What is the best way to cut a gasket?

Gasket cutting feels simple—until you end up with uneven edges, poor seals, or wasted material.

The best way to cut a gasket is using a professional webbing tape cutting machine or die-cutting system that matches the gasket’s material, thickness, and required shape.

If you’ve been manually cutting gaskets or using basic tools, you might be wasting time, risking leaks, and increasing production costs. Let’s explore smarter options that offer clean, repeatable results.

What tools are most efficient for cutting gaskets?

[^1] tools, High-performance [gasket cutting](https://trianglefluid.com/common-gasket-cutting-processes-3-technologies-to-consider/)[^1] tools on table](https://hxcuttingmachine.com/wp-content/uploads/2025/04/1.jpg)

Scissors and knives often leave irregular edges and inconsistent shapes.

Industrial cutting machines1 like rotary bevel cutting machines1 or die-cut presses ensure precise, clean cuts across batches of gaskets with minimal waste.

When I first started working with overseas clients looking for gasket-cutting solutions, I quickly noticed that many were still stuck using hand-cutting methods or general-purpose die sets. That may work for small runs, but once volumes grow, it’s time to switch to specialized machines.

Key Machines for Gasket Cutting

| Machine Type | Best For | Materials Supported |

|---|---|---|

| Rotary Bevel Cutting Machine | High-speed, round gaskets | Rubber, cork, fiber |

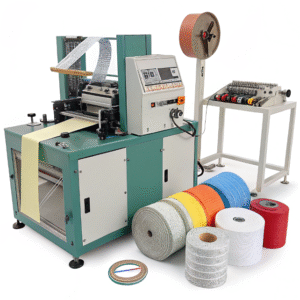

| Webbing Tape Cutting Machine | Sheet or strip gaskets | PVC, foam, plastic, textiles |

| Automatic Punching Cutting Machine | Custom gasket shapes | All gasket-grade sheet stock |

| Hot and Cold Cutting Machines | Temperature-sensitive sealing materials | Synthetic rubbers, plastics |

Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers all the above models with customizable options. We help match your gasket type and production scale with the ideal cutting equipment.

Things to Consider When Choosing a Cutting Method

- Material Type: Rubber gaskets behave very differently from foam or graphite.

- Volume: Are you cutting ten a day or ten thousand?

- Accuracy: Do you need millimeter precision?

- Edge Finish: Clean edges prevent leakage in sealing applications.

Choosing the wrong machine can cause misalignment, ragged edges, or worse—costly rework. That’s why so many clients from the HVAC and chemical industries trust our customizable webbing ribbon cutting machines.

Can you cut a gasket without a die?

[^1], Technician manually cutting a gasket by hand](https://hxcuttingmachine.com/wp-content/uploads/2025/04/6.jpg)

Cutting without a die might seem easier if you’re doing one-off jobs.

Yes, you can cut a gasket without a die by using precision digital cutters or computer tube cutting machines that follow programmed outlines.

Before I got into automation, I worked with a Canadian buyer who outsourced gasket production to low-cost suppliers. They were using outdated manual templates. As his orders scaled, the inconsistencies were costing him clients.

Alternative to Die Cutting

- Plotter Cutters: Great for prototypes and short runs.

- Computer-Controlled Tube Cutting Machines: Ideal for long narrow gaskets, especially with curves.

- Laser Cutters: Good for non-metallic materials like silicone or cork.

But here’s the catch: cutting without a die is slower, and setup time can eat into productivity. That’s why for anything beyond prototyping, I always recommend switching to automatic punching cutting machines1.

When Die Cutting Makes Sense

| Scenario | Die Cutting Advantage |

|---|---|

| High Volume Production | Fast, consistent, low unit cost |

| Complex Shapes | Clean edges and repeatability |

| Custom Orders | Tooling is worth the investment |

For clients like Mark Chen, who rebrands and resells in Canada, switching to programmable machines helped reduce rework and improve brand credibility.

What materials are hardest to cut accurately?

Some gasket materials just don’t play nice—foams compress, rubbers stretch, and composites chip.

Thick rubber sheets, multi-layer composites, and soft foams are the most difficult materials to cut without deforming or fraying the edges.

One of the challenges our customers face is matching the material with the right cutting process. For example, a Bubble wrap cutting machine won’t handle thick neoprene rubber well. That’s why we help customers test samples before finalizing machine specs.

Common Problem Materials

| Material | Problem | Recommended Machine |

|---|---|---|

| Foam | Compresses during cutting | Protective Foam Cutting Machine |

| Rubber | Tends to stretch or drag | Hot and Cold Cutting Machine |

| Fiberglass Composites | Frays at edges | Rotary Bevel Cutting Machine |

Why Accuracy Matters

Poor cuts reduce the sealing efficiency of gaskets. That can lead to:

- Product recalls

- Leaks and contamination

- Reduced equipment lifespan

With Suzhou Haoxinhe’s customizable cutting machines, clients can adjust blade speed, temperature, and pressure based on the material properties.

I remember one case where a client in the pharmaceutical industry had leaks due to jagged gasket edges. Switching to our high-speed trademark cutting machine not only fixed the problem—it also improved their production time by 40%.

Conclusion

The best gasket cutting2 method depends on your material, volume, and accuracy needs—but using the right machine changes everything.

INSIGHT:

To cut a gasket efficiently and precisely, use an industrial-grade machine that matches your material and shape requirements. Suzhou Haoxinhe offers customizable cutting machines such as rotary bevel, hot and cold, and webbing tape cutters to meet diverse gasket production needs across industries.