What is the price range of a bubble wrap cutting machine1 in 2025?

Prices for industrial cutting machines fluctuate—but in 2025, they’re climbing fast due to global inflation, shipping volatility, and raw material shortages.

As of 2025, the price of a bubble wrap cutting machine1 ranges from $2,500 to $18,000 depending on automation level, cutting method2, and origin.

- 2025 Bubble Wrap Cutting Machine Price Range: From $2,500 to $18,000, based on automation, cutting method (blade or hot knife), and region of origin.

- China vs Europe3: China offers faster lead times and broader customization; Europe focuses on compliance, CE certification, and high-end components.

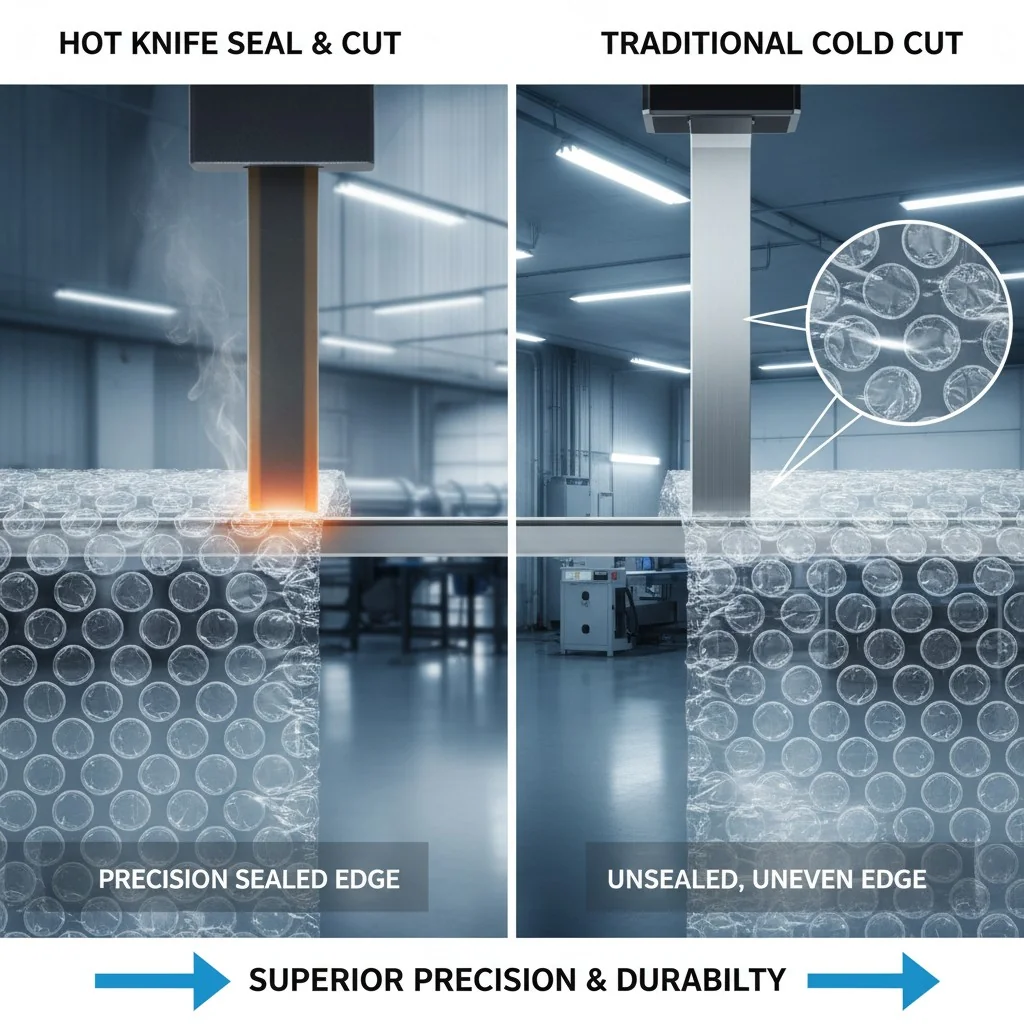

- Cutting Technologies: Hot knife models are ideal for sealing and precision, while blade cutters are better for budget applications.

- Price Influencers: PLC systems, safety certifications, and dual-mode cutting features can raise costs by $500–$2,500+.

- Smart Sourcing Tip: Don’t just chase low prices—optimize for function, durability, and post-sale support to maximize ROI.

If you’re trying to plan next year’s equipment budget, don’t just look at the machine cost. The real expense includes upgrades, certifications, and logistics. Let’s break it all down so you can avoid hidden surprises.

Cost breakdown: China vs Europe3 FOB pricing, blades/hot-knife, PLC options

Many first-time buyers think buying from China is only about price, but the functionality-to-price ratio is what really matters.

China offers more price tiers and customization, while Europe focuses on high-end, compliance-ready units.

