What Do You Use to Cut Nylon? How Do You Keep Nylon Webbing From Fraying?

Cutting nylon sounds simple—until you see frayed, fuzzy edges and uneven cuts that ruin your product. The wrong tools turn strong nylon into weak waste.

To cut nylon cleanly, use a hot knife, rotary blade, or heat-integrated cutting machine. To prevent fraying, always seal the edges with heat right after cutting.

I’ve helped dozens of industrial buyers solve this exact problem—and trust me, it’s all about heat, precision, and the right machine.

What Do You Use to Cut Nylon?

Most people try scissors or box cutters—and they get fraying and stretched webbing. That’s because nylon is synthetic and reacts poorly to friction and cold cuts.

The best tools to cut nylon are hot knives, heated blades, or automatic webbing tape cutting machines with heat sealing functions.

Top 3 Nylon Cutting Methods

| Tool / Machine | Best For | Pros | Cons |

|---|---|---|---|

| Hot knife | Small runs, manual cuts | Seals edges instantly | Slower, manual process |

| Rotary cutter + heat sealer | Thin nylon or fabric layers | Cleaner lines, better control | Extra sealing step needed |

| Hot and cold cutting machine | Mass production (e.g. webbing, foam) | Speed + edge sealing in one step | Higher initial investment |

My Experience in Production

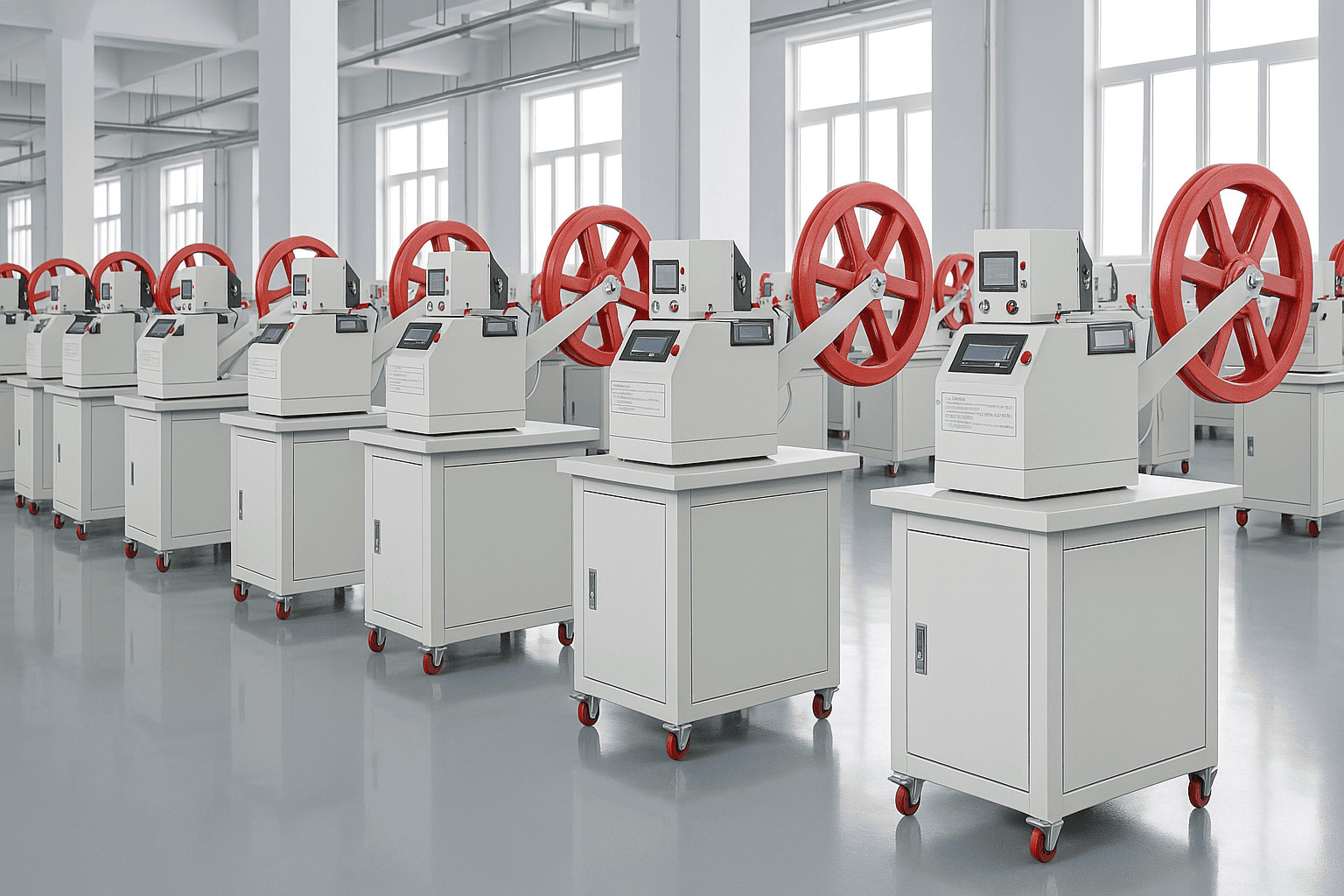

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we manufacture:

- Hot and cold cutting machines for nylon and PVC

- Webbing tape cutting machines with programmable precision

- Rotary bevel cutting machines with integrated heat modules

These are widely used in:

- HVAC and construction straps

- Protective foam packaging

- Bubble wrap strips

- Medical-grade webbing

Whether it’s for PVC edge banding or thick webbing rolls, heat makes the difference.

How Do You Keep Nylon Webbing from Fraying?

Nylon webbing is woven from slippery fibers. When cut cold, the threads instantly start to unravel, especially during heavy use.

To keep nylon webbing from fraying, seal the edges using heat—through a hot knife, flame, or an automated heat-cutting system.

