What is the best rubber gasket cutting machine1?

Rubber is tough, stretchy, and essential for sealing—but it’s also one of the hardest materials to cut cleanly without deforming or wasting material.

The best rubber gasket cutting machine1 is a rotary bevel cutting machine or automatic punching cutting machine2 with cold-knife technology and programmable settings for thickness and speed.

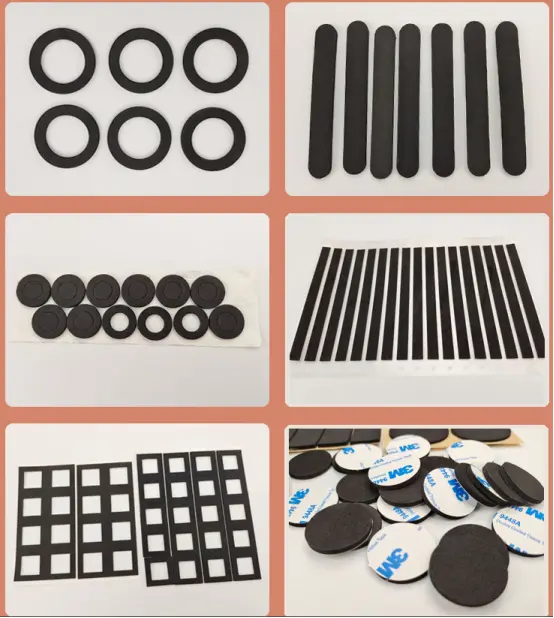

Rubber gaskets are used in everything from plumbing to automotive, yet many manufacturers still cut them by hand or with outdated tools. That leads to waste, poor fit, and unhappy clients. Here’s how to fix that.

Why is rubber difficult to cut accurately?

Rubber’s elasticity makes it great for sealing—but also makes it bounce, stretch, and tear during cutting.

Rubber is difficult to cut because it stretches under blade pressure, causing inaccurate dimensions, jagged edges, and wasted material.

A client in Germany once told me, “Cutting rubber by hand takes three times longer, and our rejection rate is over 20%.” After switching to our rotary bevel cutting machine, that number dropped below 2%.

Common Rubber Cutting Problems

| Problem | Cause | Result |

|---|---|---|

| Stretching | Too much pressure or dull blade | Gasket loses shape |

| Tearing | Incorrect blade angle | Edges are jagged or unusable |

| Warping | Heat-based methods | Material loses elasticity |

| Inconsistent Thickness | Uneven feed or pressure | Leaks and fitment issues |

That’s why a cold-cutting, pressure-controlled machine is a must for rubber.

What machine works best for rubber gasket production?

Rubber comes in sheets, rolls, and various densities—so your machine must handle flexibility and pressure evenly.

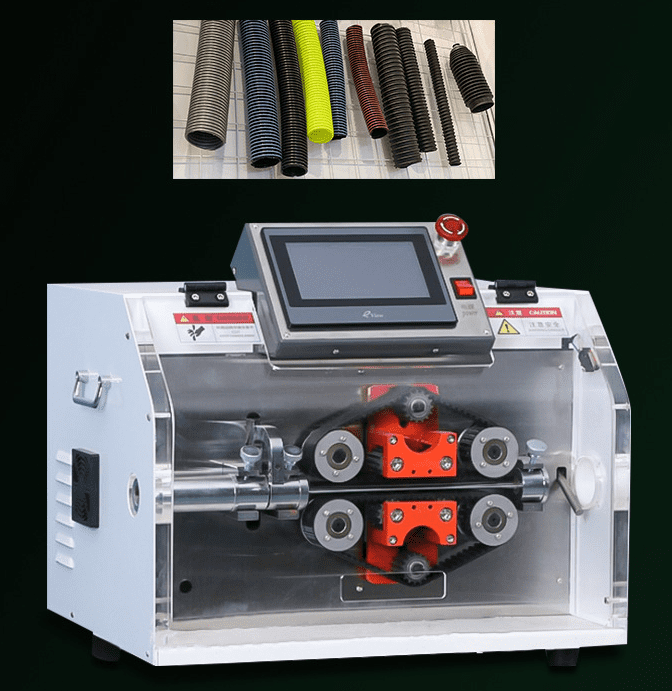

The best machines for rubber gasket cutting are rotary bevel cutting machines, webbing ribbon cutting machines, and automatic punching cutting machine2s designed to manage stretchable and thick materials.

