What is an Automatic Roll to Sheet Cutting Machine and How Can It Revolutionize Your Production Line?

leading paragraph:

Is your business still manually cutting large rolls into sheets? It’s time to step up your game with an automatic roll to sheet cutting machine1 that will save time, reduce waste2, and boost efficiency.

featured Paragraph:

An automatic roll to sheet cutting machine1 is a device that automatically converts large rolls of material into precise, uniform sheets. It improves production speed, reduces human error, and ensures consistent results, making it an essential tool for many industries.

Transition Paragraph:

But how does this machine work, and why is it so beneficial for manufacturers? Let’s dive into the details of how an automatic roll to sheet cutting machine1 can enhance your operations.

What is an Automatic Roll to Sheet Cutting Machine?

leading paragraph:

If you’re looking for a more efficient way to cut rolls into sheets, an automatic roll to sheet cutting machine could be the solution. Here’s how it works and why it’s vital for your production process.

featured Paragraph:

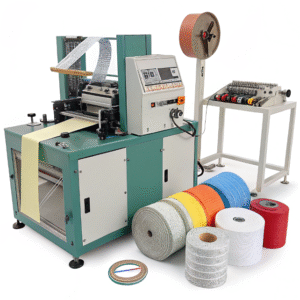

An automatic roll to sheet cutting machine is designed to take a large roll of material—whether it’s paper, film, fabric, or foam—and cut it into sheets of precise size. The machine automates this process, improving speed, accuracy, and reducing the need for manual labor.

[^3] with automation](https://hxcuttingmachine.com/wp-content/uploads/2025/03/factory1.png)

Dive deeper Paragraph:

An automatic roll to sheet cutting machine is ideal for industries that process materials like paper, film, textiles, and even foam. These machines efficiently transform rolls of material into smaller, accurate sheets, reducing the workload on manual labor and minimizing errors.

Suzhou Haoxinhe Electrical Equipment Co., Ltd., a renowned manufacturer of cutting machines, offers automatic roll to sheet cutting machine1s that handle various materials, including webbing, PVC edge banding, and protective foams. These machines are designed to work at high speeds while maintaining cutting precision, allowing businesses to scale production without sacrificing quality.

Key Benefits of Automatic Roll to Sheet Cutting Machines:

- Precision: Cuts materials into uniform sheets with exact dimensions, eliminating the guesswork of manual cutting.

- Speed: Capable of cutting large rolls at a much faster rate than manual methods, improving overall production time.

- Reduced Labor Costs: Automation reduces the need for human intervention, saving on labor costs and minimizing the risk of human error.

- Waste Reduction: Cuts are more accurate, meaning there’s less leftover material and waste, contributing to cost savings.

These benefits help businesses maintain high production standards and reduce operational costs, making the investment in an automatic roll to sheet cutting machine worthwhile.

How Does an Automatic Roll to Sheet Cutting Machine Work?

leading paragraph:

Curious about how an automatic roll to sheet cutting machine operates? Let’s break down its components and see how it efficiently transforms large rolls into perfect sheets.

featured Paragraph:

The automatic roll to sheet cutting machine operates by pulling material from a roll, measuring it to the required sheet size, and cutting it with precision. The entire process is automated, reducing labor costs and increasing efficiency.

Dive deeper Paragraph:

The process starts when the material is loaded onto the machine. The roll is placed into the feeding system, where it is unrolled and prepared for cutting. The machine’s sensors align and measure the material to ensure accuracy before the cutting blade goes to work.

