What cutting accuracy can you expect from a bubble wrap cutter?

Factories often lose profit because cuts are inconsistent. Too short, and packaging doesn’t fit. Too long, and material is wasted.

Modern bubble wrap cutting machines deliver ±1–2 mm accuracy, depending on model class and encoder resolution used in the feeding system.

- Professional Precision: Bubble wrap cutters1 deliver clean, consistent cuts far superior to manual tearing or scissors.

- Accuracy Levels: Automatic machines2 offer high precision with error margins as low as ±1mm, ideal for industrial use.

- Manual Cutters: Dispensing stand cutters ensure straight, repeatable cuts in warehouse and shipping settings.

- Efficiency Upgrade: Precision cutting reduces material waste and speeds up packaging operations.

- Choose Based on Need: Select between manual or automated cutters based on volume, accuracy, and workflow requirements.

If you’re sourcing from Alibaba or exhibitions, you’ll notice accuracy claims everywhere. Let’s break down what these numbers mean and how encoder technology affects cutting precision.

Acceptable tolerances (±1–2 mm) by model class and how encoder resolution impacts length error

When customers ask about accuracy, most suppliers promise "high precision." But the truth depends on the machine’s model class and its encoder system.

Entry-level cutters typically deliver ±2 mm, while high-end PLC-controlled machines3 with advanced encoders achieve ±1 mm accuracy or better.

Here’s what to expect:

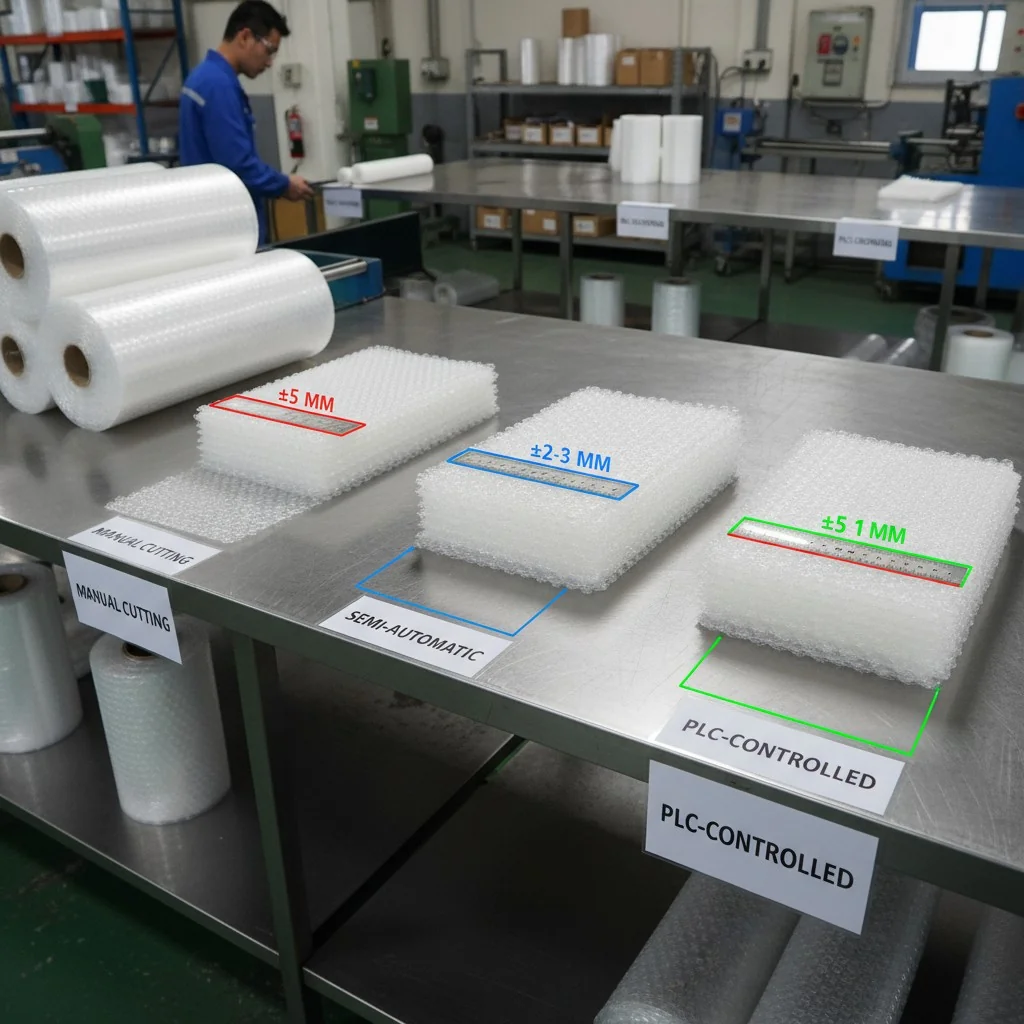

Model Classes & Tolerances

Manual Blade Cutters (basic Alibaba models):

Operator-dependent, tolerance can be ±5–10 mm. Best only for small-volume or non-critical use.Semi-Automatic Cutters (mid-range Chinese/Taiwanese):

Gear-driven feed rollers with basic step counters. Accuracy around ±2–3 mm.Fully Automatic PLC Cutters (HAOXINHE, high-end Alibaba, German brands):

Equipped with servo motors and high-resolution encoders. Accuracy ±1–2 mm, even at high speeds.

