What Is a Foam Cutting Machine?

I used to spend hours cutting foam by hand—uneven edges, wasted materials, frustrated clients.

A foam cutting machine automates the process, giving you faster, cleaner, and more precise cuts.

A foam cutting machine is designed to deliver precise cuts across foam types like EPS, XPS, and sponge, using methods such as hot wire, blades, or waterjets. Options include manual tools and CNC machines for automated, high-accuracy results. Hot wire cutters excel with polystyrene, while CNC foam cutters handle complex 2D/3D designs. Digital cutters use oscillating blades for clean finishes, and manual saws suit smaller or flexible jobs. Choosing the right foam cutter depends on material type, design complexity, and production needs, making it essential for industries like packaging, architecture, and insulation.

This tool changed my workflow. Now I get consistent results with zero guesswork.

How Does It Work and What Can It Be Used For?

I used to think all foam cutters were the same. That’s not true—and it cost me.

Foam cutting machines use heat, blades, or lasers to shape foam. You can cut packaging, insulation, crafts, and industrial parts.

Let’s see how this machine really works and what it can do for your business.

Dive deeper: How Foam Cutting Machines Work

Foam cutting machines come in many types. Each uses a different method to slice through foam accurately:

1. Hot Wire Foam Cutters

This machine heats a wire that slices through foam like butter. It’s best for:

- EPS (expanded polystyrene)

- XPS (extruded polystyrene)

The wire melts the foam, leaving smooth, sealed edges. These machines are simple, low-cost, and ideal for cutting insulation or signage boards.

2. Laser Foam Cutters

These use a high-energy laser beam. They work great for:

- Thin foam sheets

- Foam letters and patterns

- Detailed design work

Lasers don’t touch the material, reducing physical damage. They provide clean cuts with intricate detail, especially for custom projects.

3. CNC Foam Cutters

CNC cutters use computer-guided blades. They’re ideal for:

- EVA, PU, and PE foam

- Custom packaging inserts

- Foam molds and gaskets

You can upload a CAD file, and the machine follows exact coordinates. This gives you excellent control and repeatability for large batches.

4. Automatic Punching or Bevel Cutting Machines

These are advanced cutters that perform cuts with added features like:

- Shape punching

- Angle or bevel cutting

- Complex edge shaping

Machines from Suzhou Haoxinhe Electrical Equipment Co., Ltd. include automatic punching cutting machines, rotary bevel cutting machines, and different shapes cutting machines. These are ideal when you need specialty forms or industrial-scale production.

What Can Foam Cutting Machines Be Used For?

I discovered many industries need precise foam shaping. Here’s a breakdown:

| Industry | Common Uses |

|---|---|

| Packaging | Custom inserts, protective foam layers |

| Construction | Insulation panels, noise barriers |

| Craft & Decor | Signage, models, DIY art pieces |

| Automotive | Soundproofing, seat padding |

| Medical/Pharma | Clean foam trays, sensitive equipment holders |

| Electronics | Shock-resistant packaging for fragile goods |

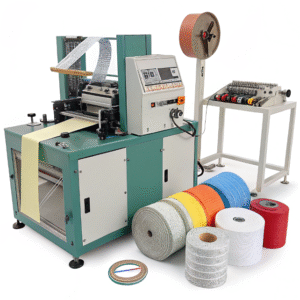

Suzhou Haoxinhe offers cutting solutions for all of these. Their protective foam cutting machines and webbing ribbon cutting machines support high-volume industrial cutting needs. These machines are customizable and made for factories like mine.

When I first sourced from them, their ability to customize foam cutting dimensions saved me money and improved my production quality.

Conclusion

Foam cutting machines use heat, blades, or lasers to create clean shapes for packaging, insulation, or industry-specific needs.

Insight: Foam Cutting Machines Are Not One-Size-Fits-All

In my 20 years working with manufacturing and packaging clients, the most common misconception I’ve seen is assuming any foam cutter will do the job. The truth is, your material, cut complexity, and production volume should drive the machine choice. A hot wire is great for basic insulation panels, but a disaster for custom EVA inserts. CNC excels at repeatability, but fails fast if you’re just prototyping. That’s why suppliers like Suzhou Haoxinhe stand out—they don’t just sell machines, they tailor solutions to your foam type and business goals. That’s the difference between just cutting foam—and cutting waste, time, and cost.

If you’re sourcing in bulk for foam cutting solutions, Suzhou Haoxinhe Electrical Equipment Co., Ltd. has you covered—from hot wire and CNC to specialty shape cutters. Their B2B-focused factory serves markets in Europe, North America, and Asia with top-quality, customizable equipment.