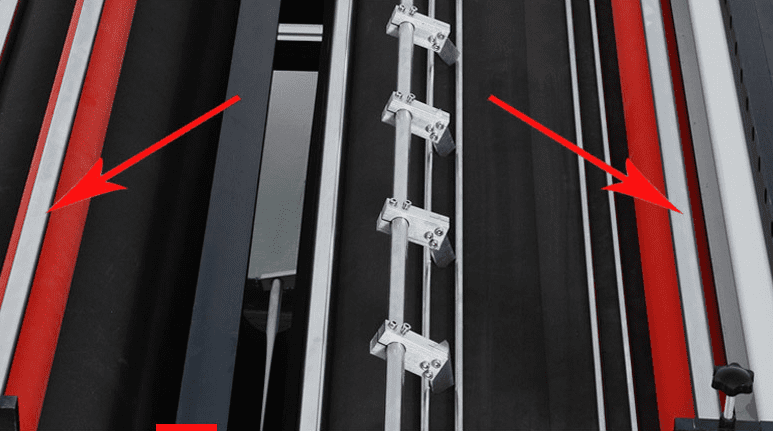

- Feeding Mechanism: The material is fed from the roll into the cutting system. The feeding system ensures the material moves smoothly without tangling or slipping.

- Measurement and Alignment: Once the material is in place, the machine uses sensors to measure the desired length of each sheet and aligns the material accordingly.

- Cutting Mechanism: A sharp blade or rotary cutter slices the material at precise intervals, cutting it into uniform sheets.

- Waste Handling: The system can automatically handle waste material, either by rolling it up or discarding it, which helps keep the work area clean and efficient.

The control panel allows operators to set parameters like sheet length, cutting speed, and material type, ensuring that the machine is versatile enough to handle various cutting needs.

Features of an Automatic Roll to Sheet Cutting Machine:

- Automatic Feeding: Reduces manual labor and improves material handling.

- Sensor-Controlled Measurement: Guarantees precise and uniform cuts.

- Adjustable Settings: Allows customization for different materials and sheet sizes.

- Waste Management System: Ensures minimal waste and a cleaner work environment.

These features make the automatic roll to sheet cutting machine a highly efficient and adaptable tool for businesses.

Why Should You Invest in an Automatic Roll to Sheet Cutting Machine?

leading paragraph:

Wondering if an automatic roll to sheet cutting machine is worth the investment? Here’s why it could transform your production line.

featured Paragraph:

Investing in an automatic roll to sheet cutting machine1 improves production efficiency, cuts labor costs, and ensures high-quality results. It’s a smart investment for businesses looking to enhance their cutting processes and scale up production.

Dive deeper Paragraph:

The key advantage of an automatic roll to sheet cutting machine is its ability to improve production efficiency. Traditional methods of cutting large rolls into sheets are time-consuming and prone to errors. By automating this process, businesses can increase output and ensure that each sheet is cut to the exact dimensions needed.

Additionally, these machines allow for faster production speeds. Instead of relying on a team of workers to cut material manually, an automatic machine handles the entire process at a faster rate, freeing up labor for other tasks. This leads to significant labor cost savings over time.

Moreover, the machine’s precision reduces material waste, which is a critical factor for industries that rely on expensive materials. The consistency of each cut ensures that there is minimal leftover material, which translates into lower production costs.

An automatic roll to sheet cutting machine can also improve the overall quality of your products. The uniformity of each sheet ensures that your output meets high-quality standards, which is essential for industries like packaging, textiles, and manufacturing.

Conclusion

An automatic roll to sheet cutting machine is an essential investment for businesses looking to streamline their cutting processes, increase efficiency, and reduce operational costs.

Insights:

An automatic roll to sheet cutting machine1 from Suzhou Haoxinhe Electrical Equipment Co., Ltd. significantly enhances production efficiency3, precision, and cost-effectiveness. With the ability to handle a variety of materials like webbing tape, PVC edge banding, and protective foam, our cutting machines streamline operations by reducing labor costs, minimizing waste, and ensuring consistent, high-quality cuts. By automating the roll-to-sheet process, businesses can scale production, meet tight deadlines, and maintain competitive pricing—all while improving the overall product quality.

Explore this link to understand how this technology can enhance efficiency and precision in your production line. ↩ ↩ ↩ ↩ ↩ ↩

Learn about innovative approaches to minimize waste and improve sustainability in your manufacturing processes. ↩

Discover strategies and technologies that can significantly boost production efficiency in your operations. ↩