What is an automatic plastic tube cutting machine1 and how does it improve production efficiency2?

Are you tired of wasting time, labor, and material due to inaccurate tube cutting?

An automatic plastic tube cutting machine1 increases productivity, reduces labor, and ensures precise cuts for every batch of plastic tubing.

This post will help you understand how these machines work, where to use them, and how to choose the right one for your factory. If you’re sourcing from China or looking to upgrade your current cutter, don’t miss this.

What does an automatic plastic tube cutting machine1 do?

You might be struggling with manual labor costs, inconsistent cutting lengths, or even damaged materials.

An automatic plastic tube cutting machine1 automates the process of cutting plastic tubes into fixed lengths, with high speed and accuracy, saving time and reducing errors.

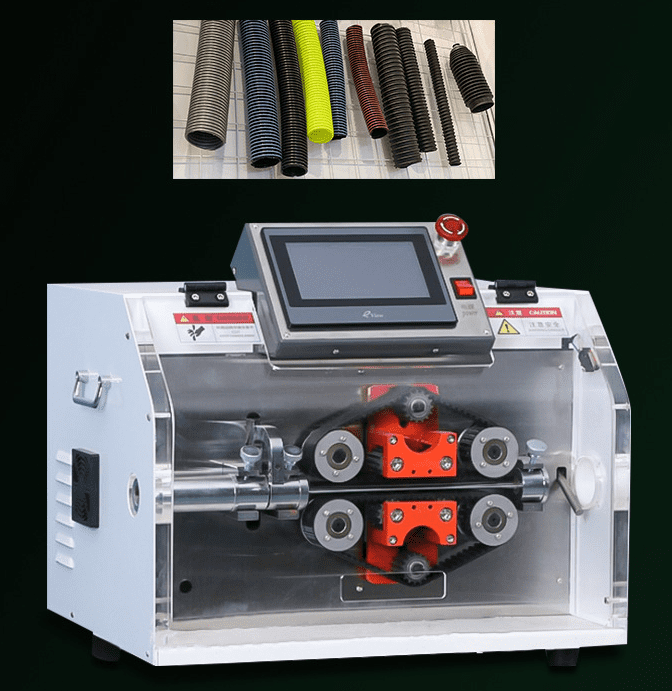

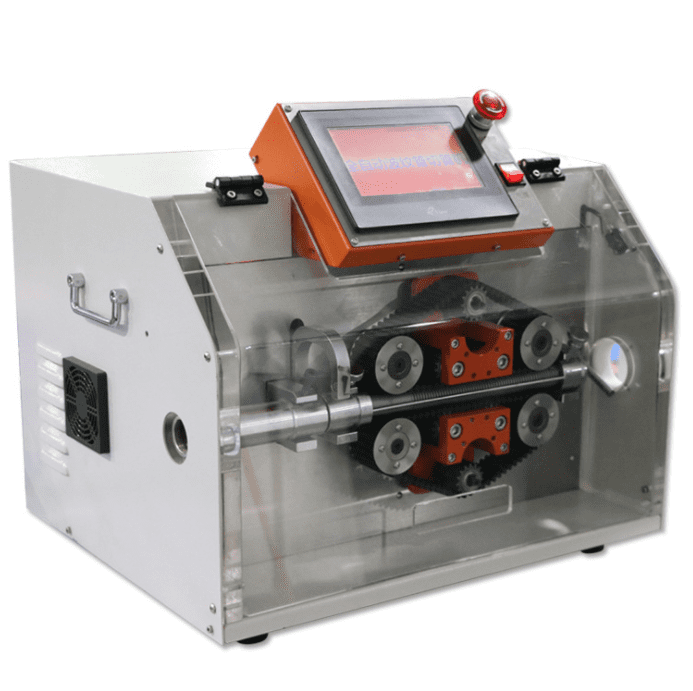

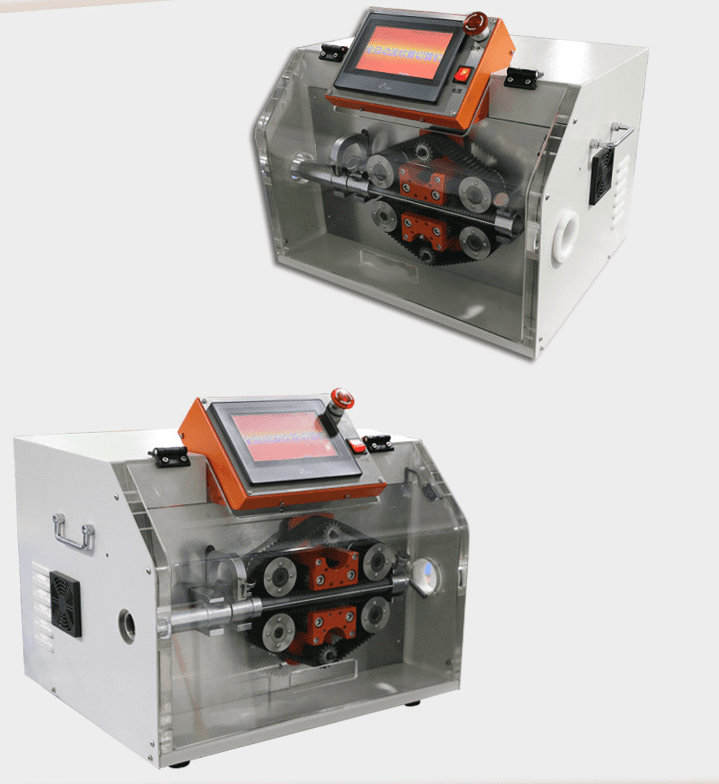

These machines are equipped with motors, sensors, and digital controllers. They pull in the tubing, measure the desired length, and use a blade—either cold or hot—to make the cut. Some models also offer additional functions like punching, beveling, or batch counting.

