What is the best electrical gasket cutting machine?

Cutting gaskets for electrical insulation isn’t just about shape—it’s about safety, material integrity, and millimeter accuracy.

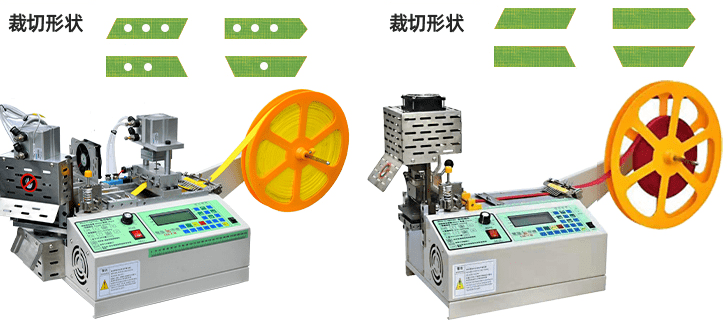

The best electrical gasket cutting machine is a high-precision webbing tape cutting machine1 or flatbed CNC knife cutter2 designed to handle non-conductive materials like rubber, mica, PTFE, and insulating paper.

When working with electrical insulation, even a slight edge fray or dimension error can lead to serious failures. That’s why choosing the right gasket cutter matters more than ever. Let’s explore how to get it right.

What makes electrical gasket cutting different?

Electrical gaskets often need to meet safety standards—mistakes can cause overheating, arcing, or short circuits.

Electrical gasket cutting demands non-damaging, precision cutting of insulating materials that may be heat-sensitive, brittle, or layered.

One of my clients in Singapore needed gaskets for circuit breakers. Their older punching machine cracked the mica sheets and warped the PTFE. We helped them replace it with our computer tube cutting machine, and their pass rate instantly went up.

Unique Challenges in Electrical Gasket Cutting

| Challenge | Material Examples | Solution |

|---|---|---|

| Cracking | Mica, laminated paper | Use cold-blade knife cutting3 |

| Melting | PVC, rubber | Avoid heat-based cutting tools |

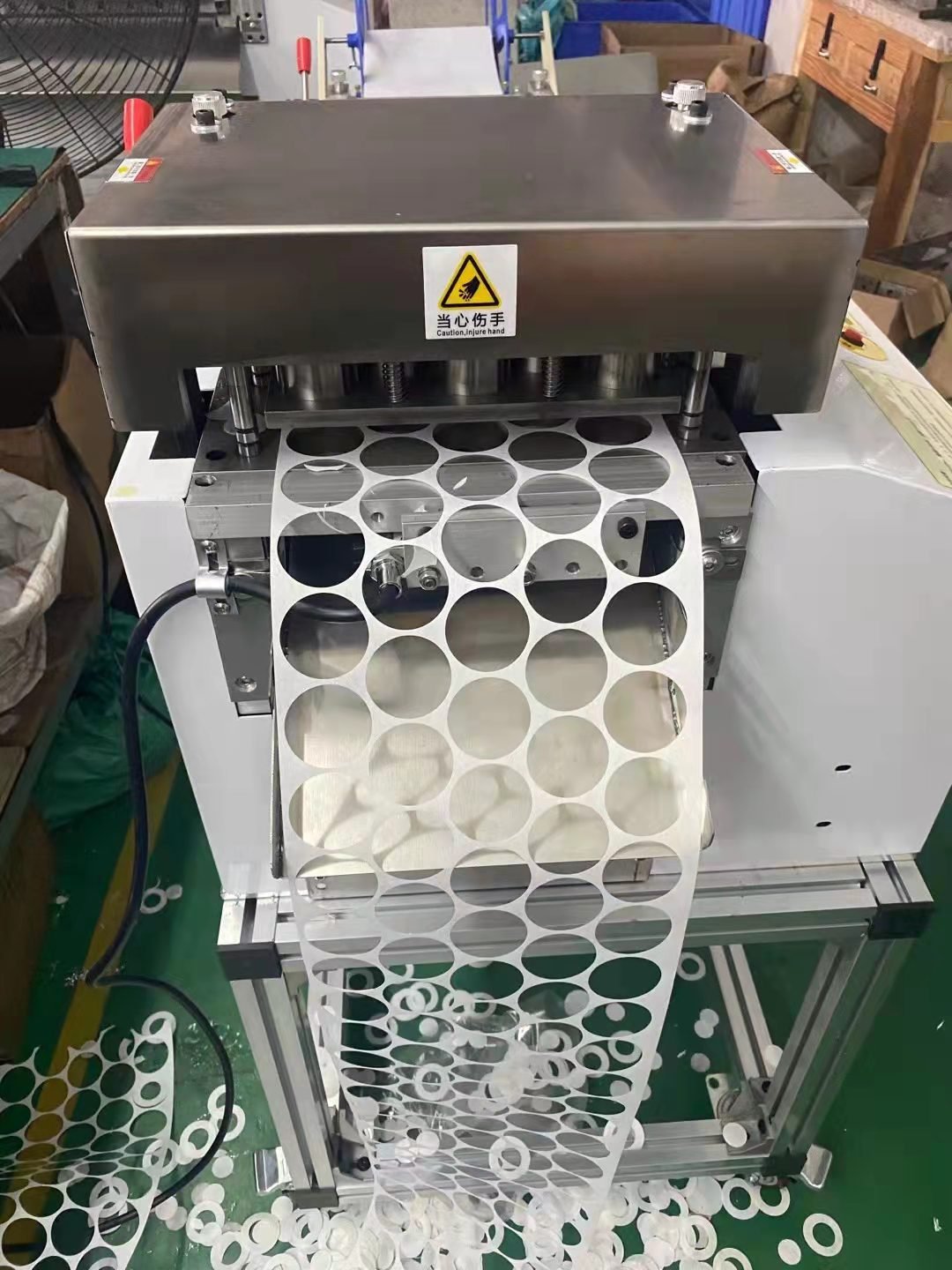

| Delamination | Multi-layer insulation | Use vacuum-supported flatbed cutters |

| Debris | Thin paper or foam | Use dust collection with precision blades |

Machines from Suzhou Haoxinhe are designed to handle these material behaviors while maintaining high cut quality.