Below is a breakdown of FOB pricing (Free On Board, excluding shipping) by region, cutting method, and system upgrades:

📊 2025 Bubble Wrap Cutting Machine Pricing Table

| Region | Cutting Method | Automation | PLC Control | Average FOB Price (USD) | Typical Lead Time | Notes |

|---|---|---|---|---|---|---|

| China 🇨🇳 | Blade | Manual | No | $2,500–$4,500 | 7–15 days | Basic model, no safety sensors |

| China 🇨🇳 | Hot Knife | Semi-Auto | Optional | $4,800–$7,500 | 10–20 days | Good for sealing edges |

| China 🇨🇳 | Hot Knife | Fully Auto | Yes | $7,800–$12,000 | 15–30 days | Customizable via touchscreen |

| Europe 🇪🇺 | Hot Knife | Fully Auto | Yes | $12,000–$18,000 | 30–45 days | CE-certified, more robust but less customizable |

| Europe 🇪🇺 | Blade | Manual | No | $4,500–$6,000 | 25–35 days | Often designed for lab use, not factory scale |

🔍 What increases the cost?

- PLC System (Programmable Logic Controller): Adds $800–$2,500 depending on complexity.

- Custom width/roll handling: Adds 10–15% on base machine price.

- Dual-mode cutting (hot+cold): Adds $1,000+.

- Safety certifications (CE, UL): May raise cost by $500–$1,500, especially in Europe.

🏭 How we price at Suzhou Haoxinhe Electrical Equipment Co., Ltd.

We offer both entry-level and high-performance models for industrial clients:

| Model Name | Cutting Method | Max Width | PLC Control | Price Range (USD) |

|---|---|---|---|---|

| HX-BW350 Basic Blade Cutter | Blade | 350mm | No | $2,800–$3,500 |

| HX-HK600 Semi-Auto Hot Knife | Hot Knife | 600mm | Optional | $5,200–$6,800 |

| HX-HK900 Pro with Touchscreen PLC | Hot Knife | 900mm | Yes | $8,500–$11,000 |

Our equipment is built in our Suzhou factory with 5 production lines, ensuring short lead time, OEM customization4, and on-site QC.

If you’re sourcing from platforms like Alibaba or visiting trade shows, watch for these warning signs:

- Fake CE Certificates

- No PLC brand name disclosure

- Unclear lead time5

- Plastic gear parts (wear out fast in 6 months)

⚖️ Final Comparison Summary

| Factor | China 🇨🇳 | Europe 🇪🇺 |

|---|---|---|

| Price Range | $2,500–$12,000 | $4,500–$18,000 |

| Lead Time | 7–30 days | 30–45 days |

| Certifications | Optional (can be added) | Mandatory (CE/UL standard) |

| Customization | High | Low |

| Support Language | Usually English + Chinese | English + Native |

| Repair Parts Supply | Fast (via Alibaba or direct) | Slower + expensive |

Conclusion

In 2025, buyers should expect to spend between $5,000 and $10,000 for a fully automatic, PLC-integrated bubble wrap cutting machine1 from China with reliable support and certification options.

🧠 Industry Insight: 2025 Pricing Trends for Bubble Wrap Cutting Machines

In 2025, we’re seeing a significant price polarization in the bubble wrap cutting machine1 market. The days of buying a $2,000 semi-auto cutter and expecting industrial performance are over. Inflation, labor shortages in parts manufacturing, and rising freight costs have pushed even mid-range machine prices up by 10–20% year-over-year.

But here’s the insider truth: China is still the best source for cost-to-performance machines, if you know what to look for. Many first-time buyers get burned because they chase the lowest price on Alibaba without verifying real specs—especially on the PLC brand and blade material. We’ve audited over 20 suppliers and found that sub-$4,000 machines often lack real hot-knife temperature regulation or come with plastic tension rollers—meaning downtime within 6 months.

The smarter approach is this: Budget $6,000–$9,000 for a fully automatic, PLC-based machine from China. This price bracket gives you access to touchscreen presets, CE-ready safety features, and solid steel feed rollers. Skip the $2,500 units unless you’re running fewer than 5k orders/month.

Tip from the field: Always ask your supplier to provide a video of a full-cut cycle and zoom in on the PLC screen—it tells you more than a spec sheet ever will.

As global pricing for industrial equipment rises in 2025, buyers looking for bubble wrap cutting machines should focus on value per function, not just base price. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers scalable options across manual and automatic models, with hot knife or blade systems, and PLC integration for industrial precision—at a competitive FOB price.

Explore this link to understand the pricing trends and features of bubble wrap cutting machines in 2025. ↩ ↩ ↩ ↩

Discover the various cutting methods available and how they influence machine performance and pricing. ↩

This resource will help you compare the advantages and disadvantages of sourcing from China versus Europe. ↩ ↩

Find out about the various customization options that can tailor machines to your specific needs. ↩

Understanding lead times can help you plan your equipment purchases and avoid delays. ↩