What are the top manufacturers of aluminium foil cutting machines in 2026?

Not all machines are built the same—choosing the wrong brand can lead to downtime, poor cuts, and high repair costs.

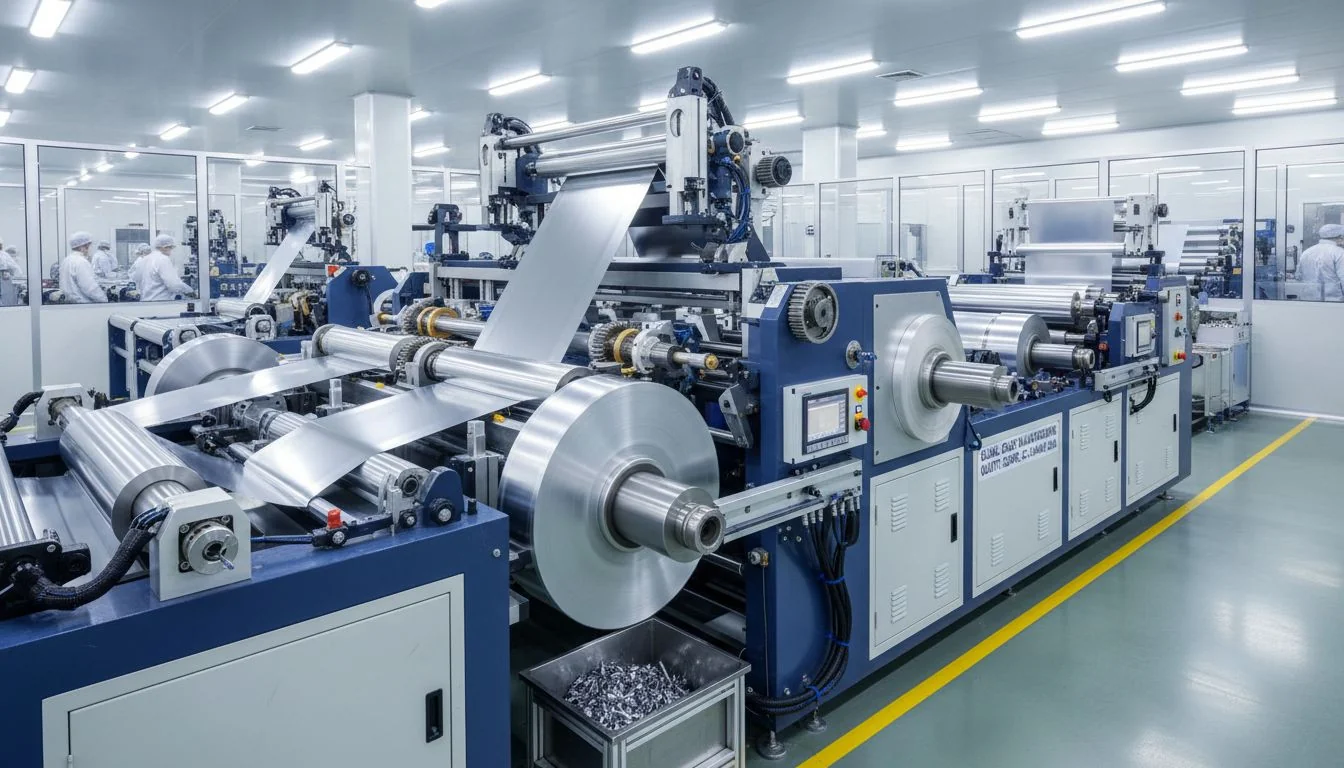

The top aluminium foil cutting machine manufacturers in 2026 include Suzhou Haoxinhe (China), Kampf (Germany), Euromac (Italy), and Nishimura (Japan)—each offering distinct strengths in speed, durability, and pricing.

With hundreds of global suppliers and copycats, it’s hard to know who delivers real industrial performance. Let me help you compare the leading names based on real-world metrics that matter to factories.

How do global brands compare in terms of durability, speed, and price?

High price doesn’t always mean high performance. What matters is the right balance between long-term reliability, cutting output, and cost-efficiency.

Global aluminium foil machine brands vary significantly—European models offer durability, Japanese machines focus on precision, while Chinese manufacturers lead on customization, automation, and pricing.

Let’s look at the comparison across three critical dimensions: Durability, Cutting Speed, and Cost.

