What are the energy consumption considerations for Velcro cutting machines?

Running industrial cutting machines nonstop can lead to surprisingly high electricity costs.

Modern Velcro cutting machines are designed for energy efficiency, with optimized motors, smart temperature controls, and standby modes that reduce unnecessary power usage.

Velcro cutting machines—especially automated models—are generally built with energy efficiency in mind, but actual power consumption depends on several operational factors.

Key Energy Consumption Factors:

- Cutting speed: Slower speeds may lead to higher energy use due to prolonged operation time.

- Material type: Thicker or tougher Velcro requires more force and energy to cut.

- Machine size and motor capacity: Larger machines with high-powered motors naturally consume more electricity.

- Maintenance: Regular servicing and blade sharpening reduce mechanical strain and optimize energy performance.

- Cutting parameters: Settings like feed rate and depth directly impact energy requirements.

Proper configuration and upkeep can significantly reduce energy consumption, making Velcro cutting machines both cost-effective and environmentally friendly.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we build energy-conscious machines for factories looking to cut both Velcro and operating costs.

How energy-efficient are modern Velcro cutters?

Older machines often overheat or use oversized motors—wasting energy during idle times or low-speed runs.

Most current Velcro cutting machines consume between 0.5–2.5 kWh depending on the configuration. High-efficiency models with servo motors and temperature control can reduce consumption by up to 40%.

That means in a typical 8-hour shift, total energy use can be as low as 4–12 kWh—less than many air compressors or industrial dryers.

⚙️ Key Features That Improve Energy Efficiency

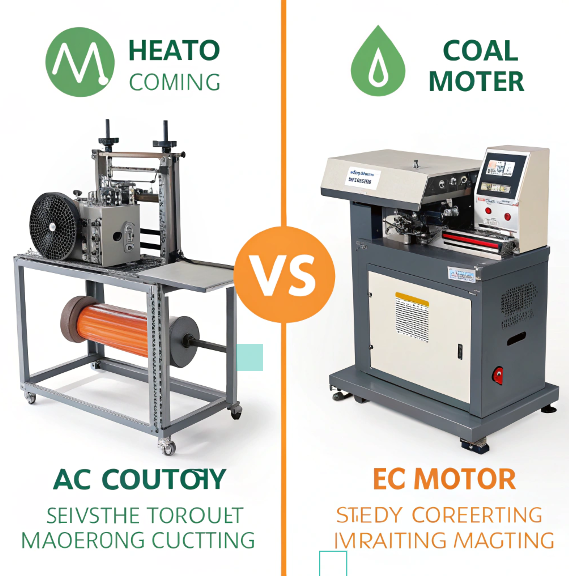

1. Servo Motor Systems

Servo motors only draw power when moving, unlike step motors or constant-speed motors that consume energy even when idle.

| Motor Type | Energy Efficiency | Suitable For |

|---|---|---|

| Step Motor | Medium | Budget machines |

| Servo Motor | High | Precision and energy-saving |

| AC Motor | Low | Legacy systems |

Our webbing tape cutting machine and automatic punching cutting machine use servo motors with digital feedback loops. These reduce both wasted movement and wasted power.

2. Smart Temperature Control

For hot and cold cutting machines, heat is a major energy drain. But modern controllers:

- Use real-time thermocouples to avoid overheating

- Adjust wattage output based on material thickness

- Enter eco-mode during idle phases

This setup allows machines to stay warm without constantly drawing full heat.

3. Low-Power Standby Modes

At Suzhou Haoxinhe, we install auto-sleep functions. If the operator walks away for 10 minutes, the machine reduces heat and motor functions to save energy.

This is ideal for smaller batches, prototyping, or when workers rotate between tasks.

📉 Energy Cost Estimate (Per Month)

Let’s look at a real-world scenario for Mark’s factory in Canada, running 2 shifts per day:

| Machine | Power (avg) | Daily Use | Monthly Energy Cost (USD) |

|---|---|---|---|

| Old AC-motor cutter | 2.5 kWh | 8 hrs | $72–85 |

| New servo + eco mode | 1.2 kWh | 8 hrs | $36–42 |

Even modest savings add up to over $500 per year—enough to justify upgrading to a new machine.

🏭 Energy-Conscious Design at Suzhou Haoxinhe

All our machines—from the PVC edge banding cutting machine to the protective foam cutting machine—are designed with energy efficiency in mind.

What we offer:

- Custom voltage settings (110V, 220V, 380V)

- Digital energy meters (optional)

- Eco-performance tuning for export clients

For bulk buyers and large production lines, we offer batch performance audits to help you track usage and optimize factory energy profiles.

⚠️ What to Watch Out For

Signs Your Machine Is Wasting Energy:

- Constant heating even when idle

- Loud, constant motor hum (no load)

- Warm housing or control panels

- Inconsistent cut quality (machine compensating via extra power)

If you see any of these signs, it may be time to upgrade to a newer model. Or contact our support team for a remote inspection.

Conclusion

Energy-efficient Velcro cutters are not only better for the environment—they also lower your factory’s monthly bills and improve machine lifespan.

Insights

One of the most overlooked expenses in Velcro production is energy waste—especially in older models running 10+ hours a day. I’ve visited factories where outdated cutters draw constant power even during breaks, just to keep the blade warm. Over a year, that adds up to thousands of dollars lost.

What savvy factory managers have started doing is treating energy use like a KPI. Clients in Europe now monitor kWh per batch just like material yield. That’s why we started offering optional digital wattmeters on our cutters—to make that data visible and actionable.

Another tip I give: match machine specs to your output volume. Don’t buy a 3kW hot cutter for a low-speed packaging line. That’s like using a jet engine to power a bicycle. Our team often helps clients downsize intelligently while still meeting throughput goals.

At Suzhou Haoxinhe, energy savings aren’t an afterthought—they’re baked into every servo motor, every eco-mode, and every thermal sensor. For serious manufacturers, energy efficiency is no longer optional—it’s your next margin.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. integrates energy-saving technology across all machines, including webbing ribbon cutting machines and hot/cold cutters. With servo motors, smart heating, and idle modes, our cutting equipment helps global B2B buyers maintain sustainability and save on operating costs—without sacrificing performance.