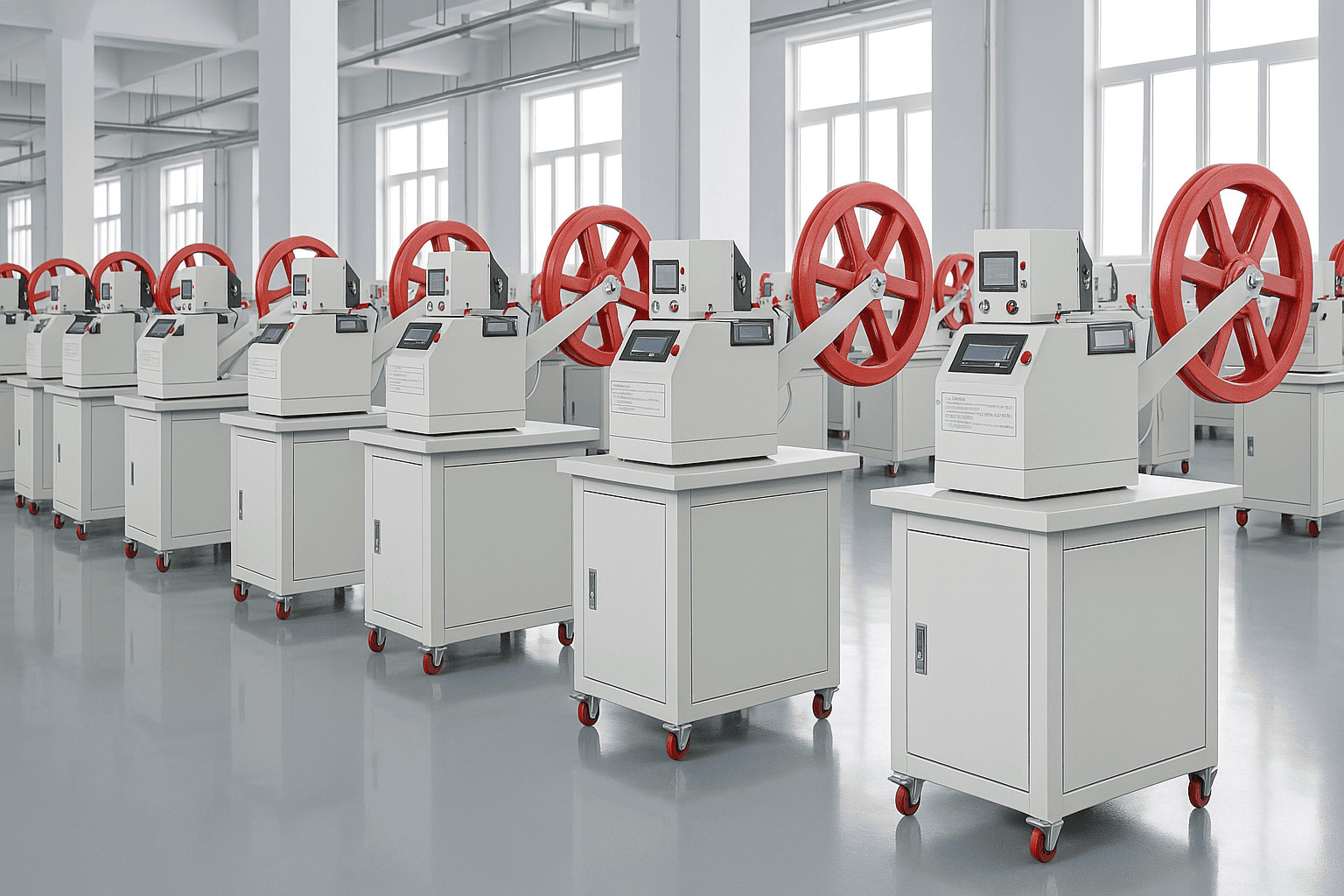

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we’ve engineered machines that cut rubber accurately without tearing, using cold-blade technology3 and anti-slip rollers for smooth feeding.

