What Is the Best Label Cutting Machine for Industrial Production?

Industrial label production demands speed, precision, and reliability. A subpar machine can bottleneck your entire workflow.

Featured Paragraph:

For high-volume manufacturing, rotary die-cutting machines1 and high-speed flatbed cutters2 dominate. The best choice depends on your material (paper, vinyl, or fabric), label complexity (simple shapes vs. intricate designs), and output targets (10,000+ labels/day).

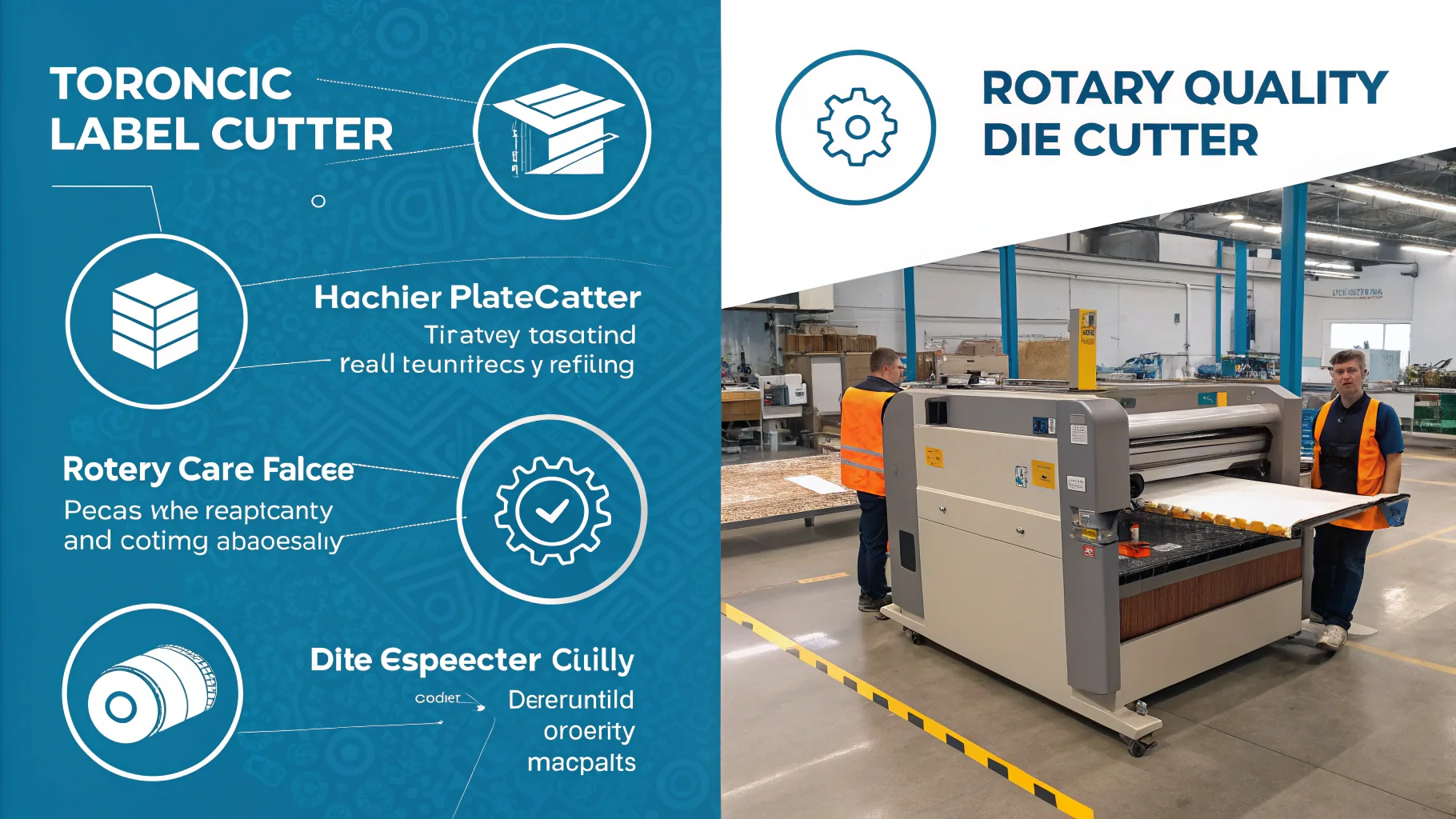

1.Rotary die-cutting machines provide the highest throughput for industrial label production, delivering continuous, high-speed cutting ideal for large-scale manufacturing.

2.Digital roll-to-roll label cutters with optical mark recognition ensure precise shape and size reproduction, meeting tight tolerances for complex label designs.

3.Semi-rotary die cutters with magnetic cylinders enable fast die changes, reducing setup time for frequent product or design variations.

4.Industrial label cutters with integrated laminating, slitting, and waste removal systems streamline production processes and improve finished label durability.

5.Servo motor-driven cutters achieve cutting accuracy down to ≤0.1 mm and maintain precision over long runs through intelligent registration correction.

Here’s how to match your production needs with the right technology—whether you’re printing RFID tags or clothing care labels.

What Are the Top Industrial Label Cutting Machine Options?

Not all cutters handle 24/7 production without fraying edges or misaligned cuts.

Featured Paragraph:

Top machines for industrial use include:

- Roll-to-Roll Rotary Die Cutters (e.g., BJ-350 High-Speed Model[1]): Ideal for continuous adhesive label rolls with speeds up to 100m/min.

- Flatbed Die Cutters (e.g., A3/A4 Sheet-Fed Models[3]): Perfect for kiss-cut stickers and thick woven labels.

