What Innovations Are Improving Accuracy in PVC Sheet Cutting Machines?

Traditional PVC cutting methods often struggle with material deformation and inconsistent cuts.

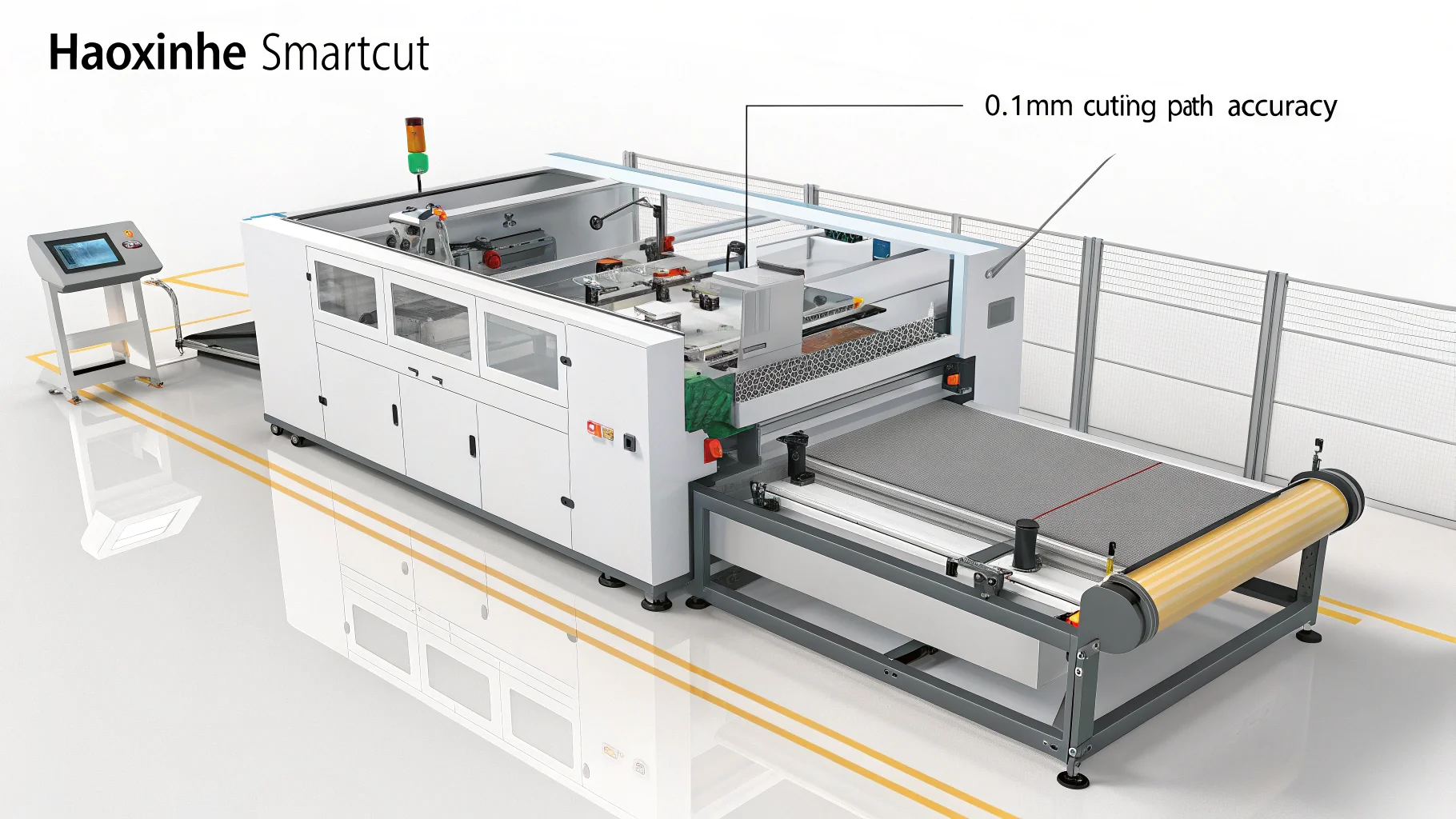

Recent innovations like laser-guided positioning1, AI-powered vision systems2, and dynamic pressure control3 are revolutionizing PVC sheet cutting accuracy. These technologies achieve precision within 0.1mm while compensating for material variations.

How to Select a PVC Sheet Cutter for High-Temperature or Rigid Materials?

Cutting heat-resistant or rigid PVC requires special considerations to avoid poor finishes and tool damage.

For demanding applications, look for machines with temperature-resistant blades4, advanced cooling systems, and material-specific clamping technology. The right combination prevents warping and ensures clean edges.

Key Features for Challenging PVC Materials

| Material Type | Recommended Features | Benefits | Ideal Machine Type |

|---|---|---|---|

| High-Temp PVC | Ceramic-coated blades Liquid cooling system Heat-resistant guides | Prevents softening Maintains blade sharpness Consistent cut quality | Hydraulic beam cutter |

| Rigid PVC | High-torque servo motors Multi-point clamping Vibration dampening | Clean cuts without chipping No material shifting Smooth operation | CNC router cutter |

| Glass-Filled PVC | Diamond-tipped blades Automatic speed adjustment Vacuum worktable | Extended blade life Optimized cutting speed Secure material hold | Plasma cutting system |

Cutting Solutions for Different PVC Grades

Advanced Blade Technologies

- Tungsten carbide edges for extended durability

- Self-sharpening mechanisms for consistent performance

- Temperature-responsive blade angles

Material Handling Systems

- Precision rollers for thick sheet feeding

- Anti-static devices for clean cutting environments

- Automatic thickness detection

Cooling and Support Solutions

- Integrated air cooling for high-temp applications

- Adjustable support grids for rigid sheets

- Laser measuring for real-time compensation

Case Example:

A solar panel components manufacturer using our PVC cutting system achieved:

- Perfectly square cuts on 10mm rigid PVC

- Zero thermal deformation in continuous operation

- 30% faster production through automated material handling

Conclusion

Modern PVC cutting machines combine intelligent monitoring with specialized tooling to handle any material specification – eliminating waste and rework in demanding industrial applications.

