What is the best aluminium foil cutting machine1 for high-speed industrial packaging lines?

Struggling with slow, inaccurate foil cuts that disrupt your packaging line?

The best aluminium foil cutting machine for industrial packaging combines high-speed precision2 cutting, stable automation, and robust material handling—guaranteeing zero downtime in continuous operations.

If your business handles thousands of metres of foil every day, a low-performing machine isn’t just inconvenient—it costs time, money, and credibility. Let’s look at how to solve this problem and make sure your equipment keeps up.

How do cutting speed3 and precision2 impact productivity in aluminium foil processing?

Poor speed or accuracy can lead to excessive waste, jams, or downtime—issues that kill profits.

High cutting speed3 increases output per hour, while precision ensures material is used efficiently without costly waste or machine jams. Together, they create stable, uninterrupted packaging flow.

When we talk about aluminium foil cutting in packaging lines, speed and precision aren’t just nice to have—they’re non-negotiable. In high-throughput environments like food packaging or insulation material prep, your machine must operate with the right balance. Let me explain how that plays out in real-life factory scenarios.

The critical role of speed

High-speed production lines often work with narrow tolerances and synchronized tasks. If the cutting machine lags, every step downstream suffers. You’ll experience:

- Backlogged conveyors

- Material misalignment

- Increased energy costs per unit

Let’s say your current machine cuts 50 metres per minute, and your line requires 90. You now either run two machines or slow the entire line. That’s not sustainable.

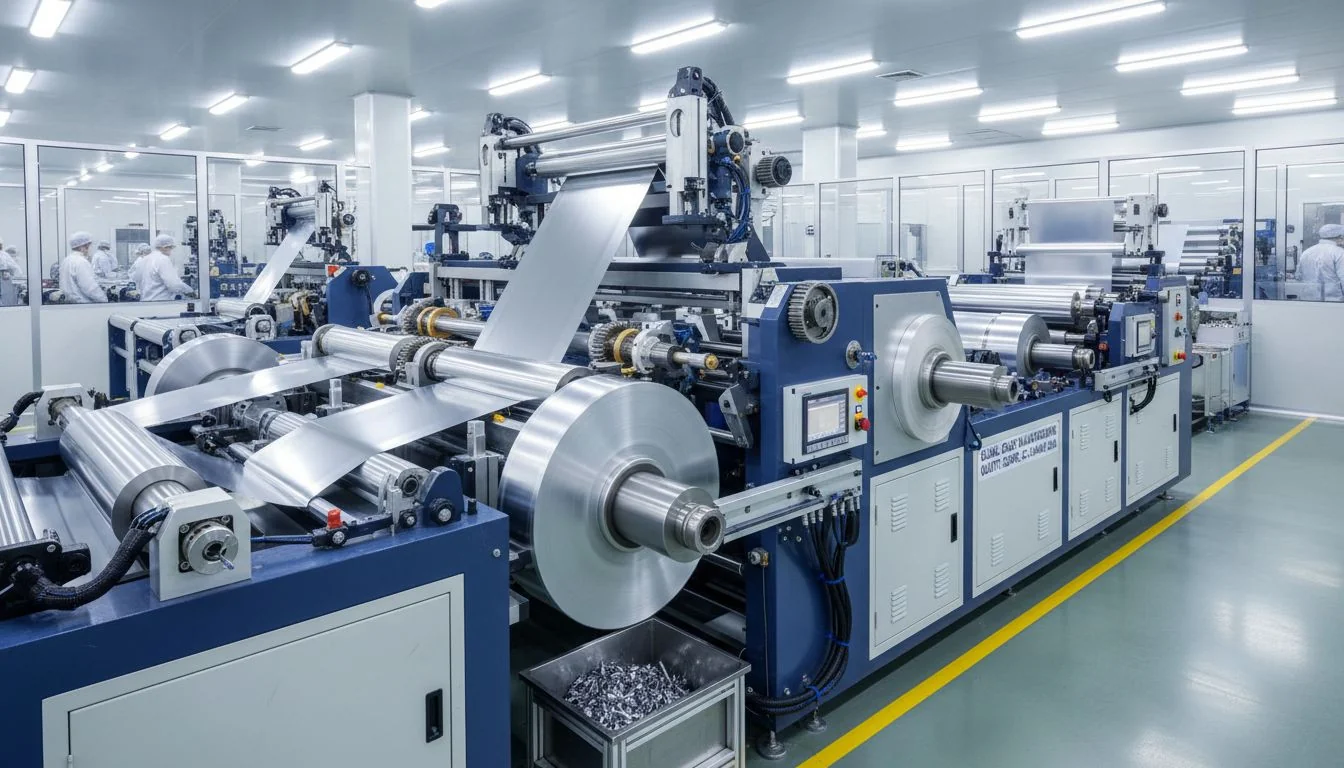

Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers high-speed aluminium foil cutting machine1s designed for industrial-grade loads. Our machines, such as the automatic punching cutting machine and hot and cold cutting machines, can operate at over 120 cuts per minute depending on material thickness and roll width.

Why precision is equally important

Speed without control leads to chaos. Cutting 1,000 metres per shift sounds good—until you realize 10% was wasted due to misalignment or slippage.

Precision keeps material tolerances tight, reduces rework, and avoids customer complaints.

Key features to look for include:

| Feature | Why it matters |

|---|---|

| Servo motor control | Maintains exact length per cut at high speeds |

| Optical sensors & edge trackers | Prevents deviation during unwinding |

| Pressure-adjustable blades | Avoids tearing on thin aluminium foil |

| Stable tension system | Keeps foil taut for accurate measurement |

Our webbing ribbon cutting machines and PVC edge banding cutting machines at HAOXINHE integrate smart systems to ensure foil remains centered and consistent, even at high speeds. These aren’t just fancy extras—they prevent the tiny mistakes that lead to huge losses.

Real-world impact on productivity

If your foil-cutting operation saves 5 seconds per cut, and you do 10,000 cuts a day, that’s 14 hours saved per week. Now add in waste reduction from 5% to 1%—that could mean thousands of dollars retained in material value monthly.

This is why clients from Europe, Canada, and Southeast Asia switch to our machines. They’re built for actual industrial demand—not just specs on paper.

Conclusion

Speed and accuracy directly drive your bottom line—upgrade your machine, and you upgrade your profit.

Insights:

For high-speed packaging lines handling aluminium foil, your cutting machine must combine servo-driven speed, micro-level accuracy, and automation-ready design. Suzhou Haoxinhe Electrical Equipment Co., Ltd. delivers industrial foil cutting solutions—like the rotary bevel cutting machine and the protective foam cutting machine—engineered for non-stop, precision-critical environments. Whether you’re in food packaging, HVAC insulation, or electronics, HAOXINHE’s industrial-grade foil cutting equipment ensures your output is fast, flawless, and future-proof.

Explore this link to understand the essential features that make an aluminium foil cutting machine efficient and reliable. ↩ ↩

Explore why precision is crucial in aluminium foil cutting to avoid waste and ensure quality. ↩ ↩

Understand the impact of cutting speed on production efficiency and overall output in packaging lines. ↩ ↩