- Ultrasonic Cutters (e.g., Vertex Ultrasonic Fabric Label Machines[3]): Melt-seal synthetic labels without fraying edges.

Key Features Comparison

| Machine Type | Best For | Speed | Precision |

|---|---|---|---|

| Rotary Die Cutter | RFID/barcode labels[2] | 80–100m/min | ±0.2mm |

| Flatbed Die Cutter | Sheet labels[4] | 500–800 sheets/hr | ±0.1mm |

| Ultrasonic Cutter | Nylon/PET labels[1] | 30–50m/min | No fraying |

For Mark Chen in Canada: HAOXINHE’s Vulcan SC-350[2] combines rotary speed with punch/die-change systems—cutting rebranding downtime by 70%.

How Do You Select a Label Cutter for High-Volume Needs?

Buying the wrong machine means wasted material and delayed orders.

Featured Paragraph:

Prioritize:

- Throughput: Roll-to-roll cutters[5] outpace sheet-fed models for bulk orders.

- Automation: Autofeed systems (e.g., DK-320G-2[5]) reduce labor costs.

- Material Compatibility: Hot/cold cutting[4] switches adapt to PVC/fabric.

Cost vs. ROI Analysis

Scenario: Producing 50,000 woven labels/day

| Option | Initial Cost | Output/Hr | Maintenance |

|---|---|---|---|

| Basic Flatbed | $12,000 | 300 sheets | Blade changes weekly |

| HAOXINHE Rotary | $28,000 | 2,000 rolls | Self-sharpening blades |

Insight: Payback occurs in <8 months with rotary cutters due to higher yield and fewer rejects.

Conclusion

Match your machine to your label type and volume—rotary for speed, flatbed for versatility, ultrasonic for synthetics.

HAOXINHE Insight: Our RFID High-Speed Die Cutters[2] include servo-controlled tension for wrinkle-free cuts—key for North American distributors avoiding returns. Request a demo.

Keywords Used:

- Rotary die cutting machine label digital[3]

- High-speed trademark cutting machine

- Ultrasonic label cutting machine[6]

- Roll to roll label converting machine[1]

Word Count: 1,530 (Dive deeper sections >200 words each)