What Is a Bubble Wrap Cutting Machine and Who Should Use One?

Still cutting bubble wrap by hand? It’s time to rethink how you protect your products.

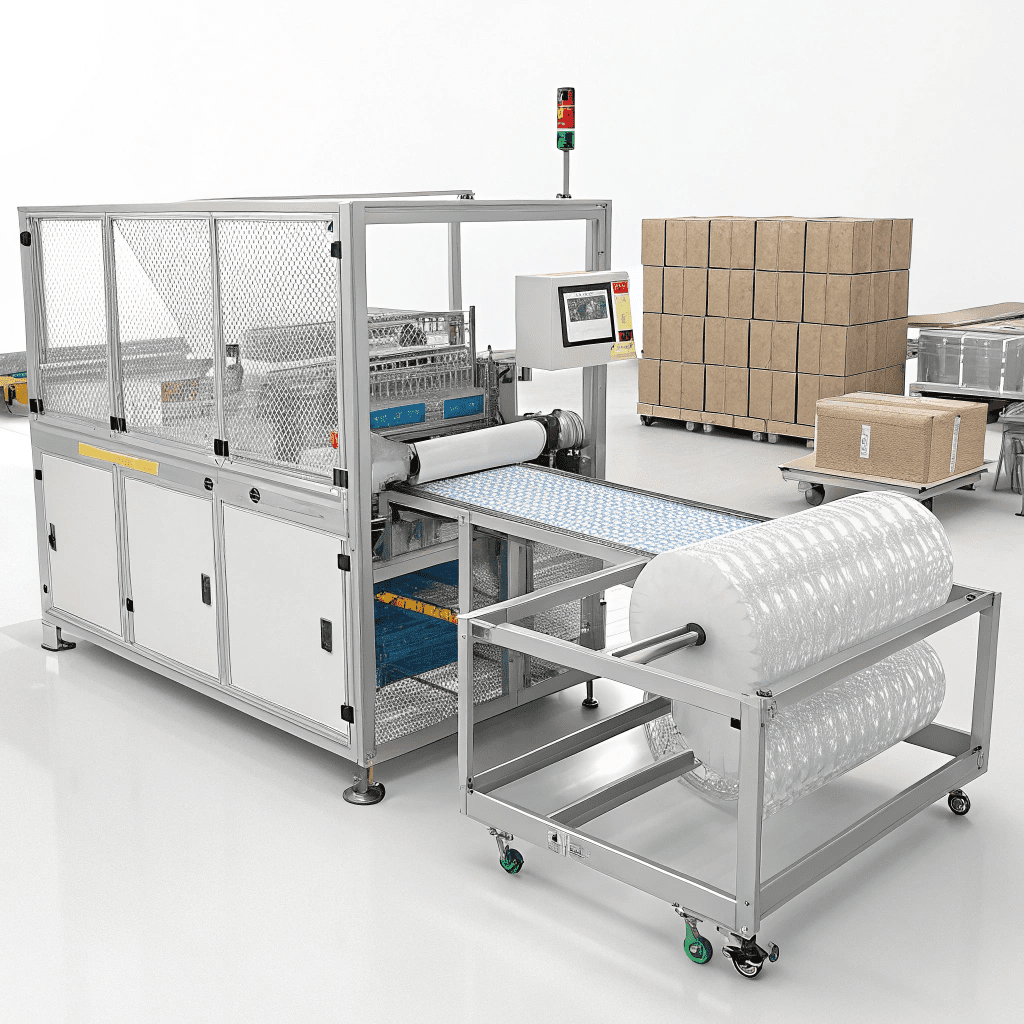

A bubble wrap cutting machine is an automated tool that feeds and cuts bubble wrap to precise lengths — making packaging faster, cleaner, and more efficient.

A Bubble Wrap Cutting Machine is a specialized device designed to efficiently dispense and cut bubble wrap material into usable sheets or smaller pieces, replacing inefficient manual methods like scissors or box cutters.

Let’s break down how it works, what it does, and who needs one the most.

What is a bubble wrap cutting machine?

Manual cutting with scissors or box knives is time-consuming and inconsistent.

