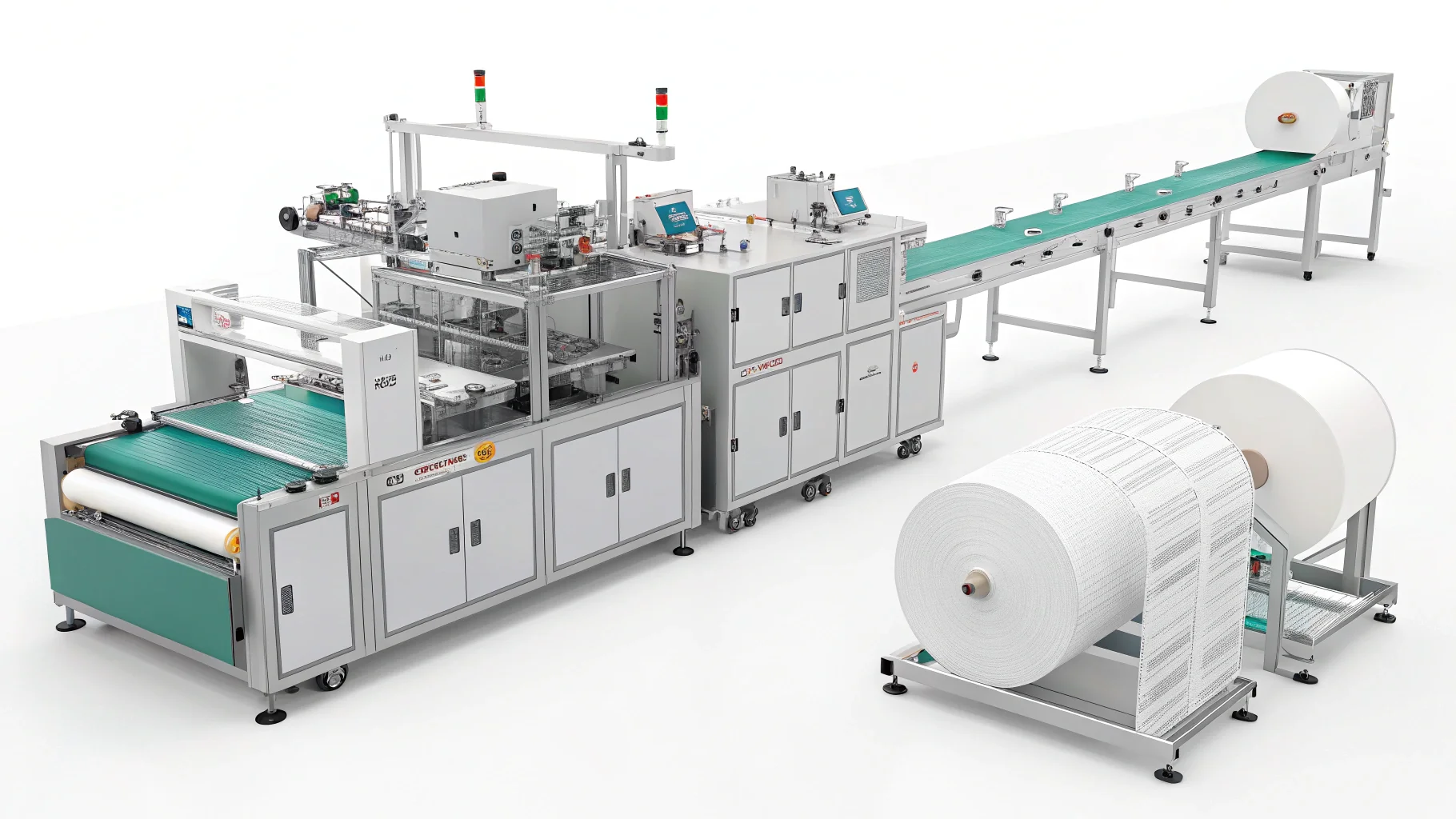

Modern gauze cutting machines combine sterile processing environments1 with precision blade technology2 to ensure clean, consistent cuts that meet medical standards. When selecting equipment, focus on sterile design features, precision cutting capabilities, and compliance with medical manufacturing regulations3.

How Do Modern Gauze Cutters Ensure Cleanliness and Precision?

Still struggling with frayed edges or contamination risks? Today’s advanced medical cutting systems4 address these challenges through innovative design and technology.

Modern gauze cutters maintain sterility through enclosed cutting chambers, antimicrobial surfaces, and lint-control systems while delivering precision through laser-guided alignment and tension-controlled feeding mechanisms.

Sterility Assurance Features

Sealed Cutting Environment

- Fully enclosed stainless steel cutting chamber

- Positive air pressure to prevent contaminant entry

- UV sterilization between production runs

Contamination Control

- HEPA filtration systems

- Automatic lint collection

- Antimicrobial surface coatings

- Clean-in-place (CIP) capability

Precision Cutting Technologies

| Advanced Cutting Methods | Technology | Benefit | Best For |

|---|---|---|---|

| Ultrasonic cutting | Seals edges while cutting | Non-woven gauze | |

| Laser cutting | Contactless sterile process | Precision shapes | |

| Rotary blade | High-speed continuous cutting | Rolled gauze | |

| Waterjet | Cold cutting, no thermal effect | Multi-layer gauze |

Precision Control Systems

- Laser positioning guides

- Digital length control (±0.5mm accuracy)

- Automatic tension adjustment

- Vision inspection systems

HAOXINHE Insights: Our medical textile clients report significant quality improvements after switching to our specialized cutting solutions. Our high-speed trademark cutting machine, modified for medical use, provides the perfect combination of speed and sterility for roll gauze production, while our computerized systems ensure absolute dimensional accuracy required for surgical dressings.

Material Compatibility

The machine must handle the specific types and thicknesses of medical gauze (e.g., woven, non-woven) you intend to produce, without snagging or damaging fibers.Production Capacity & Scalability

Choose a machine matched to your required throughput—high-speed models for large-scale operations, and compact units for smaller needs. Opt for scalable or modular systems if production demands may increase in the future.Cutting Precision & Quality

Machines should deliver uniform, precise cuts with minimal fraying to ensure the final product meets medical standards. Features such as automatic alignment, precise blade control, and customizable cut sizes/settings are crucial for maintaining consistent quality.Automation & Efficiency

Consider machines with advanced automation (e.g., folding, stacking, vibrating knife technology, CNC control, programmable patterns) to minimize manual labor, boost efficiency, and reduce operator errors.

Understanding sterile processing environments is crucial for ensuring safety and quality in medical textile production. ↩

Explore how precision blade technology enhances cutting accuracy and efficiency in medical applications. ↩

Learn about the essential regulations that ensure safety and quality in medical equipment manufacturing. ↩

Discover the latest advancements in medical cutting systems that enhance precision and sterility. ↩