What is an Automatic Hot Knife Ribbon Webbing Cutter?

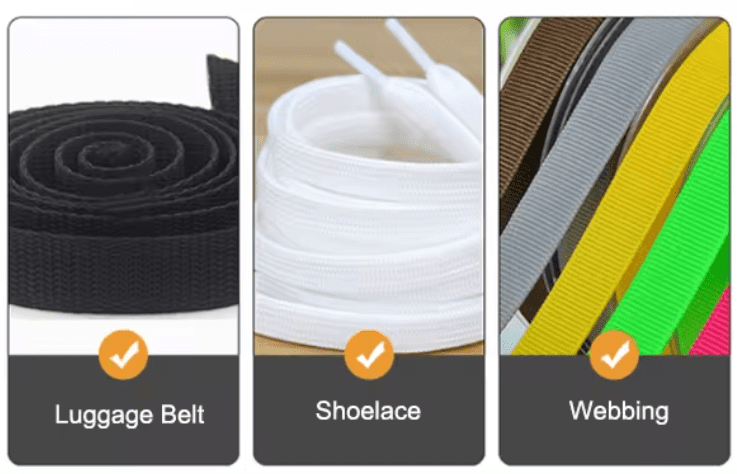

Cutting synthetic webbing1 or ribbon by hand leaves frayed edges and uneven lengths. This creates waste and makes your product look unprofessional.

An automatic hot knife ribbon webbing cutter2 is a programmable cutting machine that uses heat to cut and seal synthetic webbing1 or ribbon, preventing fraying and ensuring consistent results.

Let me show you why it’s essential for factories working with synthetic materials like nylon or polyester straps.

Why Use an Automatic Hot Knife Webbing Cutter?

Manual cutting tools and scissors can’t handle synthetic materials properly. They leave fibers exposed. Workers waste time cleaning up rough edges.

An automatic hot knife webbing cutter uses a heated blade to cut synthetic webbing1, sealing the edges as it cuts.

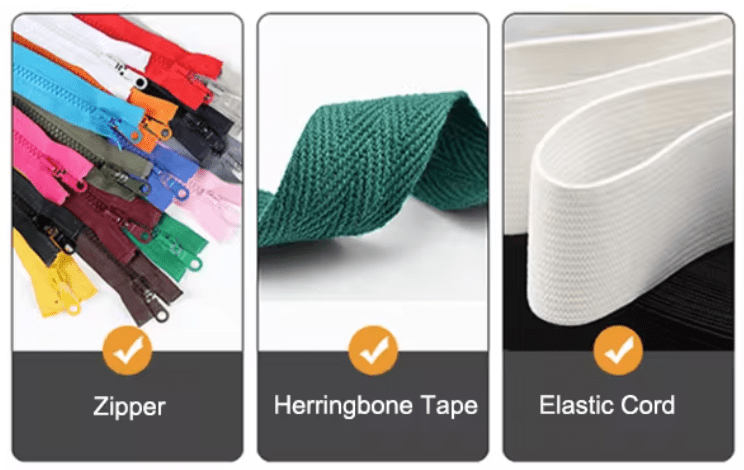

This is perfect for materials like:

- Nylon ribbon

- Polyester webbing

- Seatbelt fabric

- Woven straps

- Elastic bands with synthetic blends

Common Applications

| Industry | Use Case |

|---|---|

| Automotive | Seatbelt and safety strap production |

| Outdoor Gear | Tent straps, backpack webbing |

| Packaging | Handle straps, ribbon wraps |

| Apparel | Waistbands, elastic loops |

| Printing | Logo ribbon, heat-cut tags |

In my factory—Suzhou Haoxinhe Electrical Equipment Co., Ltd.—we use this machine daily to help clients in Europe and North America who need sealed, exact-length ribbon or straps.

How Does the Automatic Hot Knife Webbing Cutter Work?

Clients often ask me: how does this actually seal the edges while cutting?

The machine pulls in the material, measures the programmed length, then uses a high-temperature blade to cut and melt the fibers at the same time.

Key Working Steps

Auto Feeding

Servo motors move the material with high precision.Length Measurement

Built-in encoders or sensors measure the exact length based on your settings.Blade Heating

A ceramic heater brings the knife to 300–400°C depending on your material type.Cutting & Sealing

The hot knife slices through and simultaneously melts the edges to prevent fraying.Auto Stop / Repeat

The machine stops after the batch is complete or continues if set to repeat mode.

Key Features of Our Machine

| Feature | Description |

|---|---|

| Hot Knife Blade | Teflon-coated to prevent sticking |

| Adjustable Temp Control | Ideal for different synthetic materials |

| PLC Touchscreen | Easy to operate and customize |

| Batch Counter | Tracks production volume |

| Safety Cover | Protects operator from heat |

We had a client from Canada cutting custom nylon straps for HVAC installations. His old cutter burned the material unevenly. After switching to our automatic hot knife ribbon webbing cutter2, he reported smoother edges and reduced complaints by 50%.

Why Choose Haoxinhe’s Hot Knife Cutter?

There are many machines on the market, but not all offer the same precision and durability.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we build heavy-duty, customizable hot knife webbing cutters tailored for industrial use.

Our HAOXINHE hot knife cutting machine handles:

- Webbing up to 100mm wide

- Batch sizes of up to 9,999 pieces

- Continuous cutting for long runs

- Optional round blade attachment

- Material detection and auto-stop safety

We serve clients in industries such as:

- Printing and branding (label ribbons)

- Industrial manufacturing (tie-down straps)

- Medical equipment (synthetic elastic)

- Sportswear (waistbands, webbing)

You can request a demo video or even send us your material. We’ll test it in our lab and send back the cutting sample.

Custom Options We Offer

| Custom Part | Benefit |

|---|---|

| Special Blade Design | For thicker or multi-layer webbing |

| Dual Knife Head | Switch between cold and hot blade |

| Auto Labeling | Add printed labels during cutting |

| Adjustable Feed Rollers | For stretch or textured ribbon |

We understand that every factory is different. That’s why we engineer machines to match your exact material and volume requirements.

Conclusion

An automatic hot knife ribbon webbing cutter2 gives you precise, sealed-edge cuts every time. It’s a must-have for synthetic material production lines.

Insights:

An automatic hot knife ribbon webbing cutter2 is a machine that feeds, measures, and cuts synthetic webbing1 or ribbon using a heated blade. It seals the edges while cutting, preventing fraying and ensuring clean results. This machine is ideal for nylon straps, polyester belts, seatbelts, and other synthetic fabrics. At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we offer industrial-grade hot knife webbing cutters with customizable features for different applications. Whether you’re in automotive, printing, or outdoor gear manufacturing, this tool increases efficiency and improves your product quality.