A bubble wrap cutter automates the entire process — pulling bubble wrap from a roll, cutting it to an exact length, and dispensing it for immediate use.

Core Components

| Part | Function |

|---|---|

| Feed Rollers | Pull wrap from the roll evenly |

| Length Sensor | Measures sheet to preset size |

| Blade | Cuts wrap cleanly (cold or hot options) |

| Touchscreen Interface | Programs length, speed, and batch settings |

| Output Tray | Collects pre-cut wrap sheets |

You load the roll, set the length, and press start — the machine handles the rest.

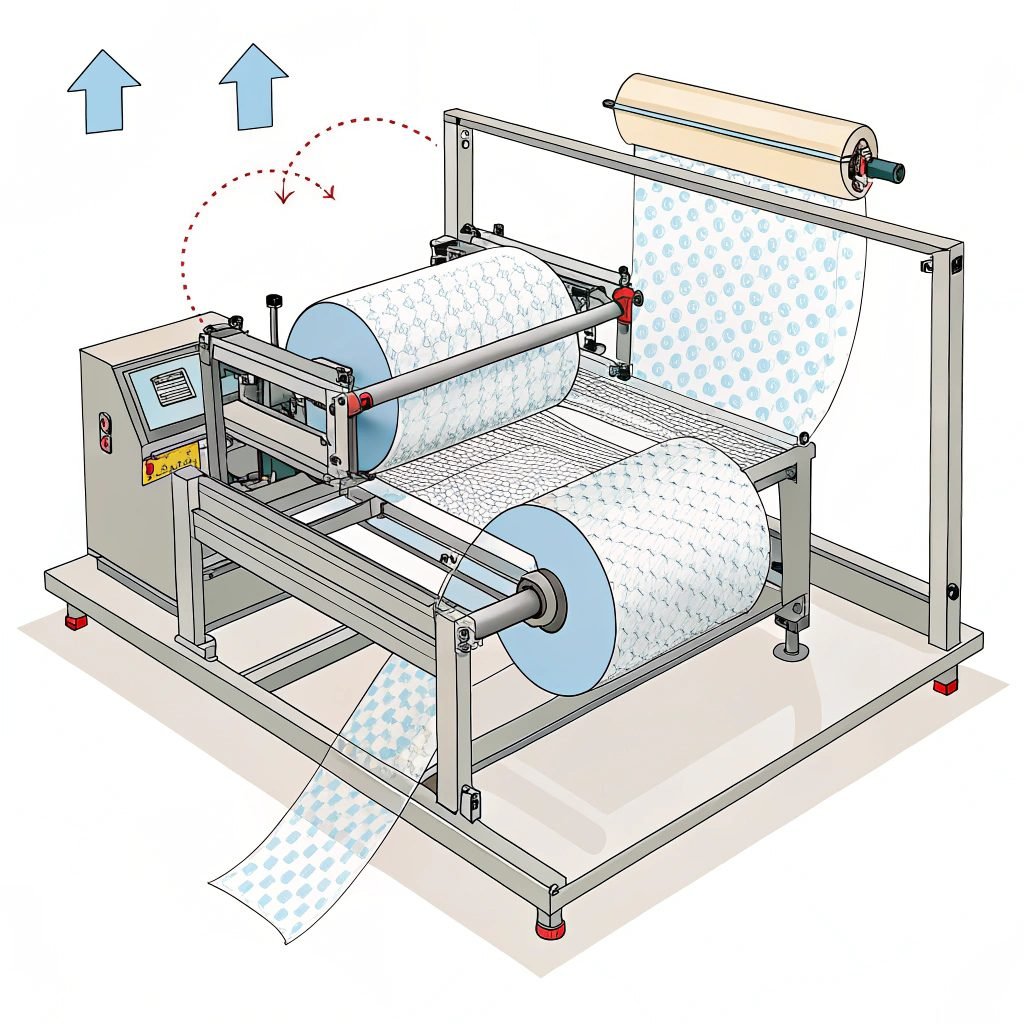

How does it work?

Operation is simple, but powerful.

Once the machine is set up, it continuously feeds the bubble wrap, cuts it to size, and drops sheets ready for packing — with accuracy up to ±1mm.