Insights from HAOXINHE

Through 20 years of serving PVC product manufacturers, we’ve learned that material-specific cutting solutions make all the difference. Our SmartCut™ technology automatically adjusts 12 cutting parameters based on real-time material analysis – because no two PVC sheets behave exactly alike. This adaptive approach delivers perfect cuts from the first piece to the last.

Innovations improving accuracy in PVC sheet cutting machines primarily revolve around advanced automation, smart technology integration, and precision mechanical design:

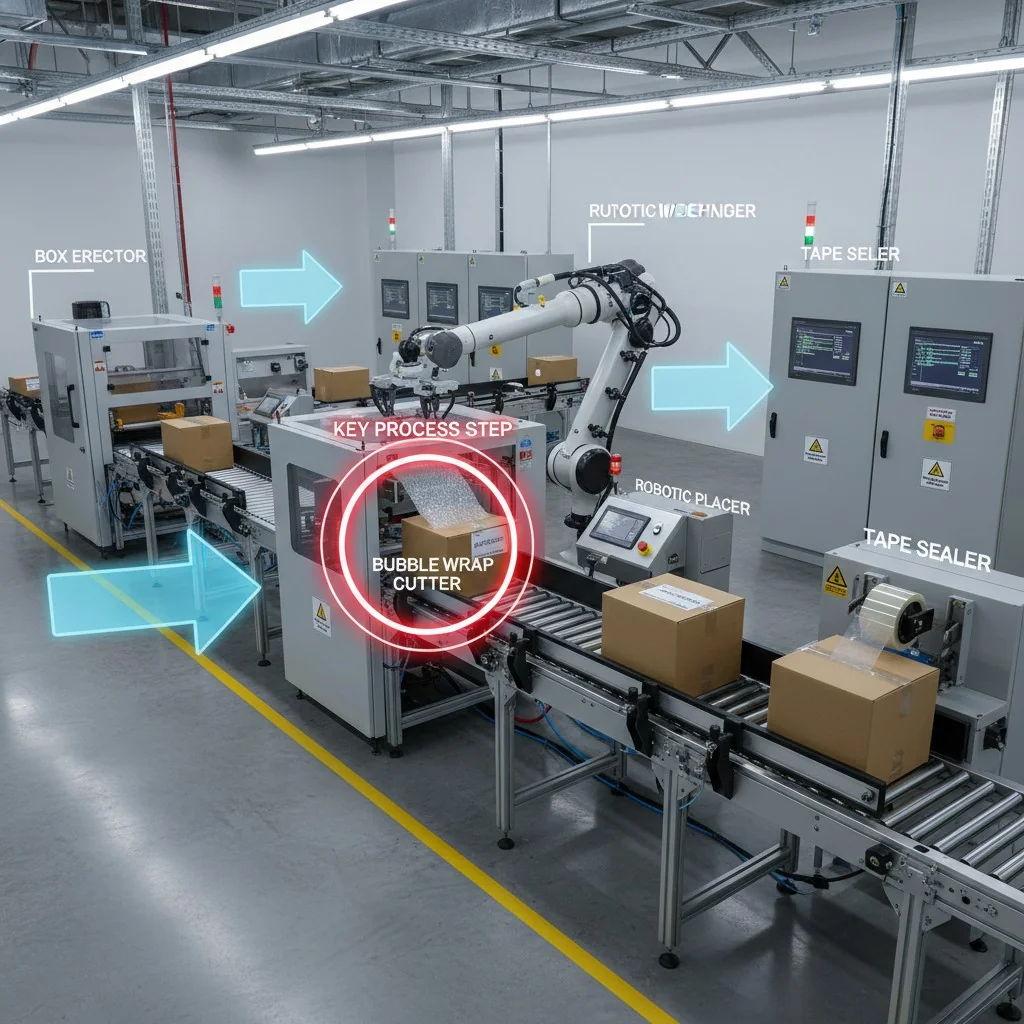

Smart Automation with AI and IoT: Modern PVC sheet cutting machines increasingly incorporate artificial intelligence (AI) and Internet of Things (IoT) technologies. These enable real-time monitoring, adaptive control, and predictive maintenance, which collectively enhance cutting precision and reduce errors during operation.

Robotics and Servo Motor Control: The use of robotics and servo motors provides highly precise and consistent blade positioning and speed control, improving cut quality and uniformity across sheets. Servo motors help maintain exact feed rates and blade pressure adapted to different PVC thicknesses.

Digital Cutting Technology: Digital cutting systems use computer numerical control (CNC) to follow programmed cutting patterns with micron-level accuracy. This automation ensures every cut is replicable and accurate, reducing material waste and operator error.

Explore how laser-guided positioning enhances cutting accuracy and efficiency in PVC sheet cutting. ↩

Learn about the role of AI in achieving precision and reducing errors in PVC cutting processes. ↩

Discover how dynamic pressure control contributes to consistent cuts and material handling. ↩

Understand the significance of temperature-resistant blades in maintaining cut quality for high-temp PVC. ↩