What is an Automatic Paper Roll Cutter and How Does It Improve Production Efficiency?

Manually cutting paper rolls is slow, inconsistent, and labor-intensive. If you’re scaling up, you need a smarter way to process roll materials.

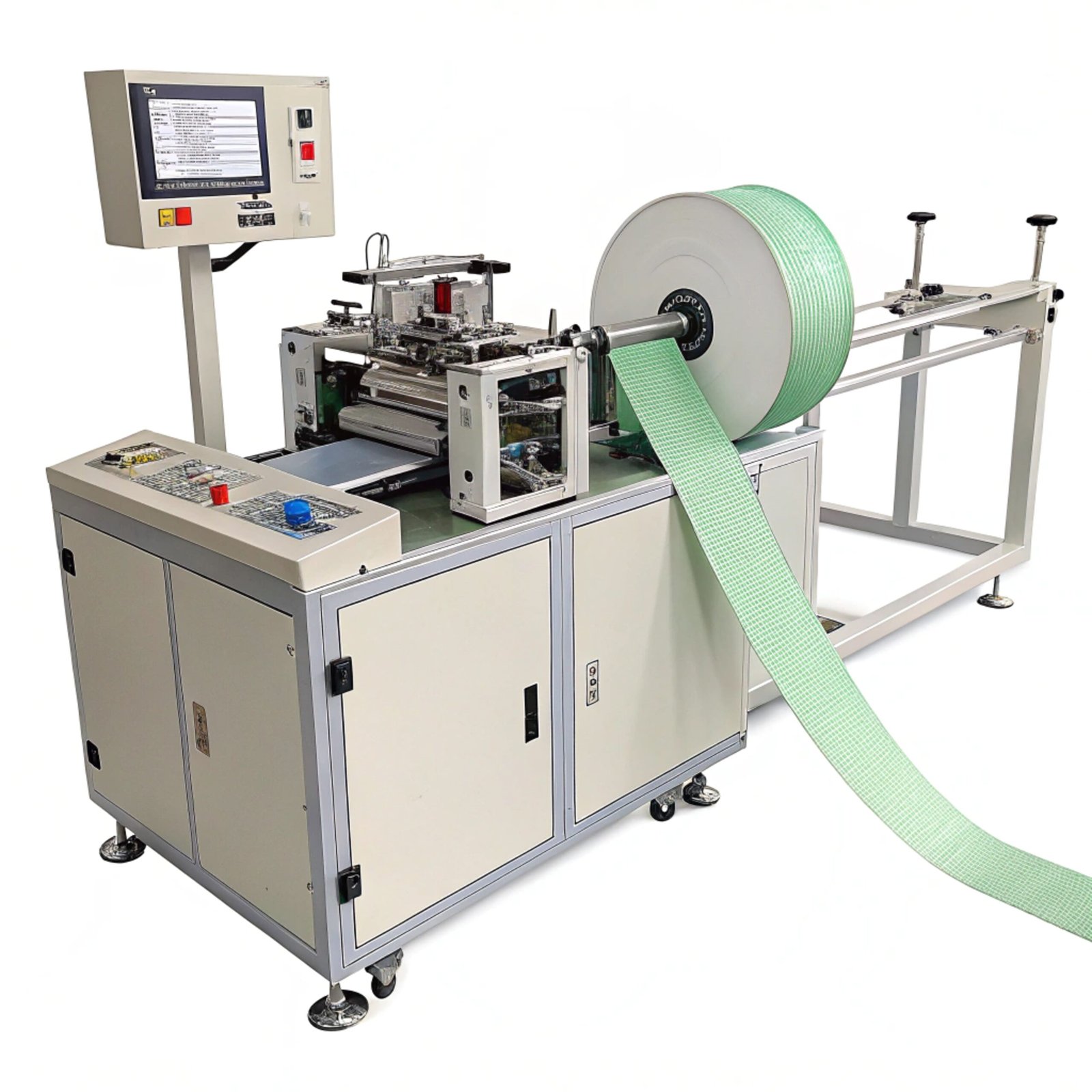

An automatic paper roll cutter is an industrial machine that feeds, measures, and cuts large rolls of paper into sheets or fixed lengths—automatically and with precision.

Let’s explore how it works, what it cuts, and why manufacturers in printing and packaging rely on it daily.

