What is an Automatic Leather Cutting Machine and How Can It Improve Your Production?

Manual leather cutting is slow, wasteful, and inconsistent. That’s a big problem for factories handling large-volume leather goods.

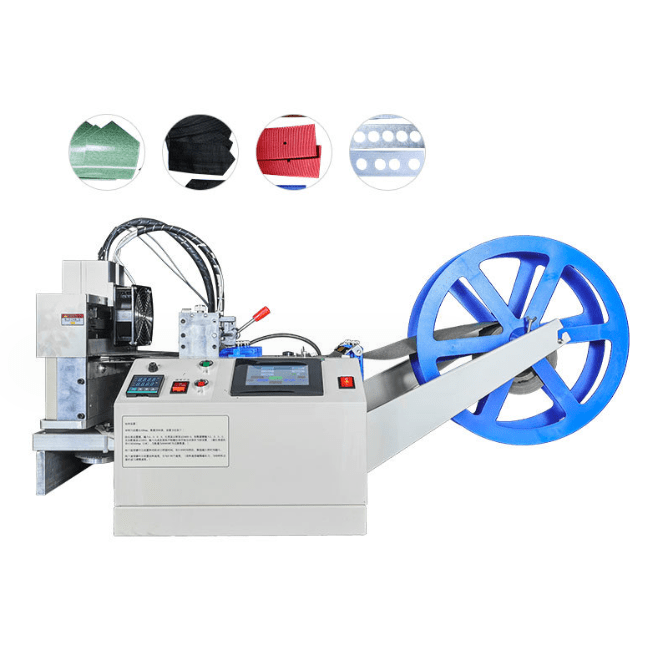

An automatic leather cutting machine is a programmable industrial cutter designed to handle thick, tough leather with precision, speed, and minimal waste.

Let me explain how this machine works, what materials it can cut, and why it’s become a must-have in modern manufacturing.

What Does an Automatic Leather Cutting Machine Do?

Traditional methods like hand-cutting or steel dies can’t keep up with demand. They also limit flexibility and increase labor costs.

An automatic leather cutting machine automates the entire process—feeding, aligning, and cutting leather sheets or rolls into precise shapes or strips.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our machines are used to cut:

- Natural leather sheets

- Synthetic leather (PU, PVC)

- Microfiber leather

- Suede and bonded leather

- Embossed or patterned hides

We’ve worked with clients producing shoes, bags, car interiors, and even custom furniture—each requiring reliable, high-speed leather processing.

Key Features of Our Leather Cutting Machine

| Feature | Description |

|---|---|

| High-Torque Servo Motors | For cutting thick leather with stability |

| Oscillating Knife System | Cuts complex shapes smoothly |

| Digital File Input | Supports DXF, PLT, and AI formats |

| Pressure Control System | Adjusts force depending on leather type |

| Vision Positioning (Optional) | Aligns cuts based on texture or print layout |

For example, one of our clients in Italy needed to cut soft PU leather into shoe upper patterns. We customized a digital oscillating knife cutting machine with smart path optimization. It reduced waste by 25% and doubled his output speed.

How Does the Machine Work?

The automatic leather cutter uses software, servo motors, and high-speed blades to deliver precision cutting across various leather types.

Step-by-Step Process:

Material Loading

The leather sheet or roll is placed on a flatbed or conveyor system.Material Scanning (Optional)

A camera scans textures, colors, or printed guidelines for smart positioning.File Input

Cutting patterns are uploaded via USB or network using formats like DXF or AI.Blade Selection

Based on material thickness, the system selects an oscillating knife, rotary blade, or laser (for some synthetic leathers).Cut Execution

The cutter follows the programmed path at high speed, making clean cuts with no burning or edge damage.Stacking / Offloading

Cut pieces are automatically sorted or sent to the next production step.

What Types of Leather Can It Cut?

| Material Type | Use Case |

|---|---|

| Natural Leather | High-end shoes, wallets, belts |

| PU Synthetic | Handbags, sofas, car interiors |

| Microfiber | Sports shoes, apparel lining |

| Embossed Leather | Branded fashion accessories |

| Faux Leather | Promotional items, packaging |

At HAOXINHE, we test all material samples before shipping machines. This ensures our clients get the right settings and blade type for their use case.

Why Choose HAOXINHE’s Leather Cutting Machines?

We build industrial-grade cutting machines with long-term durability, precise motion control, and smart customization options.

Our advantages:

- Custom blade systems (oscillating, round, drag knife)

- Dual-head options for higher throughput

- Intelligent nesting software to minimize leather waste

- Adjustable pressure control for uneven hides

- Remote training and setup assistance

Our automatic leather cutting machines are already used in:

- Footwear factories

- Bag and luggage manufacturing

- Automotive interiors

- Upholstery and furniture

- Custom leatherwork shops

Many of our B2B buyers—including Mark from Canada—used to buy leather pre-cut at a premium. After switching to our equipment, they now cut in-house, saving up to 40% on raw material costs.

Conclusion

An automatic leather cutting machine gives you the power to cut thick, valuable materials with speed, accuracy, and zero fraying. It’s the perfect upgrade for any leather goods manufacturer.

Insights:

An automatic leather cutting machine is a digital, programmable system that cuts natural or synthetic leather with precision and speed. It replaces manual labor and die-cutting with oscillating knife or rotary blade technology, improving output and minimizing waste. Ideal for bags, shoes, automotive interiors, and furniture, these machines handle PU, suede, microfiber, and real leather. Suzhou Haoxinhe Electrical Equipment Co., Ltd. provides customizable, high-speed leather cutting solutions designed for industrial factories that need reliable performance, minimal downtime, and excellent after-sales support.