Recommended Machines for Rubber

| Machine | Ideal For | Rubber Thickness |

|---|---|---|

| Rotary Bevel Cutting Machine | Circular and rounded gaskets | 1mm to 10mm |

| Webbing Tape Cutting Machine | Long narrow rubber gaskets | 0.5mm to 6mm |

| Automatic Punching Cutting Machine | Mass production | Up to 12mm |

| Computer Tube Cutting Machine | Tubular rubber components | 1mm to 5mm |

Each machine can be customized with blade types and speed settings depending on your material and gasket design.

How to avoid stretching and deformation in rubber cutting?

You can have the best blade in the world, but if your feed system pulls the rubber too hard—it still stretches.

To avoid rubber stretching or deformation, use cold blades, slow feed rates, and support the material with vacuum or pressure rollers.

One of our HVAC clients in Canada used a fast-feed machine originally made for foam. It worked fine—until they switched to EPDM rubber. That’s when the gaskets started missing their spec. We replaced it with a webbing tape cutting machine with anti-slip rollers, and their tolerances tightened up instantly.

Best Practices for Cutting Rubber Gaskets

- Use cold blades: Heat can harden or warp rubber

- Adjust pressure: Soft rubbers require less force

- Slow down the feed rate: Reduces stretching

- Pre-test cuts: Always run a trial before full batches

- Replace blades often: Rubber dulls edges faster than foam or PVC

Blade and Feed Settings

| Rubber Type | Blade Type | Feed Speed | Pressure |

|---|---|---|---|

| Natural Rubber | Straight cold knife | Medium | Low |

| EPDM | Rotary beveled blade | Slow | Medium |

| Silicone Rubber | Ceramic edge blade | Slow | Low |

| Nitrile (NBR) | Punching die | High | High |

Our cutting machines are programmable, so once you dial in the best settings, your team can repeat it with every batch.

What industries use rubber gaskets, and what are their needs?

Rubber gaskets are everywhere: from sealing water pipes to isolating electric currents in industrial machines.

Rubber gaskets are used in automotive, plumbing, HVAC, electrical, and manufacturing industries—and each demands consistent quality and tight dimensional tolerances.

One of our European clients switched from imported gaskets to in-house cutting with our automatic punching cutting machine2. He saved 30% on costs, reduced shipping delays, and gained complete control over specs.

Industry Applications

| Industry | Application | Recommended Machine |

|---|---|---|

| Automotive | Engine and transmission seals | Rotary bevel cutting machine |

| Plumbing | Pipe flange gaskets | Webbing tape cutting machine |

| Manufacturing | Sealing machine covers | Automatic punching machine |

| Electronics | Insulating gaskets | Computer tube cutting machine |

| HVAC | Air duct and filter seals | Webbing ribbon cutting machine |

We design our machines to suit the material and application so that customers like Mark Chen—who buys in bulk and resells in North America—can guarantee performance and consistency.

Conclusion

Rubber gasket cutting needs machines that balance pressure, speed, and precision—like those built by Suzhou Haoxinhe.

INSIGHT:

The best way to cut rubber gaskets is with rotary bevel or webbing tape cutting machines equipped with cold-blade and anti-stretch technology. Suzhou Haoxinhe’s customizable cutting solutions ensure clean, accurate, and high-speed production of rubber gaskets for all major industries.

Explore this link to discover top-rated rubber gasket cutting machines that enhance precision and efficiency in production. ↩ ↩

Find out how automatic punching cutting machines can streamline production and improve accuracy in rubber gasket manufacturing. ↩ ↩ ↩

Learn about cold-blade technology and its benefits for cutting rubber, ensuring clean edges and reduced waste. ↩