What is an Automatic Label Cutting Machine and Why is It Essential for High-Volume Production?

Manually cutting printed labels or fabric tags wastes time and creates uneven edges. That leads to poor product presentation and wasted materials.

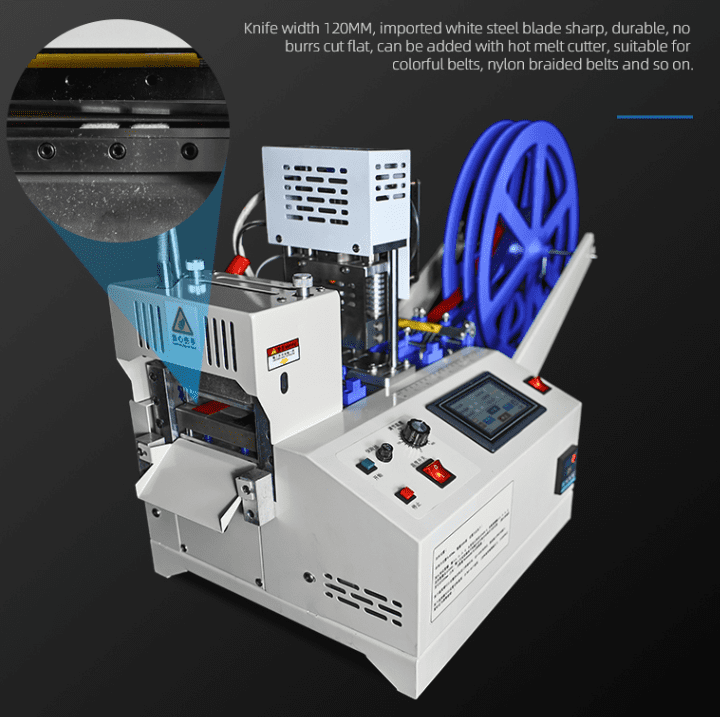

An automatic label cutting machine1 is a programmable cutter designed to precisely cut fabric labels, woven tags, or printed ribbons in large volumes, quickly and consistently.

If your business deals with bulk label production, using the right machine will improve quality and reduce costs instantly.

What Does an Automatic Label Cutting Machine Do?

Labels are small but critical. Poorly cut edges, off-lengths, or jagged finishes can hurt your product image. That’s especially true in industries like fashion, printing, and packaging.

An automatic label cutting machine1 feeds, measures, and cuts label materials—like satin, taffeta, cotton, or polyester—into accurate lengths using hot or cold blades.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we manufacture high-speed label cutting machines optimized for:

- Brand logo labels

- Care instruction tags

- Washable fabric labels

- Woven ribbons for apparel

- Heat-transfer printed label strips

These machines can be adjusted to cut different materials at different lengths. Our clients often run multiple product lines without changing machines—just switching the presets.

Key Features of Our Label Cutting Machine

| Feature | Description |

|---|---|

| High-Speed Cutting | Up to 200 cuts per minute depending on label size |

| Hot & Cold Knife Options | For sealing synthetic or cutting natural fabric edges |