What Does an Automatic Paper Roll Cutter Do?

Large rolls of kraft paper, sticker backing, film, or laminated sheets need to be processed into usable sizes. Manual tools are too slow and risky for commercial operations.

An automatic paper roll cutter unwinds the roll, feeds it forward using servo motors, measures the correct length, and cuts it cleanly—without operator involvement.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we manufacture precision paper roll cutting machines for:

- Kraft paper

- Bubble wrap

- Laminated or coated paper

- Film rolls with adhesive backing

- Non-woven paper

- Paperboard sheets

These machines are trusted by clients in Europe, North America, and Southeast Asia who need high-throughput and consistent cutting quality.

Key Features of Our Automatic Paper Roll Cutter

| Feature | Function |

|---|---|

| Servo Motor Feed | Consistent length control with millimeter precision |

| Programmable Control Panel | Set length, speed, quantity with touch display |

| Rotary or Straight Blade Options | Cuts cleanly through thin to mid-thickness materials |

| Tension Control System | Prevents wrinkling or slipping during roll feed |

| Auto-Stop & Jam Sensors | Reduces machine damage and product waste |

One of our clients in Italy needed to process coated kraft paper rolls without tearing the outer film. We customized a machine with non-stick rollers and low-friction guides—now he runs 10,000 sheets/day without defects.

How Does the Machine Work?

The automatic paper roll cutter integrates software, servo motors, and high-speed blades to automate the cutting process.

Step-by-Step Workflow:

Loading the Roll

Roll is mounted on the unwind shaft with optional tension arms.Feeding and Measurement

The servo motor feeds the paper at a steady speed while encoders measure exact lengths.Blade Activation

A rotary or guillotine blade slices the paper into sheets at the pre-set length.Stacking or Conveyor Transfer

Cut pieces are dropped into bins or sent to the next production stage.

This system can run continuously for hours with minimal operator supervision.

What Materials Can It Cut?

| Material | Common Applications |

|---|---|

| Kraft Paper | Packaging liners, wrapping sheets |

| Laminated Paper | Food trays, medical pouches |

| Label Backing Paper | Printing and label industries |

| Bubble Wrap Sheets | E-commerce and shipping use |

| EVA Foam Sheets | Protective packaging inserts |

| PVC Coated Paper | Advertising or adhesive sheet production |

Every machine from HAOXINHE can be tested using your own material samples before delivery.

Why Use an Automatic Paper Roll Cutter?

Manual labor introduces variability and bottlenecks. This machine solves both.

Benefits for Your Factory:

- Faster Output: Run thousands of cuts per shift

- Less Labor: One operator can monitor the entire system

- Better Accuracy: Cuts are exact, down to 0.1 mm

- Consistent Quality: Every sheet is uniform

- Less Waste: Precise feeding means lower scrap rates

A Singaporean client processing 800mm-wide rolls for inner box liners reduced their labor by 50% after installing our automatic cutter.

Why Choose Suzhou Haoxinhe?

We design and build custom machines based on your real production needs. You’re not getting a one-size-fits-all machine—we tailor the cutter for your material, speed, and factory layout.

What You Get With Us:

- Factory-direct pricing

- Custom roll widths (from 300mm to 1600mm)

- High-speed models for mass production

- Optional edge sensors and batch counting

- Global shipping + remote support

We work with B2B clients in HVAC, packaging, label printing, automotive, and more.

Who Should Use This Machine?

This machine is ideal for:

- Packaging converters

- Printing factories

- Label and adhesive sheet producers

- E-commerce supply manufacturers

- Industrial paper processors

If you handle paper or film rolls on a daily basis and want consistent, fast output—this machine pays for itself quickly.

Conclusion

An automatic paper roll cutter improves speed, precision, and quality. It’s the best solution for converting large paper rolls into sheet form efficiently and consistently.

Insights:

An automatic paper roll cutter is a high-speed industrial machine that converts rolled materials into sheet format. It uses programmable controls, servo motors, and rotary blades to cut kraft paper, coated sheets, film, foam, and other materials accurately. Suzhou Haoxinhe Electrical Equipment Co., Ltd. builds customizable, servo-driven roll cutters for packaging, labeling, printing, and industrial processing factories worldwide. With tension control, digital settings, and safe operation, it’s a must-have tool for scale-focused manufacturers.