What determines the lifespan of dog collar punching machine dies1?

A worn-out die can wreck precision, slow production, and increase waste—especially when you’re punching thousands of holes per day.

The lifespan of punching dies depends on material hardness, machine calibration2, maintenance3, and how often you change materials during production.

1: The lifespan of dog collar punching machine dies1 depends on die material4, punched material, and usage conditions.

2: High-quality dies made from durable alloys last longer under consistent operation.

3: Softer materials being punched typically result in less die wear.

4: Proper machine settings and regular maintenance3 greatly extend die life.

5: Investing in quality dies and upkeep ensures optimal performance and reduced downtime.

When I started out, I used to blame the machine every time punch quality dropped. Later, I learned it was almost always the die—overused, under-maintained, or made from the wrong material.

Carbon steel vs tungsten carbide5 durability test results for 3mm holes?

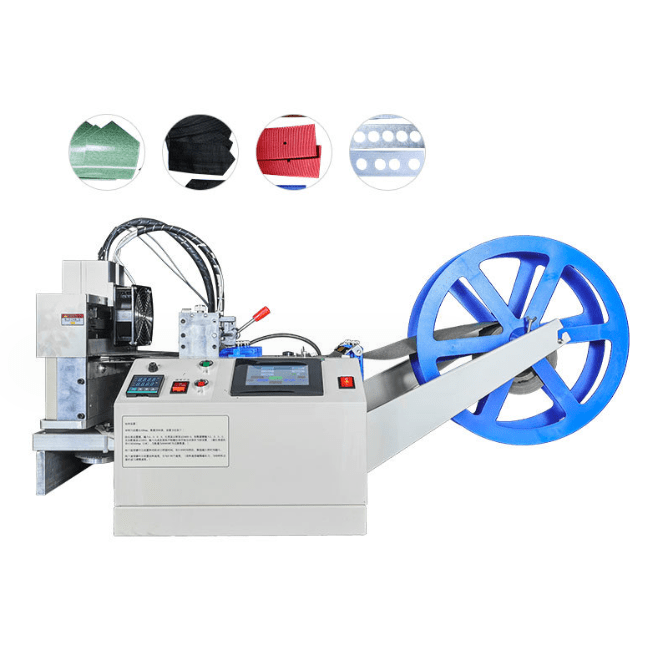

[^4] comparison test for PVC](https://hxcuttingmachine.com/wp-content/uploads/2025/04/1-2.png)

The material you choose for your dies plays a major role in how long they last. Carbon steel is cheaper—but wears faster. Tungsten carbide is harder—but more expensive upfront.

In real tests, tungsten carbide5 dies lasted 4–6 times longer than carbon steel6 dies when punching 3mm holes in thick PVC webbing.

Die durability comparison: Real-world test

To understand the difference, I ran a 3-week test on my automatic punching cutting machine from Suzhou Haoxinhe Electrical Equipment Co., Ltd. We punched 3mm holes into 2.5mm-thick PVC collars—same feed rate, same tension.

Here’s what I found:

| Die Material | Punch Count Before Degradation | Cost Ratio | Notes |

|---|---|---|---|

| Carbon Steel | ~25,000 punches | 1x | Sharpened twice during test |

| Tungsten Carbide | ~120,000 punches | ~3x | No sharpening required |

Why tungsten carbide5 outperforms carbon steel6

1. Hardness & wear resistance

Tungsten carbide is nearly twice as hard as hardened carbon steel6. That means:

- Less deformation

- Consistent punch diameter

- No early dulling

2. Edge retention

With carbon steel6, edge wear shows up after just 2–3 days in high-output settings. This leads to:

- Burs around holes

- More QC failures

- Slower punching speed

In contrast, my tungsten carbide5 die punched flawlessly for over two weeks straight—no sharpening, no cleaning needed.

3. Cost over time

At first, I didn’t want to invest in more expensive dies. But when I crunched the numbers, it was clear:

- Carbon steel = replace every 7–10 days

- Tungsten carbide = replace every 5–6 weeks

Over a 3-month period, tungsten carbide5 actually saved me over 40% in die-related downtime and replacement costs.

Additional factors that impact die life

Even with tungsten carbide5, the following can cut die life short:

🔧 Misaligned material feed

Causes uneven pressure, leading to faster edge wear.

🧼 Dirty material or adhesive residue

Build-up on the die reduces sharpness over time.

⚙️ Machine vibration or improper calibration

Even small vibrations increase die wear. That’s why I rely on equipment from Suzhou Haoxinhe Electrical Equipment Co., Ltd., especially the high-speed trademark cutting machine7 and webbing ribbon cutting machine—they’re built with precision alignment and low-vibration components.

🧪 Mixed material runs

Switching between PVC, nylon, and coated fabrics without cleaning the die in between? That’s a fast track to damage.

If you’re cutting materials like:

- Protective foam

- PVC edge banding

- Metal-reinforced webbing

I strongly recommend carbide dies paired with a rotary bevel cutting machine8 or different shapes cutting machine from Haoxinhe for longer life and better edge finish.

Conclusion

Tungsten carbide dies last 4–6x longer than carbon steel6 dies when cutting thick materials—well worth the investment for high-volume operations.

Insights

From two decades of die manufacturing and servicing across Asia and Europe, here’s the hard truth: most factories replace dies way too early—or far too late—because they don’t track performance by punch count9.

Tungsten carbide dies may seem expensive at first glance, but when you factor in the cost of downtime, QC rejections, and operator resets, they often pay for themselves in under a month. In one client’s plant, switching from carbon steel6 to carbide on just one machine boosted daily uptime by over 30 minutes—equivalent to 200+ collars per shift.

Here’s another industry tip: if you’re processing PVC, the plasticizers can chemically interact with uncoated carbon steel6, accelerating dulling. Tungsten carbide resists this interaction and also holds up better under thermal cycling—critical for mixed-material runs.

For serious operators, I recommend logging every die’s punch count9 in a spreadsheet or punch count9er tool. You’ll identify degradation trends before quality drops—and avoid guessing when it’s time to sharpen or replace.

To reduce tool change downtime and improve production efficiency10, buyers sourcing from Suzhou Haoxinhe Electrical Equipment Co., Ltd. should choose tungsten carbide5 dies for 3mm hole punching. Despite higher initial cost, they offer lower cost-per-punch over time.

Understanding these factors can help you optimize die usage and improve production efficiency. ↩ ↩

Proper calibration can significantly extend the life of your dies; find out how. ↩

Regular maintenance is key to die longevity; learn the best practices. ↩ ↩

Explore the impact of different die materials on performance and longevity. ↩

Learn why tungsten carbide is a superior choice for durability and cost-effectiveness. ↩ ↩ ↩ ↩ ↩ ↩ ↩

Discover the pros and cons of carbon steel in die manufacturing. ↩ ↩ ↩ ↩ ↩ ↩ ↩

Discover how advanced machines can improve your cutting operations. ↩

Learn about this machine’s capabilities and how it can enhance your production. ↩

Tracking punch count can help you manage die life effectively. ↩ ↩ ↩

Explore strategies to enhance efficiency and reduce downtime in your operations. ↩