What is the best automatic gasket cutting machine?

Manually cutting gaskets slows production, causes material waste, and leads to inconsistent quality. That’s a big problem in precision industries.

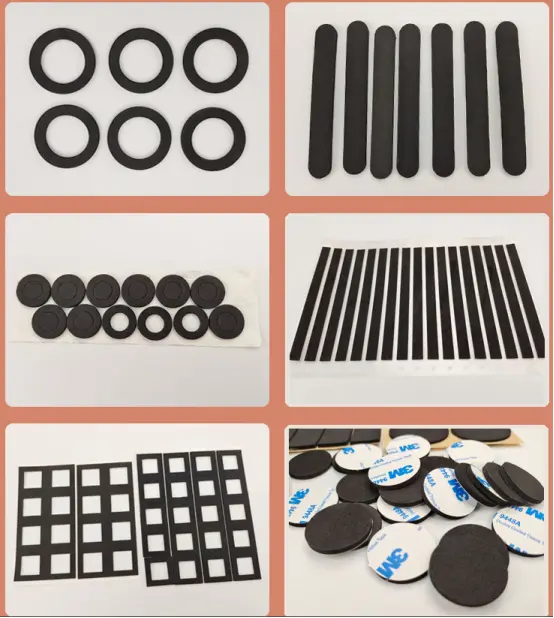

The best automatic gasket cutting machines1 are CNC flatbed cutters2, webbing ribbon cutting machines, and automatic punching cutting machines with customizable tooling and digital control systems.

If you’re producing gaskets at scale—whether from PTFE, rubber, foam, or paper—automation isn’t just a luxury. It’s a necessity. Let’s look at how automatic machines streamline gasket production across industries.

What types of automatic gasket cutting machines1 are available?

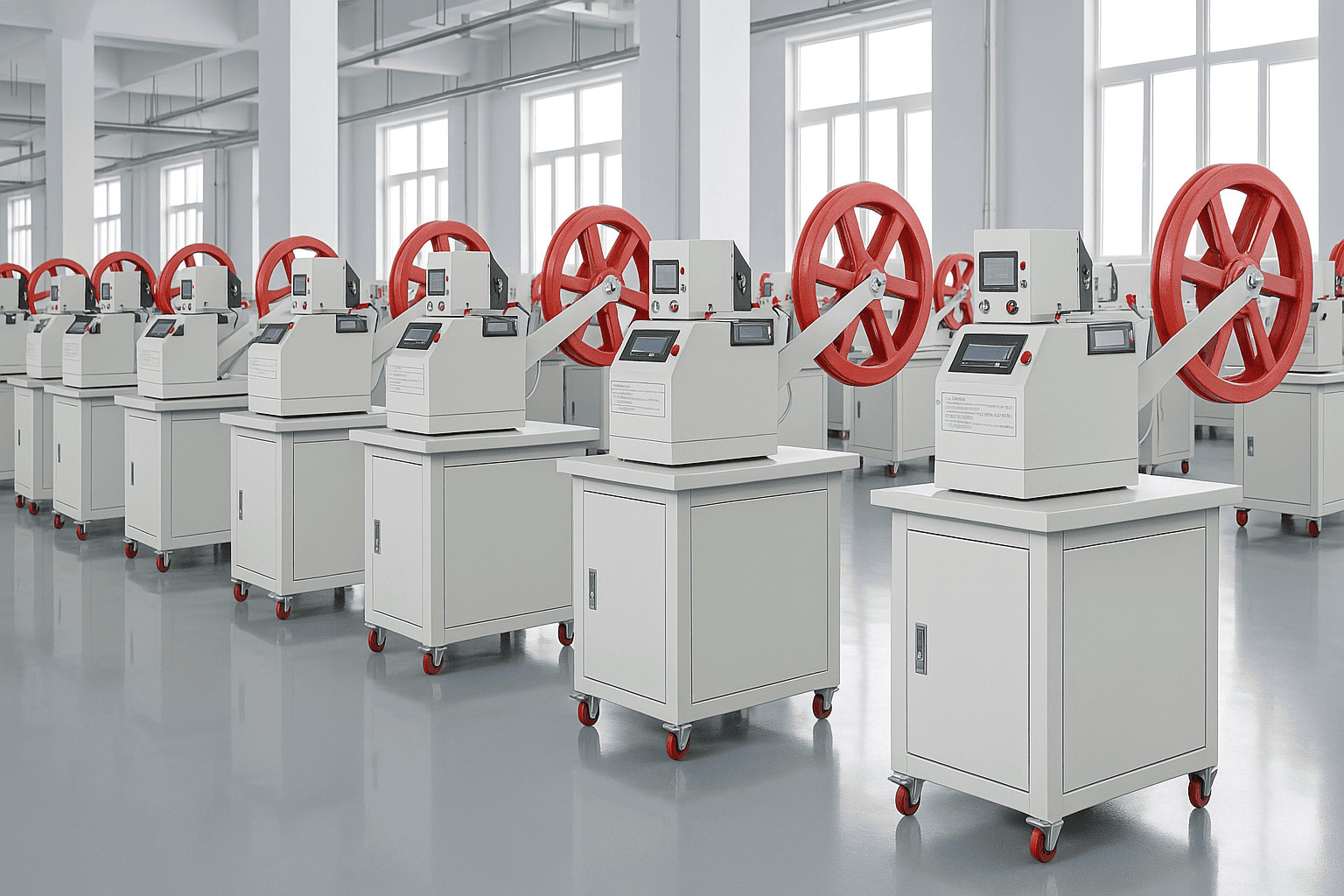

[^1], Multiple gasket cutting machines lined up](https://hxcuttingmachine.com/wp-content/uploads/2025/04/1.jpg)

Gasket materials vary, and so do the machines that cut them. One type doesn’t fit all.

