What are the differences between hot knife and cold blade Velcro cutters?

Are you struggling to find the right Velcro cutting machine for your production line? This guide clears up the confusion in under five minutes.

Hot knife and cold blade Velcro cutters differ mainly in cutting technique and edge quality. A hot knife uses heat to cut and seal synthetic Velcro, preventing fraying and offering a clean finish. In contrast, a cold blade slices mechanically like scissors, suitable for various materials but may leave frayed or raw edges. This key difference impacts application, durability, and finish quality.

Not all cutting machines are created equal. And choosing the wrong one can mess up your product finish, cause material waste, or delay your delivery time. Let me walk you through which type works better for your use.

Which cutting method is more suitable for your materials?

Sometimes your material tells you what machine to use—you just have to know how to listen. But what if you’re working with multiple materials like nylon Velcro, polyester tape, or laminated webbing? That’s when the decision gets tricky.

If your material frays easily or melts under heat, you need a hot knife cutter. If it is thick, layered, or sensitive to heat, then a cold blade is safer and cleaner.

Understand Your Material Composition

Choosing between a hot knife and cold blade Velcro cutter depends heavily on what your material is made of:

| Material Type | Hot Knife Cutter | Cold Blade Cutter |

|---|---|---|

| Nylon Velcro | ✅ Excellent | ❌ May fray |

| Polyester webbing | ✅ Seals edges | ❌ Frays |

| Cotton or canvas tape | ❌ Burns | ✅ Precise cut |

| Laminated/Composite | ❌ Melts unevenly | ✅ Clean cut |

| PVC edge banding | ✅ Controlled heat | ❌ Chipping |

| Protective foam tape | ❌ Deforms | ✅ Accurate trim |

I remember a client from the printing industry—Mark from Canada—who once ordered a batch of hot knife webbing cutters for his polyester Velcro straps. But when he added a paper-laminated foam edge to the product line, the same cutter started leaving burn marks. We quickly swapped to a cold blade design from our HAOXINHE automatic punching cutting machine range. Problem solved in two days.

Match the Cutter to Your Workflow

A hot knife cutter, like the ones we build at Suzhou Haoxinhe Electrical Equipment Co., Ltd., uses a heated blade to melt and seal the edge. It works great for synthetic webbing, ribbon, or hook-and-loop (Velcro) materials that fray easily. It’s common in:

- Textile production

- Shoemaking

- HVAC duct wrap cutting

- Industrial labeling systems

Cold blade cutters, on the other hand, use mechanical pressure to slice through the material. These are better when edge finish matters less than cut accuracy or when heat would damage layered material structures. For example:

- Protective foam tape

- Laminated paper roll

- Fabric with adhesives

- Lab filter materials

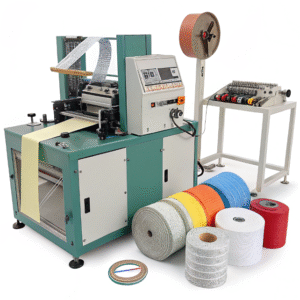

At HAOXINHE, we offer both types: hot and cold cutting machines, high-speed automatic Velcro cutters, and even rotary bevel cutters for special shapes.

Think Long-Term: Maintenance and Safety

Besides the material fit, think about machine longevity and safety.

- Hot knife cutters require periodic blade replacement and temperature calibration.

- Cold blade cutters usually last longer and are easier to maintain—but they demand sharp blades for a clean cut.

HAOXINHE’s cold blade computer tube cutters and wire cutting machines come with smart blade wear indicators to help your team avoid faulty cuts due to dull edges.

Conclusion

Hot knife cutters are best for sealing synthetic webbing. Cold blades are better for layered or heat-sensitive materials.

Insights

Suzhou Haoxinhe Electrical Equipment Co., Ltd. helps you match the right cutter to your Velcro, webbing, or protective foam material. Our factory offers both hot and cold blade machines with customizable features, ensuring your production is clean, efficient, and on-time. Whether you need a bubble wrap cutting machine or a rotary bevel cutting system, we engineer precision into every cut.

In my experience, the biggest misunderstanding among new manufacturers is assuming hot knife and cold blade cutters are interchangeable. They’re not. Hot knives are unbeatable for synthetic Velcro—especially in industrial settings—because they seal the edges while cutting, reducing fray and post-processing time. But that same heat can damage sensitive or composite materials. Cold blades, while slower and sometimes messier at the edge, offer much more control and material flexibility. The right choice isn’t just about sharpness—it’s about understanding how heat interacts with your fabric.

Insight: Choosing Between Hot Knife and Cold Blade Velcro Cutters – From a Manufacturer’s Perspective

After over two decades in the materials and textile processing industry, I’ve seen countless production lines stall or underperform simply because the wrong cutting tool was used for the job. When it comes to Velcro (hook-and-loop fasteners), the choice between a hot knife and a cold blade cutter isn’t just about preference—it’s about material compatibility, edge integrity, and operational efficiency.

Hot knife cutters work by melting through materials, which can seal the edges and prevent fraying. This is particularly useful when working with nylon or polyester-based Velcro, as the heat cauterizes the cut edges, reducing post-processing time and increasing durability. However, this method can cause material discoloration or warping if the temperature isn’t precisely controlled. Inconsistent power supply or a low-quality blade can also lead to residue buildup and charred edges—especially problematic in high-volume operations.

Cold blade cutters, in contrast, use a sharp metal blade to shear through the Velcro. This method is ideal for cotton or non-synthetic fasteners, where heat might damage the fibers. It also offers a cleaner, more precise cut with less chance of thermal deformation, making it suitable for high-precision applications like aerospace or medical-grade fasteners. The downside? Edges can fray over time, and frequent blade maintenance is required to maintain sharpness and accuracy.

From an operations perspective, I often recommend this decision matrix:

- Use hot knife cutters for synthetic materials where sealed edges are a priority.

- Use cold blades for natural or sensitive materials that cannot tolerate heat.

Ultimately, your choice should reflect your material type, production speed, and quality control standards. Investing in the wrong cutting method can lead to costly rework, increased waste, and customer complaints—issues no manufacturer can afford in today’s competitive landscape.