Main Functions and Benefits

| Function | Benefit |

|---|---|

| Automatic feeding | Consistent speed and reduced labor |

| Length control system | High precision, down to 0.1mm |

| Hot/cold blade options | Suitable for various plastic types |

| Touchscreen programming | Easy to operate, minimal training |

| Batch processing | Cuts 1,000+ pieces per hour |

For example, at Suzhou Haoxinhe Electrical Equipment Co., Ltd., we manufacture and export various models like computer tube cutting machines, wire cutting and stripping machines, and PVC edge banding cutting machines. These are widely used across industries, including automotive, medical, HVAC, and packaging.

Why is accuracy so important when cutting plastic tubes?

Maybe you’ve noticed clients complaining about misfitting components, or your rework rate has gone up.

Accurate cutting reduces waste, improves product consistency, and ensures that your components meet strict client requirements.

When tubes are cut even 1mm too short or too long, the result might be functional failure or extra labor costs. For example, in the HVAC industry, plastic tubing must fit precisely into connectors. If not, the entire assembly may leak or require manual trimming. That’s unacceptable in high-volume production.

What Impacts Accuracy?

- Sensor Quality: Better sensors mean more precise length detection.

- Material Type: Softer plastics may stretch, affecting length if not handled properly.

- Blade Condition: Dull blades may deform the material, rather than cut cleanly.

- Tension Control: Machines with tension regulators keep feed speed constant.

Suzhou Haoxinhe’s hot and cold cutting machines come with digital controls and auto-correction features, which help minimize variation. We use imported stepper motors and Mitsubishi controllers for better reliability. That’s why clients in Germany and Canada keep returning to us.

How do I choose the right automatic plastic tube cutting machine1?

You’re probably overwhelmed with options online and unsure what specs actually matter.

Choose based on your tube material, cutting size range, production speed, and extra functions like punching or beveling. Always request certifications and test videos before placing an order.

Here’s how I help clients like Mark from Canada, who sources plastic tube cutting machines for HVAC tubing. He compares machines across 5 suppliers, but often gets stuck due to vague specs and unclear certifications. I usually walk him through the following:

Key Selection Criteria

| Feature | What to Check |

|---|---|

| Material Compatibility | Can it handle PVC, PE, PU, etc.? |

| Cutting Speed | Measured in cuts/minute or m/min |

| Cutting Accuracy | ±0.1mm preferred for precision jobs |

| Blade Type | Hot for sealed edges, cold for clean |

| Certifications | CE, ISO, etc. (Verify originals!) |

| Warranty & Support | At least 1 year with after-sales team |

I always send clients real cutting videos, list all specs transparently, and offer custom solutions. If you need to cut both tubes and webbing, our multi-purpose automatic cutting machines are the ideal choice.

What industries use plastic tube cutting machines the most?

You might wonder if this machine is just for plastic factories or something more versatile.

These machines are widely used in medical, automotive, chemical, and HVAC industries, as well as packaging and lab supply production.

In fact, many labs need precise tubing for fluid transfer. Medical device manufacturers cut tiny silicone tubes for catheters. In the automotive world, fuel and air lines rely on accurate tube lengths. Delays or inconsistencies here can literally cost lives or millions.

Common Applications

- Medical: silicone tubes for IV and drainage

- Automotive: plastic air and fuel lines

- Packaging: tubes for liquid dispensers

- HVAC: drainage pipes and insulation sleeves

- Construction: conduit or protection sleeves

- Chemical: sample handling systems

Our clients in France and Singapore often require protective foam cutting machines or rotary bevel cutting machines to handle tubing with unique profiles. We customize machines to match each application, including software and mechanical parts.

Conclusion

Automatic plastic tube cutting machines are essential tools to boost efficiency, ensure precision, and lower labor costs in modern production.

Insights

An automatic plastic tube cutting machine1 cuts plastic tubing with speed and precision, using programmable settings to ensure consistent lengths. It’s ideal for industries requiring high accuracy, such as medical, HVAC, and automotive sectors. Key considerations when choosing a machine include material compatibility, cutting accuracy3, and certification. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers customizable solutions for various tube-cutting needs, supporting B2B buyers with reliable quality and transparent communication.

Explore this link to understand how automatic plastic tube cutting machines enhance productivity and precision in manufacturing processes. ↩ ↩ ↩ ↩ ↩ ↩

Discover strategies and technologies that can significantly boost production efficiency in various industries. ↩

Learn about the significance of cutting accuracy in production and how it impacts product quality and efficiency. ↩