🏭 Top Manufacturers in 2026 (with brand specialties)

| Brand Name | Country | Strengths |

|---|---|---|

| Suzhou Haoxinhe1 | China | Custom automation, affordable pricing, strong support |

| Kampf2 Schneid- und Wickeltechnik | Germany | Long lifespan, precision at scale |

| Euromac3 | Italy | Advanced slitting tech, cleanroom designs |

| Nishimura4 Mfg. | Japan | High-precision systems, strong for narrow web foils |

| Elite Cameron5 | UK | Versatile converting lines, moderate volume factories |

| Atlas Converting6 | UK/Italy | Premium systems for wide-web foil and high-volume demands |

⚙️ Performance Comparison by Category

1. Durability

| Brand | Durability Score (1–10) | Notes |

|---|---|---|

| Kampf2 (Germany) | 10 | Industrial-grade build, lifetime >15 years |

| Euromac3 (Italy) | 9 | Clean engineering, stainless components |

| Nishimura4 (Japan) | 9 | Precision parts, low wear rate |

| Haoxinhe (China) | 8 | Durable for price, uses industrial components |

| Elite Cameron5 (UK) | 7 | Lighter-duty but reliable for moderate use |

2. Cutting Speed (Aluminium Foil < 100μm)

| Brand | Max Speed (m/min) | Suitable For |

|---|---|---|

| Haoxinhe (China) | 130–180 | Flexible production, high-volume |

| Kampf2 (Germany) | 150–200 | Full-scale packaging operations |

| Euromac3 (Italy) | 120–160 | Standard speed for commercial packaging |

| Nishimura4 (Japan) | 100–140 | High-precision foil cutting |

| Elite Cameron5 (UK) | 100–130 | Multi-purpose applications |

3. Price (Base Model, 2026)

| Brand | Avg. Price (USD) | Value Notes |

|---|---|---|

| Haoxinhe (China) | $6,000–$18,000 | Best ROI, supports customization + automation |

| Nishimura4 (Japan) | $18,000–$30,000 | Premium precision models |

| Euromac3 (Italy) | $20,000–$35,000 | Ideal for cleanroom or pharma-grade applications |

| Kampf2 (Germany) | $25,000–$45,000 | Long-term investment for large-scale factories |

| Elite Cameron5 (UK) | $12,000–$22,000 | Mid-market solution for converting businesses |

🔍 Why Suzhou Haoxinhe1 is a strong contender

Suzhou Haoxinhe1 Electrical Equipment Co., Ltd. is one of the few B2B-focused factories offering both standard and custom aluminium foil cutting machines for industrial clients. Our popular models include:

- Webbing ribbon cutting machine

- Hot and cold cutting machine

- Protective foam cutting machine

- Rotary bevel cutting machine

- Computer tube cutting machine

We’re able to deliver automation-ready7, servo-motor equipped8 machines with:

- Touchscreen control

- Auto tension adjustment

- Multi-layer cutting support

- CE & ISO certification for export

Our clients in Canada, Germany, France, and Singapore have scaled up production lines using our machines with minimal support needs and low failure rates.

🧪 User Feedback Snapshot (2025–2026)

| Feature | Haoxinhe Score | Kampf2 Score | Euromac3 Score |

|---|---|---|---|

| Customization Flexibility | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

| Support Responsiveness | ★★★★★ | ★★☆☆☆ | ★★★★☆ |

| Export Documentation | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Maintenance Simplicity | ★★★★☆ | ★★★★★ | ★★★★☆ |

| Price-to-Performance | ★★★★★ | ★★★☆☆ | ★★★☆☆ |

Conclusion

Durability, speed, and smart automation define today’s best foil cutting machine brands—choose based on your production goals and not just the name.

🧠 Industry Insights: Choosing Aluminium Foil Cutting Machines in 2026

Having consulted with dozens of packaging factories and OEM buyers across Europe and Asia, one truth has become clear in 2026: machine selection is no longer just about the brand—it’s about the balance between integration, uptime, and after-sale flexibility. While legacy players like Kampf and Euromac continue to dominate with robust mechanical systems, they’re often overbuilt for mid-sized factories or slow to adapt to emerging foil materials and multi-layered applications.

The real disruptor? Suzhou Haoxinhe. With modular automation and strong export readiness, it’s positioned as a smart choice for operations scaling from 2 to 5 lines. Its servo-based systems enable precise control at high speeds, and the built-in PLC interfaces allow seamless integration with ERP and MES systems—something many European models still treat as “custom development.”

Also worth noting: in the sub-$20K segment, Chinese suppliers like Haoxinhe now outcompete many Western brands not just on cost, but on lead time, digital interfaces, and customization (e.g., rotary vs. straight blade, slitting width adjustments, touchscreens in local languages). This is a big win for converters targeting high-mix, low-volume production in markets like personal care, pharma, and specialty foods.

Bottom line: Don’t pay for legacy weight unless your volume justifies it. In 2026, modular, automation-ready machines with local support partnerships are where smart factories are investing.

Explore how Suzhou Haoxinhe stands out in the market with its innovative solutions and customer support. ↩ ↩ ↩

Learn about Kampf’s precision and durability that make it a top choice for industrial applications. ↩ ↩ ↩ ↩ ↩

Discover Euromac’s advanced technology and how it caters to cleanroom and pharma-grade applications. ↩ ↩ ↩ ↩ ↩

Find out why Nishimura is preferred for narrow web foils and high-precision cutting. ↩ ↩ ↩ ↩

Explore the versatility and reliability of Elite Cameron’s solutions for moderate volume factories. ↩ ↩ ↩ ↩

Learn about Atlas Converting’s high-volume demands and wide-web foil capabilities. ↩

Discover how automation can enhance production efficiency and reduce labor costs. ↩

Find out how servo motors improve precision and control in cutting processes. ↩