What is the best PVC gasket cutting machine?

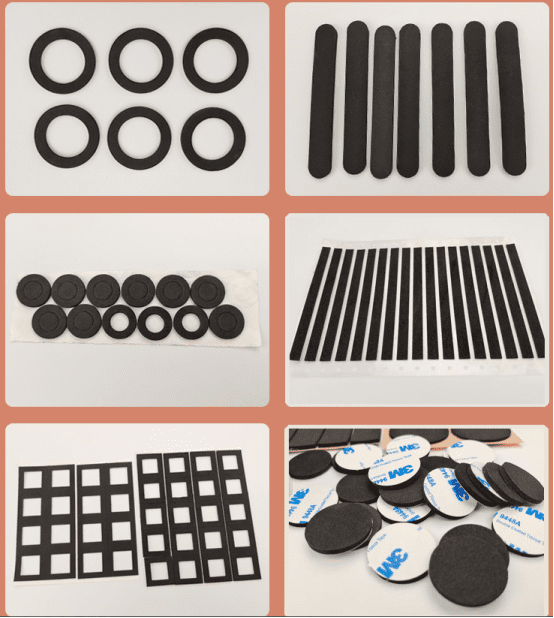

PVC is flexible, durable, and widely used—but cutting it into precise gasket shapes can be a challenge with traditional tools.

The best PVC gasket cutting machine is a cold-blade webbing tape cutting machine or a computer-controlled flatbed cutter that prevents deformation and ensures precision without melting the material.

If you’ve been struggling with warped edges or inconsistent cuts on PVC sheets, you’re not alone. Let’s explore the right tools and techniques to handle PVC gaskets with accuracy and efficiency.

Why is PVC difficult to cut with basic tools?

PVC seems easy to work with—until your gaskets start showing burn marks, jagged edges, or shrink during cutting.

PVC is tricky to cut because it melts under high temperatures and deforms if not properly supported during the process.

One of my clients from the HVAC industry in France once used heated blades to speed up cutting. The result? Edges curled, gaskets didn’t fit, and the sealing was compromised. They switched to a cold-cutting PVC edge banding cutting machine from our factory, and their reject rate dropped to nearly zero.

What Makes PVC Cutting Tricky?

| Problem | Cause | Impact |

|---|---|---|

| Warping | Too much heat or pressure | Gasket won’t seal properly |

| Chipping | Dull or unsuitable blade | Inconsistent shape |

| Melting | Friction-based tools | Material damage and fumes |

That’s why a precise, cold-cutting method is essential for PVC.

What machine is best for cutting PVC gaskets?

Cutting PVC gaskets at scale requires more than just a sharp blade—it needs speed, accuracy, and control.