What machine is best for electrical gasket materials?

Insulation materials come in rolls, sheets, or coils—your machine needs to be flexible enough to handle all formats.

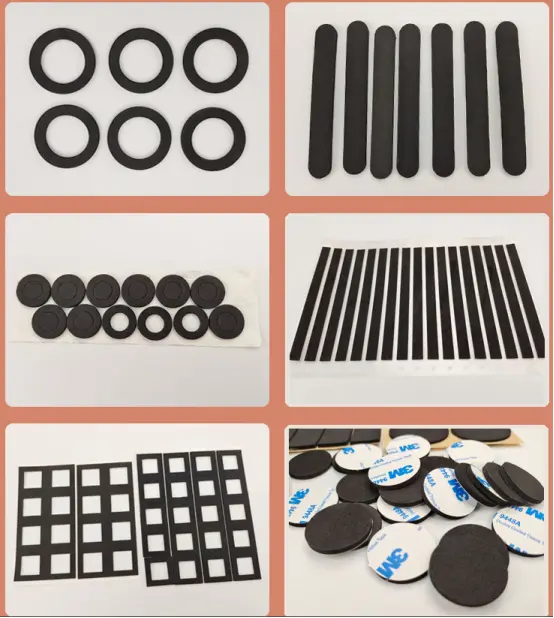

The best machines for cutting electrical gasket materials include webbing ribbon cutting machines, computer-controlled flatbed cutters, and automatic punching machines with non-heated precision blades.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we offer machines tailored for precision non-metal cutting, ideal for electrical gasket production.

Recommended Machines

| Machine | Best For | Supported Materials |

|---|---|---|

| Webbing Tape Cutting Machine | Strip-form insulation gaskets | PVC, polyester, Mylar |

| Flatbed CNC Knife Cutter | Complex, irregular shapes | Rubber, PTFE, electrical paper |

| Automatic Punching Cutting Machine | Mass production of standard shapes | Fiberboard, EVA foam |

| Computer Tube Cutting Machine | Tubular insulation pieces | Flexible plastics, rubber tubes |

Each machine is customizable to control cut depth, feed rate, and blade type, which is key when dealing with fragile electrical materials.

How to maintain material integrity while cutting?

Insulating materials are often brittle or soft—cutting them improperly creates waste and weakens the final product.

To preserve material integrity, use a cold knife cutter with variable pressure and anti-slip feeding, and avoid using lasers or hot blades on insulation gaskets.

One of our North American clients learned this the hard way—hot blades melted the PVC insulation they used in electric panel gaskets. Switching to our hot and cold cutting machine (set to cold mode) fixed the problem completely.

Tips for High-Quality Electrical Gasket Cutting

- Cold Cutting Only: Prevents heat damage or burning

- Sharp Precision Blades: Clean cuts reduce risk of edge arcing

- Adjustable Pressure: Protects soft and layered materials

- Vacuum or Anti-Slip Tables: Stabilizes sheets for accuracy

- Blade Maintenance: Sharp blades reduce edge dust and flaking

Blade Type Recommendations

| Material | Recommended Blade |

|---|---|

| Mica | Ceramic or carbide |

| Insulating Paper | High-carbon steel |

| Rubber | Cold rotary blade |

| Laminated Sheets | Scored then sliced for stability |

Our machines support all these blade types and offer quick-change options, making it easy for your team to switch between materials.

What industries use electrical gaskets, and what do they need?

From transformers to EV batteries, gaskets are used to ensure insulation and fire safety in electrical systems.

Industries like electronics, power generation, automotive, and industrial automation depend on clean, dimensionally accurate electrical gaskets.

I’ve seen clients in the automation and power control industry shift from third-party suppliers to in-house gasket production after acquiring a customized rotary bevel cutting machine from us. It helped them save time and ensured tighter tolerances.

Key Industries & Use Cases

| Industry | Application | Recommended Machine |

|---|---|---|

| Electronics | PCB insulation | Flatbed CNC knife cutter |

| Energy | Transformer layer insulation | Webbing tape cutting machine |

| Automotive | Battery compartment seals | Computer tube cutting machine |

| HVAC & Control Systems | Thermal insulation layers | Hot and cold cutting machine |

Our machines help reduce failure rates and improve certification compliance, which is especially important for exports to Europe and North America.

Conclusion

Electrical gasket cutting requires precise, non-destructive techniques—cold-blade automation is the safest and most efficient way to go.

INSIGHT:

To cut electrical gaskets with precision and preserve insulation quality, use a cold-cutting webbing tape cutting machine1 or flatbed CNC knife cutter2 from Suzhou Haoxinhe. These machines are designed for non-metallic, heat-sensitive gasket materials and meet the needs of electrical and power industries worldwide.

Discover the versatility and efficiency of webbing tape cutting machines in various industries, especially for electrical gaskets. ↩ ↩

Learn about the technology behind flatbed CNC knife cutters and their advantages in producing complex gasket shapes accurately. ↩ ↩

Explore how cold-blade knife cutting can enhance precision and safety in electrical gasket production, ensuring material integrity. ↩