There are several types of automatic gasket cutting machines1, including flatbed CNC cutters, rotary bevel cutters, webbing tape cutting machines3, and automatic punching systems. Each is suited to different materials and production scales.

I’ve worked with clients in North America who cut PTFE for chemical applications, and others in Europe handling foam and rubber for HVAC systems. The machine you choose will depend on your gasket’s material, thickness, and design.

Common Machine Types

| Machine | Best for | Material Type |

|---|---|---|

| Flatbed CNC Knife Cutter | Custom shapes | PTFE, rubber, fiber |

| Webbing Tape Cutting Machine | Long narrow gaskets | Foam, PVC, plastic |

| Automatic Punching Cutting Machine | High-volume, simple shapes | Cork, rubber sheets |

| Rotary Bevel Cutting Machine | Circular gaskets | Non-metallic materials |

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we manufacture all of the above with customizable cutting modules, pressure settings, and feeding systems.

How does an automatic gasket cutting machine work?

Automation might sound complex, but in practice, it simplifies everything.

An automatic gasket cutting machine uses digital input (like CAD files) to guide blades, punches, or rotary tools across a flat surface or through feeding rollers to cut gaskets with precision.

One of my B2B buyers in Canada once said, “We spend more time fixing bad gaskets than making them.” That changed once they started using a CNC rotary bevel cutting machine with real-time adjustments and zero waste.

Core Workflow

- Design Input: Upload a CAD or DXF file with gasket dimensions.

- Material Loading: Sheets or rolls of gasket material are fed into the machine.

- Cutting Process: Machine follows digital paths using knife, punch, or rotary blade.

- Collection: Finished gaskets drop into trays or onto conveyor belts.

Key Automation Features

- Servo motor control for precision movement

- Touchscreen interface for quick programming

- Multi-layer material support

- Real-time monitoring and adjustment

The benefit? You cut more gaskets with higher accuracy and lower material loss.

What features should I look for in an automatic gasket cutter?

A machine is only as good as its controls, compatibility, and speed.

Key features to look for in an automatic gasket cutting machine include digital control compatibility, material flexibility, precise cutting depth control, and high-speed operation with minimal waste.

Many customers ask me: “Can one machine handle different gasket types?” My answer: Yes—if you choose the right model. At Suzhou Haoxinhe, our automatic punching cutting machines come with interchangeable modules that handle foam, plastic, rubber, and PTFE.

Must-Have Features

| Feature | Why It Matters |

|---|---|

| Touchscreen Interface | Quick setup and job switching |

| Blade Pressure Control | Clean cuts for different materials |

| Vacuum Table (for flatbeds) | Keeps material from shifting |

| Material Feeding System | Supports roll or sheet feeding |

| CAD File Import | Makes cutting flexible and repeatable |

Optional Upgrades

- Dust collection system

- Anti-slip rollers

- Temperature-controlled blades (hot & cold)

- Edge detection sensors for irregular sheets

The flexibility of our webbing ribbon cutting machines is why we’re trusted by pharmaceutical and lab industries, where clean gasket edges are critical.

Which industries benefit most from automatic gasket cutters?

Gaskets are everywhere—from HVAC to chemical tanks to food processing lines.

Industries that rely heavily on precise sealing—such as manufacturing, HVAC, pharmaceuticals, and chemicals—gain the most from automatic gasket cutting machines1.

A buyer from Germany once told me their gasket supplier missed a shipping deadline due to manual labor bottlenecks. That led to a full week of lost production. Once they upgraded to our bubble wrap cutting machine with gasket attachments, they took full control of their production line.

Common Applications by Industry

| Industry | Application | Recommended Machine |

|---|---|---|

| HVAC | Pipe sealing | Webbing tape cutting machine |

| Pharma | Sterile container seals | Flatbed CNC knife cutter |

| Automotive | Engine and fluid seals | Rotary bevel cutting machine |

| Chemical | PTFE tank gaskets | Computer tube cutting machine |

| Packaging | Foam gaskets for boxes | Protective foam cutting machine |

Automatic gasket machines not only improve efficiency, but also reduce human error and certification issues. That’s why many of our clients switch from manual to automated systems within 6–12 months.

Conclusion

Automatic gasket cutting machines deliver clean edges, consistent shapes, and fast production—perfect for industries that demand precision.

INSIGHT:

The most effective automatic gasket cutting machines1 combine digital control, material versatility, and customizable settings. Suzhou Haoxinhe’s webbing tape cutting machines3, rotary bevel cutters, and flatbed CNC systems deliver high-quality gasket production for industrial clients worldwide.

Explore this resource to understand how automatic gasket cutting machines enhance efficiency and precision in production processes. ↩ ↩ ↩ ↩ ↩

Learn about the advantages of CNC flatbed cutters in gasket production, including precision and customization options. ↩

Discover the applications and benefits of webbing tape cutting machines in producing various gasket types efficiently. ↩ ↩