| Length & Batch Control | Accurate to within 0.1mm with programmable settings |

| Multi-Language Touch Panel | User-friendly for global operators |

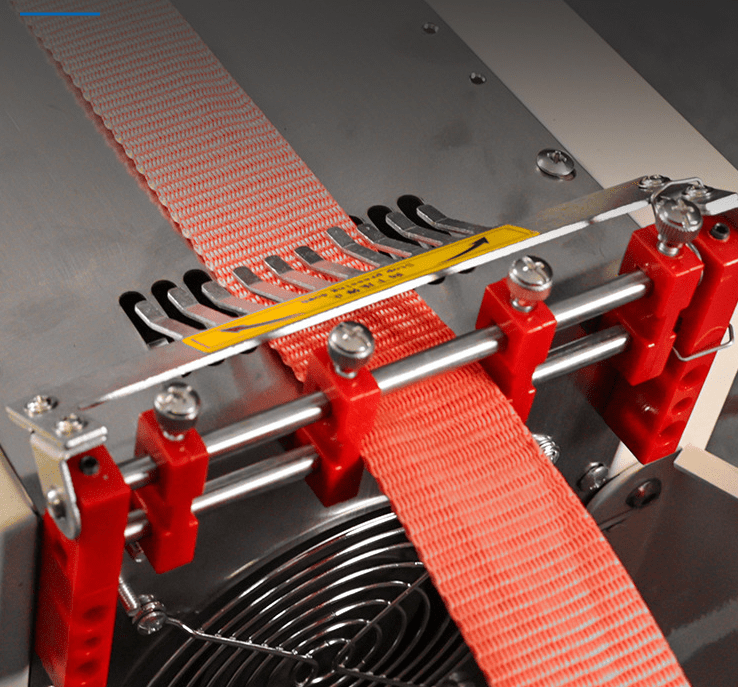

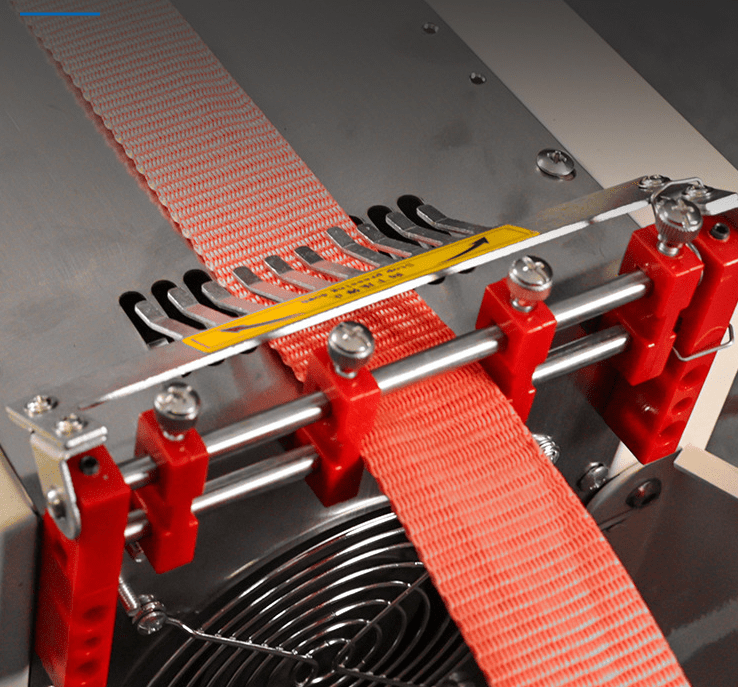

| Auto Feeding Rollers | Reduces manual labor and ensures stable material feed |

| CCD Sensor (Optional) | Aligns printed logos for precision placement |

One of our French clients was struggling with label rolls shifting during manual cuts. We customized our computerized hot knife label cutting machine to include CCD photo sensors2, so the cutter detects print marks and cuts right between logos. No misaligned branding, no waste.

How Does the Machine Work?

The automatic label cutting machine1 automates the full process:

Material Loading

The label roll is placed on an adjustable spindle and aligned.Feeding Mechanism

Servo motors feed the material at the correct tension and speed.Length Measurement

Sensors or encoders measure the precise length per cut.Blade Cutting

Depending on the setup, a hot knife (for synthetic labels) or a cold blade (for natural fibers) executes the cut.Batch Collection

The machine stacks or drops the cut labels into a bin for packaging or sewing.

This is ideal for businesses that need to process thousands of tags or ribbons per day, without manual labor slowing them down.

What Materials Can It Cut?

Our machines handle a wide range of label materials:

| Material Type | Example |

|---|---|

| Synthetic Woven | Satin, Polyester, Nylon |

| Printed Film | Heat-transfer label film |

| Cotton Tape | Garment labels |

| Taffeta | Lightweight printed tags |

| Ribbon | Branded packaging strips |

The HAOXINHE automatic label cutting machine1 supports multiple production scenarios—from luxury fashion tags to printed adhesive label backings.

Why Choose Suzhou Haoxinhe Electrical Equipment Co., Ltd.?

We are a trusted manufacturer of industrial-grade cutting solutions. Our machines are built for durability, customization, and high-speed output.

Our label cutting machines are already in use in:

- Fashion production facilities

- Packaging and printing houses

- Textile labeling factories

- OEM branding departments

We Offer:

- Custom knife types (round, flat, hot, cold)

- Optional punching and half-cut functions

- Smart control panels in English, French, Spanish, etc.

- 1-on-1 remote setup support

- Factory pricing for wholesale buyers

Buyers like Mark from Canada choose us because we provide cutting solutions, not just machines. Whether you need to cut 100mm long care labels or 300mm printed ribbons, we can configure the machine for you.

Conclusion

An automatic label cutting machine1 saves time, improves cutting accuracy, and reduces labor costs—making it an essential tool for any label-producing business.

Insights:

An automatic label cutting machine1 is a programmable cutting system designed to process woven, printed, or heat-transfer label materials into clean, precise pieces. Using cold or hot knife blades, it seals synthetic labels and prevents fraying. The machine supports high-speed, high-volume production with features like batch counting, servo-driven feeding, and optional CCD sensors for cutting printed logos accurately. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers customizable, industrial-grade label cutting machines ideal for fashion, packaging, and printing businesses worldwide.