What is an Automatic Ribbon Cutting Machine and How Does It Benefit Your Business?

leading paragraph:

If you’re in the manufacturing or packaging industry, you’re likely familiar with the challenges of cutting ribbons consistently and efficiently. An automatic ribbon cutting machine1 can save time and improve precision in this critical process.

featured Paragraph:

An automatic ribbon cutting machine1 is designed to cut ribbons or tapes into precise lengths with minimal manual intervention. It improves efficiency, consistency, and reduces labor costs, making it an essential tool for industries that rely on ribbon cutting in production.

Transition Paragraph:

But how exactly does it work, and why should you consider upgrading to an automatic ribbon cutting machine? Let’s dive deeper into this topic and explore how it can make a significant difference to your workflow.

What is an Automatic Ribbon Cutting Machine?

leading paragraph:

Does your production line still rely on manual cutting for ribbons and tapes? It might be time to consider an automatic solution that can streamline your operations.

featured Paragraph:

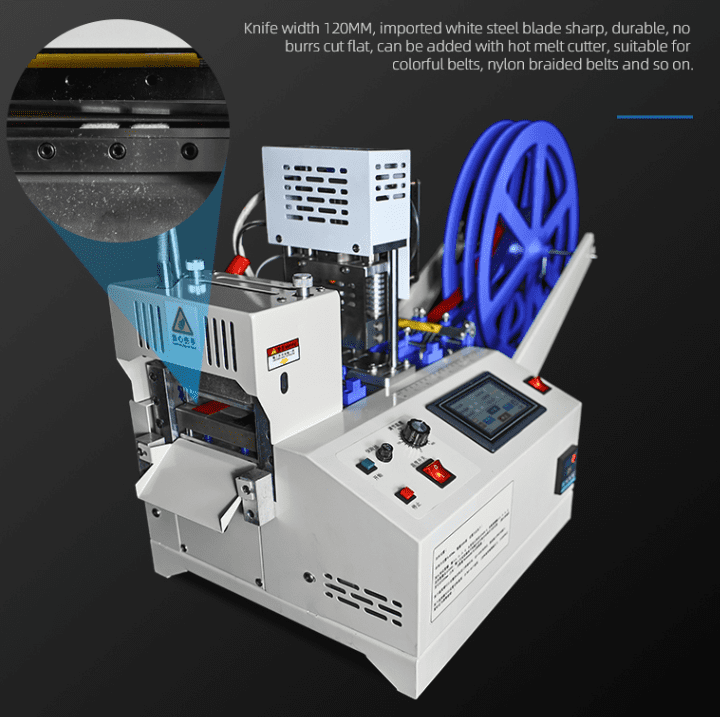

An automatic ribbon cutting machine is engineered to automate the cutting of ribbon, tape, or other similar materials into preset lengths. The machine ensures uniformity and high throughput, saving valuable time and reducing human error.

Dive deeper Paragraph:

An automatic ribbon cutting machine is an invaluable asset for companies looking to improve production efficiency. Unlike manual cutting, which is prone to variations in length, speed, and accuracy, an automatic machine uses precision technology to cut ribbons to exact specifications every time.

These machines are equipped with a series of sensors and automated mechanisms that can adjust to different ribbon sizes, lengths, and materials without requiring constant supervision. For example, the Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers a variety of cutting machines, including models specifically designed for cutting webbing ribbons, protective foams, and PVC edge banding.

Key Features of an Automatic Ribbon Cutting Machine:

- High Precision: The machine ensures that each cut is accurate to the exact length you need, which is particularly important when dealing with materials like ribbons that require precision.

- Speed and Efficiency: Automatic machines can cut ribbons at much faster rates than manual methods, helping to increase the overall throughput of your production line.

- Customization: Many models are customizable, allowing businesses to adjust the length, size, and even the speed of the cutting process to suit their specific needs.

- Reduced Labor Costs: By automating the cutting process, businesses can reduce the need for manual labor, thereby cutting down on labor costs and minimizing human error.

Incorporating such a cutting machine into your operations could revolutionize your production line by increasing efficiency and ensuring quality consistency.

How Does an Automatic Ribbon Cutting Machine Work?

leading paragraph:

Curious about how an automatic ribbon cutting machine works? Understanding the mechanics behind these machines can help you make informed decisions for your business.

featured Paragraph:

Automatic ribbon cutting machines use an integrated system of motors, sensors, and controllers to cut ribbons with precision. The materials are fed into the machine, and the system automatically adjusts settings to cut the ribbon into predefined lengths.

Dive deeper Paragraph:

The core of an automatic ribbon cutting machine is its electronic control system, which provides precise operation through a series of programmed commands. The machine begins by feeding the ribbon into a cutting mechanism, where sensors monitor the material’s length and adjust the cutting tool accordingly.

This setup ensures that every ribbon cut is identical, whether you’re dealing with simple fabric ribbons or more complex materials like foam or PVC tapes. The Suzhou Haoxinhe Electrical Equipment Co., Ltd. models are designed to handle a variety of materials, such as webbing tape, PVC edge banding, and even protective foam cutting.

An automatic ribbon cutting machine typically includes:

- Feeding System: Feeds the ribbon or tape into the cutting mechanism at a consistent speed.

- Cutting Mechanism: Uses either a blade or rotary cutter to slice the ribbon into precise lengths.

- Control System: Allows the operator to set the cutting length, adjust speed, and monitor the process.

- Waste Management: Many machines include systems to handle the waste material, ensuring the workspace remains clean and efficient.

These machines are designed to reduce downtime and improve throughput by minimizing the need for human intervention. The result is faster, more reliable production, which is crucial in industries where time is money.

Why Should You Invest in an Automatic Ribbon Cutting Machine?

leading paragraph:

Still on the fence about whether to invest in an automatic ribbon cutting machine1? Here’s why it might be the best move for your business.

featured Paragraph:

Investing in an automatic ribbon cutting machine allows businesses to scale production, improve cutting consistency, and reduce manual labor costs. It is an excellent solution for manufacturers looking to enhance efficiency and reduce waste.

Dive deeper Paragraph:

One of the biggest advantages of an automatic ribbon cutting machine is its ability to increase efficiency across production lines. In industries like packaging, pharmaceuticals, or textiles, the need for precise, rapid cuts is constant. Manual cutting, on the other hand, can introduce significant delays and errors.

With automation, the cutting process becomes much faster. For instance, in the textile industry, where ribbons are often cut to specific lengths for packaging or finishing, an automatic cutting machine can handle continuous tasks without stopping for breaks. Moreover, these machines are often equipped with sensors to detect problems like material jams, which helps prevent costly errors.

Additionally, the machines are designed with customization in mind. Whether you need to cut ribbons of varying lengths or deal with different materials, the automatic ribbon cutting machine can be programmed to adjust settings, allowing businesses to cater to various product requirements.

Finally, from a business standpoint, reducing manual labor and increasing production speeds results in a quicker return on investment (ROI). By automating the cutting process, companies can focus more on expanding other areas of production or improving product quality, rather than dealing with labor shortages or errors.

Conclusion

An automatic ribbon cutting machine is an essential investment for businesses that prioritize efficiency, precision, and scalability in their production process.

Insights:

An automatic ribbon cutting machine is a game-changer for businesses looking to improve cutting precision, speed, and reduce labor costs2. Its ability to handle various materials with ease and adaptability makes it a must-have in many industries.