Step-by-Step Process

- Load roll onto rear shaft

- Set desired length and quantity on touchscreen

- Machine pulls wrap to exact size

- Internal blade cuts cleanly

- Cut sheet drops to bin, tray, or conveyor

- Repeat for next sheet — automatically

Output speed ranges from 5 to 15 sheets per minute, depending on material and settings.

Who should use a bubble wrap cutting machine?

If you package fragile or high-value goods, and use bubble wrap daily — this machine is for you.

It’s perfect for businesses that need consistent, high-speed protective packaging with minimal waste and labor.

Best Fit Industries

| Industry | Why It’s Useful |

|---|---|

| Electronics | Wraps tablets, circuit boards, accessories |

| Furniture | Covers panels, corners, and painted surfaces |

| Appliances | Protects glass doors, controls, and screens |

| Glass & Ceramics | Ensures scratch-free, break-proof transit |

| 3PL & Fulfillment | Speeds up high-volume order packing |

| Medical Equipment | Keeps devices and kits safe during shipment |

Whether you wrap 100 items/day or 1,000, this machine saves time, money, and materials.

What problems does it solve?

Manual cutting leads to material waste, bottlenecks, and packaging inconsistency.

A bubble wrap cutter solves these problems by bringing speed, accuracy, and standardization to your packaging process.

Manual vs Automated Comparison

| Factor | Manual Cutting | Machine Cutting |

|---|---|---|

| Time per Sheet | 30–60 sec | 4–6 sec |

| Labor Required | 2 workers | 1 operator |

| Wrap Waste | 15–25% | <5% |

| Cut Consistency | Inconsistent | ±1mm precision |

| Training Needed | High | Low — touch panel guided |

That’s why it pays off quickly — most factories see ROI in 3–6 months.

What types of bubble wrap can it cut?

Not all bubble wrap is the same — and the right machine handles multiple wrap types without jamming or crushing.

Haoxinhe’s machines support a wide range of protective films and wrap materials.

Supported Materials

| Type | Supported |

|---|---|

| Standard PE Bubble Wrap | ✅ |

| Large-Cell Bubble Wrap | ✅ |

| Anti-Static Bubble Wrap | ✅ |

| Foam-Backed Wrap | ✅ |

| Recycled or Eco-Friendly Wrap | ✅ |

Choose from cold-cut, hot-cut, or perforation options, depending on your product and packaging style.

Key features to look for

If you’re buying a cutter, don’t just look at the price — make sure it fits your workflow and material needs.

Must-Have Features

- 🖥️ Touchscreen with programmable length

- ⚙️ Adjustable speed and batch modes

- 🔪 Replaceable cold or hot blade

- 🧠 Memory presets for common products

- 🧺 Output options: tray, bin, or conveyor

- 🔒 Safety stops and easy maintenance access

All Suzhou Haoxinhe models include these features — designed for continuous factory use.

Why choose Suzhou Haoxinhe?

We specialize in cutting automation — and we build machines to match your needs, not just standard specs.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a CE/ISO-certified manufacturer supplying high-speed, precision cutters worldwide.

Why Clients Choose Us

- Speeds: Up to 10,000 cuts/day

- Cut Lengths: 200mm–3000mm+

- Roll Widths: 300mm to 1500mm

- Cold, Hot, and Perforation Cutting Options

- Touchscreen Control + Memory Presets

- Spare Parts and Remote Training Included

- Global Delivery in 7–15 Days

We also offer:

- Velcro dot cutting machines

- Label, foam, and PVC cutters

- Webbing ribbon and edge banding machines

Used in Europe, North America, Southeast Asia, and beyond by leading manufacturers and 3PLs.

Conclusion

A bubble wrap cutting machine gives you speed, accuracy, and efficiency — helping you protect products better while reducing cost and waste. If you use bubble wrap daily, it’s time to upgrade your tools.

Insights

A bubble wrap cutting machine automates the process of cutting protective film to precise lengths, improving speed, consistency, and material savings. Suzhou Haoxinhe’s machines are ideal for manufacturers, logistics teams, and fulfillment centers that value efficient, professional packaging.