4 Reliable Ways to Prevent Fraying

1. Use a Hot Knife

Manually slice through and seal the edges at the same time.

- Ideal for: Small batches, field work

- Clean, strong results

2. Flame Seal the Edges

Cut cold first, then quickly pass a lighter over the edge.

- Cheap and fast

- Risk of uneven melting

3. Use a Heated Cutting Machine

Industrial-grade option—automates cut + seal process.

- Our automatic punching cutting machine integrates hot blade sealing

- Great for webbing, ribbon, and synthetic foam

4. Add Edge Binding

Less common, but used in high-end straps or gear

- Involves sewing or wrapping the edge

- More labor-intensive

Why Fraying Is More Than Just Ugly

Fraying causes:

- Weak strap performance

- Difficulty inserting through buckles or hardware

- Increased product returns or customer complaints

That’s why buyers sourcing from China often ask us: “Do your machines seal the edge?” And we always say: Yes—with programmable heat and speed controls.

Our webbing tape cutting machines have:

- Temperature control up to 400°C

- Cold cut / hot cut switchable modes

- Servo motor accuracy within ±0.1mm

This ensures clean, fray-free results even at 150 cuts/min.

Conclusion

You can cut nylon using hot knives or machines—but only heat will stop it from fraying. The right cutting tools not only improve quality, they reduce rework and returns.

Insights

To cut nylon cleanly and avoid fraying, always use a hot knife or heat-integrated cutting machine. Cold cuts lead to unraveling. Suzhou Haoxinhe Electrical Equipment Co., Ltd. provides high-precision webbing tape cutting machines and hot and cold cutting systems that seal edges instantly. Our solutions are trusted by industrial clients working with nylon, PVC edge banding, foam, and bubble wrap materials across Europe, North America, and Asia.

Meta Description

Discover the best tools to cut nylon and how to stop nylon webbing from fraying. Learn how Suzhou Haoxinhe machines ensure clean, sealed edges with every cut.