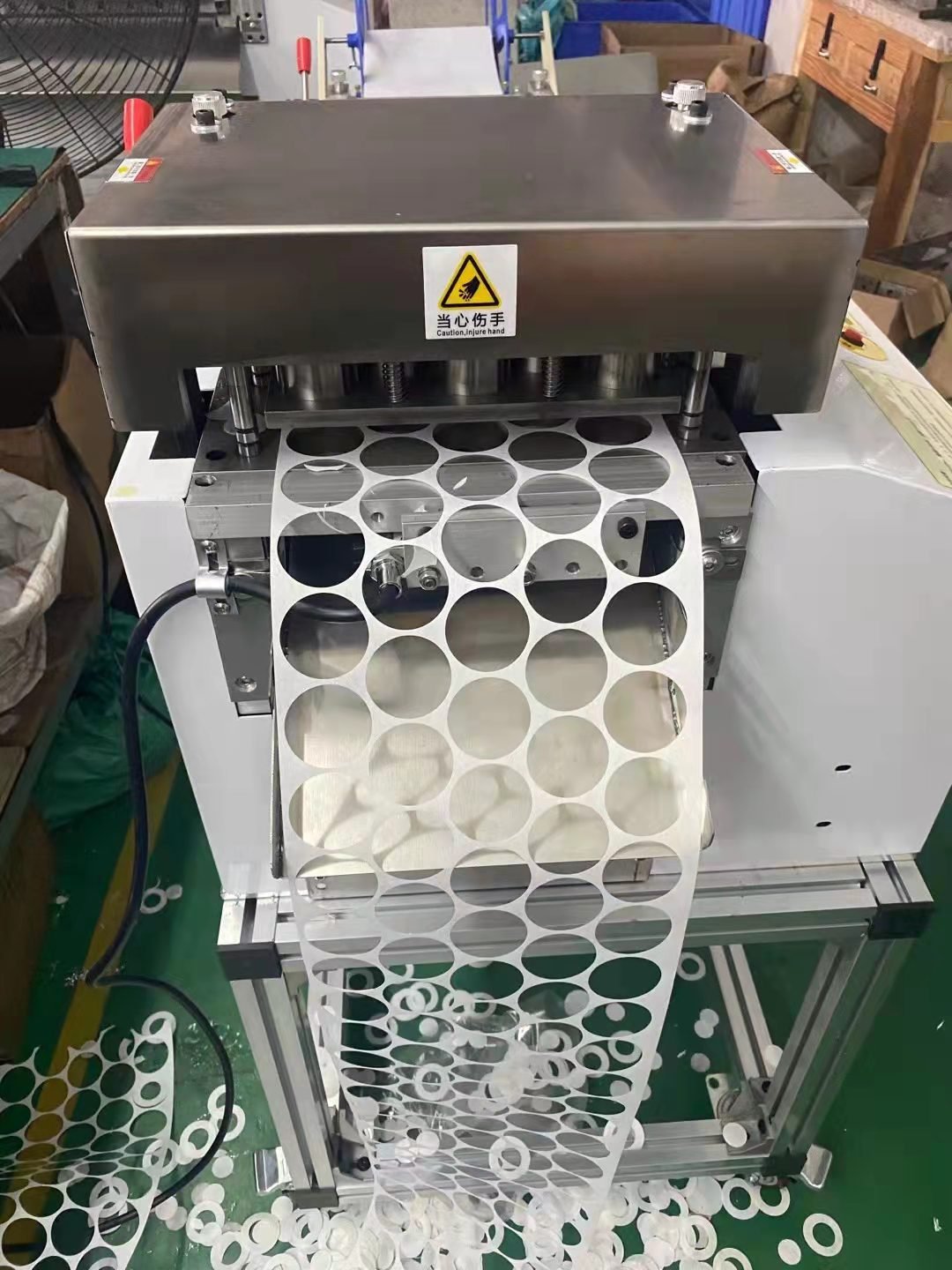

The best machines for PVC gasket cutting are cold-cut webbing tape cutting machines and computer tube cutting machines that offer adjustable speed and pressure.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our PVC edge banding cutting machine is specially built for soft plastic-based gasket materials like PVC. It uses a sharp, fast-moving cold blade to produce clean, burr-free cuts.

Recommended Machines

| Machine | Ideal For | Features |

|---|---|---|

| PVC Edge Banding Cutting Machine | Sheet or roll PVC | Cold blade, high precision |

| Webbing Tape Cutting Machine | Long strip gaskets | Adjustable feed length |

| Computer Tube Cutting Machine | Flexible PVC tube gaskets | Software-controlled cuts |

| Automatic Punching Cutting Machine | Repetitive gasket shapes | Ideal for batch production |

We’ve shipped these machines to clients in Europe, Southeast Asia, and North America who need reliable and scalable gasket production.

How to prevent PVC from deforming during cutting?

Even with the right machine, incorrect settings can still ruin your PVC gaskets.

To prevent PVC deformation, use a cold blade, maintain low pressure, and stabilize the material with anti-slip rollers or vacuum tables.

I remember a case from a Canadian client who used fast feeding but high blade pressure. The result? The PVC stretched, and the gasket dimensions were off by millimeters. Once we adjusted the speed and pressure settings on their automatic webbing tape cutting machine, the problem was solved instantly.

Best Practices for Cutting PVC Gaskets

- Keep blade sharp: Replace blades regularly to reduce friction.

- Avoid heat: No laser or hot knives—these melt PVC.

- Use stabilization tools: Anti-slip rollers and vacuum tables prevent movement.

- Slow and steady: Let the blade do the work—avoid forcing the cut.

Our machines offer all of these options and allow real-time adjustments to avoid material waste.

Maintenance Tips

| Action | Frequency | Why It Matters |

|---|---|---|

| Blade sharpening/replacement | Every 50–100 hours | Keeps cuts clean |

| Pressure calibration | Monthly | Prevents compression or tearing |

| Feeding roller cleaning | Weekly | Maintains grip on slippery PVC |

Which industries need PVC gasket cutting machines?

PVC gaskets are used everywhere—from ventilation ducts to chemical containers.

Industries such as HVAC, electrical insulation, chemical packaging, and plumbing all rely on PVC gaskets—and benefit from high-precision cutting machines.

One buyer in Italy came to us looking to replace imported gaskets. By bringing production in-house with our webbing ribbon cutting machine, he reduced costs by 40% and sped up delivery.

Industry Use Cases

| Industry | PVC Gasket Application | Suggested Machine |

|---|---|---|

| HVAC | Pipe joints, duct seals | PVC edge banding cutting machine |

| Plumbing | Water-tight seals | Webbing tape cutting machine |

| Electrical | Insulation layers | Computer tube cutting machine |

| Packaging | Seals for boxes and drums | Protective foam cutting machine |

We understand that clients like Mark Chen want machines that are customizable, efficient, and compatible with North American standards—and that’s exactly what Suzhou Haoxinhe provides.

Conclusion

PVC gasket cutting is simple when you have the right cold-cutting machine with controlled speed and pressure—like those from Suzhou Haoxinhe.

INSIGHT:

To cut PVC gaskets cleanly and efficiently, use a cold-blade machine such as Suzhou Haoxinhe’s PVC edge banding cutting machine or webbing tape cutting machine. These tools offer precision, prevent material deformation, and ensure quality results for industrial gasket production.