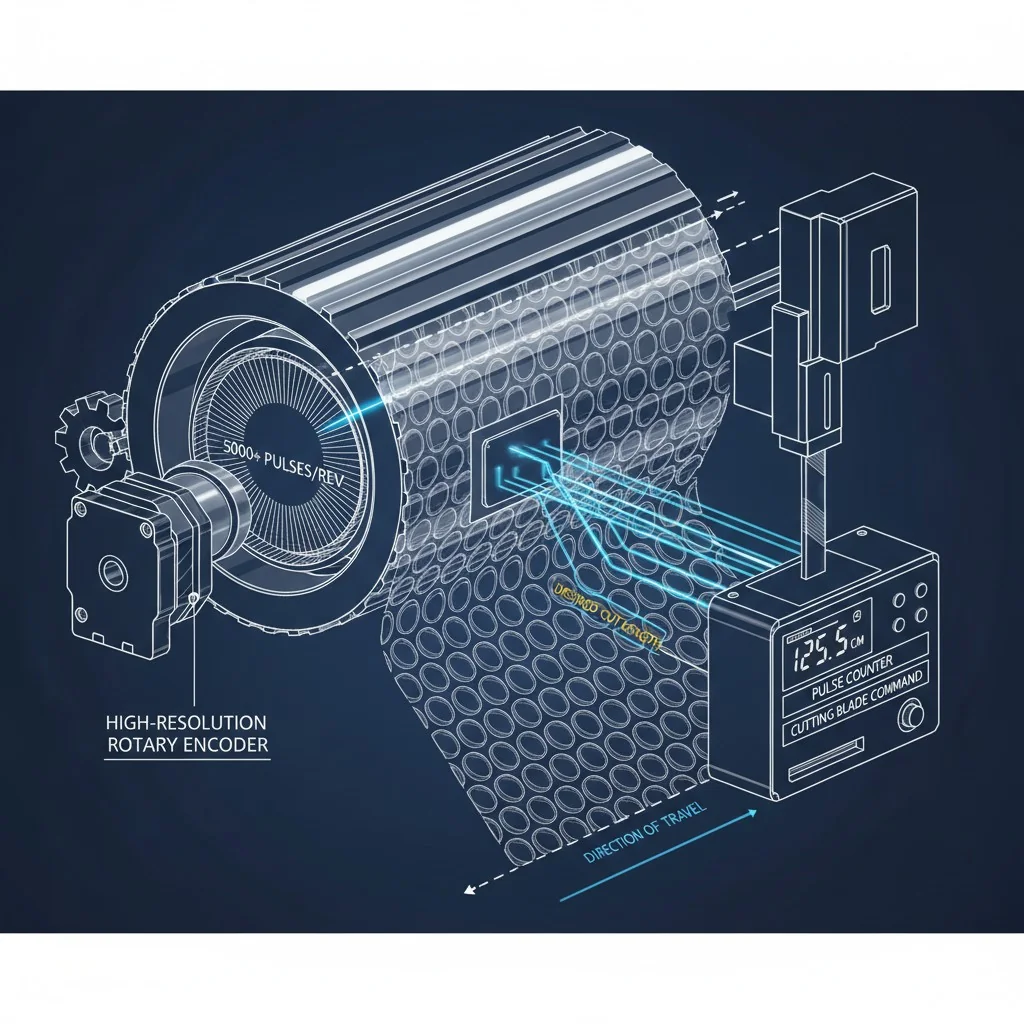

Encoder Resolution & Its Impact

Encoders measure roller movement, ensuring each piece is cut to the programmed length. The higher the resolution, the better the accuracy.

Low-resolution encoders (500–1000 pulses/rev):

Error margin is higher. Length drift may reach ±3 mm on long runs.Mid-resolution encoders (2000 pulses/rev):

Accuracy improves, errors typically within ±1.5–2 mm.High-resolution encoders (5000+ pulses/rev):

Errors reduced to ±1 mm or less. Stable even during continuous duty.

👉 At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our Bubble Wrap Cutting Machine uses PLC control with high-resolution encoders to ensure consistent cuts across thousands of cycles.

Accuracy Table by Class

| Machine Type | Encoder Type | Tolerance (mm) | Notes |

|---|---|---|---|

| Manual Blade Cutter | None | ±5–10 mm | Depends on operator skill |

| Semi-Automatic | Basic step counter | ±2–3 mm | Better but drifts on longer cuts |

| Automatic PLC (Standard) | 2000 ppr encoder | ±1.5–2 mm | Suitable for most industrial packaging |

| Automatic PLC (High-End) | 5000+ ppr encoder | ±1 mm | Best choice for continuous-duty factories |

Real-World Example

One Alibaba buyer from Italy reported their generic mid-range cutter produced up to 4 mm length error after long runs. They switched to a HAOXINHE PLC Hot-Knife Cutter with 5000 ppr encoder, reducing variance to under 1 mm per cut. This saved thousands of meters of bubble film over a year.

Conclusion

The best bubble wrap cutters deliver ±1 mm accuracy4 with high-resolution encoders, while entry-level models may drift by up to ±5 mm.

🧠 Industry Insight: What “±1 mm” Accuracy Really Means in Bubble Wrap Cutting

In the industrial world, ±1 mm might sound minor—but over 30,000 cuts per month, even a 2 mm drift becomes a massive material loss. I’ve seen factories waste entire rolls weekly because their cutter says it’s precise but drifts without warning due to low-resolution encoders or thermal expansion in rollers.

The key differentiator? Encoder resolution + real-time feedback loop. Many budget machines rely on timing or basic stepper motors without feedback. That’s like driving blind at 100 km/h. Top-tier machines (like those from HAOXINHE) use 5000+ pulse encoders with servo-driven rollers, giving real-time length correction—even during high-speed runs.

A customer in the EU logistics sector told me their previous cutter ran fine—until they ramped up to double shifts. Accuracy slipped from ±2 mm to ±6 mm. Why? Heat expansion and no encoder feedback. They upgraded to a HAOXINHE model and cut error variance by 85%.

If you’re not verifying encoder specs during purchase, you’re rolling the dice with your film budget.

Buyers sourcing on Alibaba should check encoder resolution and tolerance specs before choosing a bubble wrap cutting machine. At Suzhou Haoxinhe Electrical Equipment Co., Ltd., our bubble wrap cutting machines, protective foam cutters, and webbing tape cutting machines use PLC systems with high-resolution encoders, delivering ±1 mm precision for continuous industrial production.

Explore how bubble wrap cutters enhance efficiency and precision in packaging operations. ↩

Learn about the advantages of automatic machines for achieving high precision in cutting. ↩

Discover the technology behind PLC-controlled machines and their advantages in precision cutting. ↩

Get insights into the significance of accuracy levels in industrial cutting applications. ↩