What are the two types of cutting machine?

Struggling to choose the right cutting machine for your production line? You’re not alone—many manufacturers face the same confusion.

There are two main types of cutting machines: manual die-cut machines and digital machine cutters. Each has its own advantages and suits different production needs.

If you’re in manufacturing, printing, or packaging, choosing the right cutting machine affects your efficiency, cost, and final product quality. Let’s explore the core differences and when to choose which.

What are the two types of cutting machine?

Many buyers get overwhelmed by technical jargon when choosing cutting equipment.

The two main types are manual die-cutting machines1 and digital cutting machines2.

Manual Die-Cutting Machines

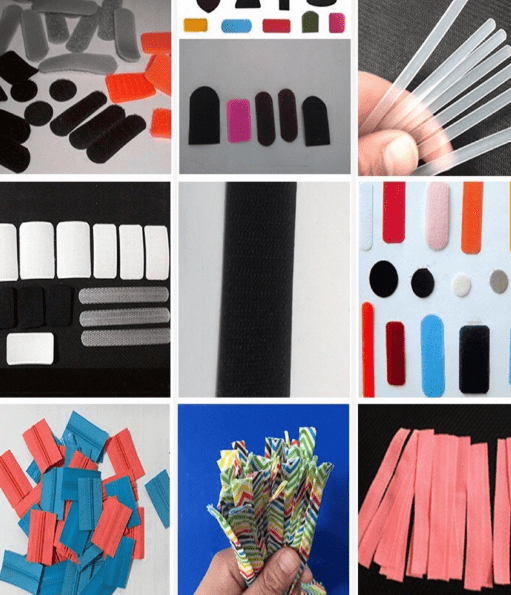

Manual die-cut machines use metal dies to cut shapes out of materials. You insert a die and a material into the machine, then apply pressure—often through a crank or lever—to create the cut.

This type is best for:

- Low-volume tasks

- Repetitive shapes

- Simple cutting jobs

- Materials like paper, vinyl, and felt

Manual machines are cost-effective, compact, and don’t require software. However, they’re less flexible and not suitable for mass production or intricate patterns.

Digital Cutting Machines

Digital or electronic cutting machines use a blade or laser controlled by software. You upload your design file, choose your material, and let the machine do the rest.

They are great for:

- Complex or custom shapes

- High-volume production

- Businesses with changing designs

- Cutting materials like acrylic, leather, fabric, and even metal

They require software skills and more upfront investment. But in return, they offer precision, speed, and flexibility.

Comparison Table

| Feature | Manual Die-Cut Machines | Digital Cutting Machines |

|---|---|---|

| Operation | Manual crank | Software-controlled |

| Flexibility | Low | High |

| Initial cost | Low | Medium to high |

| Best for | Repetitive cuts | Custom, complex cuts |

| Required skill level | Basic | Intermediate |

| Material range | Limited | Wide |

| Maintenance | Low | Medium |

What is the difference between die cut and machine cut?

Cutting terms can be confusing, especially when they overlap in casual conversations.

Die-cutting uses physical dies for shaping materials, while machine cutting refers to digital processes using software-guided tools.

Die Cutting: A Traditional Approach

Die cutting is like using a cookie cutter. A shaped metal die is pressed onto material to create uniform shapes. The die itself is custom-made, which can be expensive but pays off if you make the same shape repeatedly.

Typical use cases:

- Greeting cards

- Labels and stickers

- Packaging inserts

This method is fast and consistent, but lacks flexibility. Every new design requires a new physical die.

Machine Cutting: A Digital Advantage

Machine cutting refers to using digital tools—like a CNC machine or laser cutter—to carve out shapes. Instead of needing a physical die, you use design software to create files. The machine follows this digital guide to make precise cuts.

You can:

- Cut one-off designs without extra tooling

- Edit shapes quickly

- Use one machine for many jobs

It’s ideal for industries that deal with personalization, prototyping, or frequent product updates.

Which One is Better?

That depends on your production style.

- Choose die-cutting if your design never changes and volume is high.

- Choose machine cutting if you need flexibility and precision with complex patterns.

Real-World Use in My Factory

At HAOXINHE, we use both types depending on our clients’ needs. For standardized parts, we rely on die-cutting for speed and cost-efficiency. But when a customer asks for a customized mold or shape, our digital cutting machines2 take over. This dual setup gives us the agility to handle both mass production and one-off, high-precision jobs.

Conclusion

Die-cut and machine-cut methods serve different needs—choose based on your production volume, design complexity, and budget.

Insights:

If you’re sourcing chiller or mold-related equipment and need flexible production options, understanding these cutting methods helps you ask the right questions to your supplier. Always clarify what type of cutting process they use—this can impact your product’s accuracy, cost, and lead time. At HAOXINHE, we’re transparent about our machinery so you always know what you’re getting.