Velcro Dot Die Cutting Machine for Home Product Brands?

Cutting Velcro dots by hand slows down your brand’s growth — and your packaging quality suffers with every uneven piece.

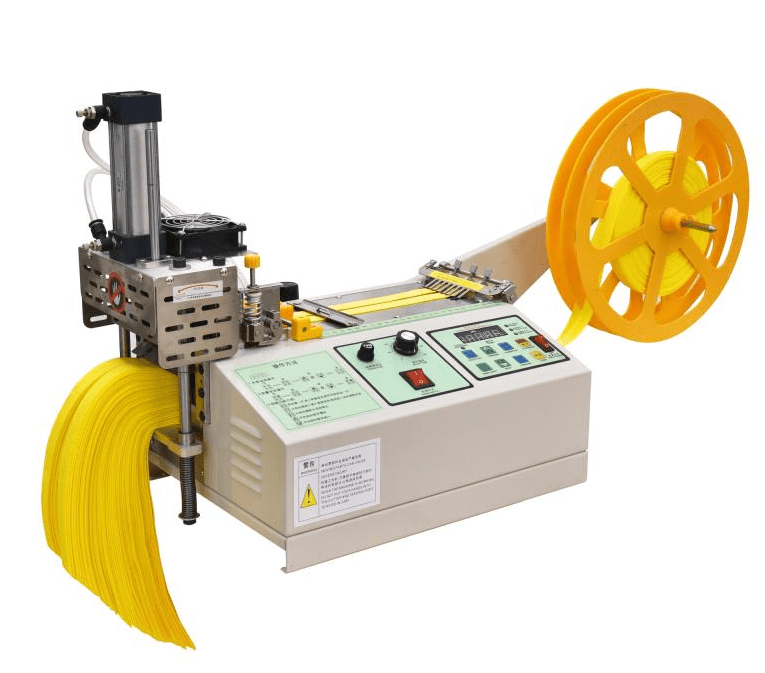

Our Velcro dot die cutting machine1 helps home product brands2 produce high volumes of clean, uniform Velcro dots for packaging, storage, and product bundling.

If your brand includes anything that snaps, seals, or organizes, this blog will show you how dot-cutting automation can elevate your production instantly.

Why do home product brands use Velcro dots?

Organizers, soft cases, kids’ toys, and reusable packaging all benefit from Velcro dots — but precision matters when they’re visible to customers.

Velcro dots offer a clean, reusable closure solution for modern home products, especially those focused on minimalism, reusability, or child safety.

Common Use Cases in the Home Sector

| Product Type | Velcro Dot Function |

|---|---|

| Drawer Organizers | Secure compartments |

| Storage Bins | Lid closures |

| Kids’ Educational Toys | Repositionable parts |

| Cable Management Kits | Bundle and release cords |

| Soft Home Goods | Snap-free sealing |

Home product brands often deal with many SKUs in various sizes. This makes uniform dot cutting critical for:

- Professional look

- Functional performance

- Scaled production

Hand-cutting fails in all three areas, especially when adhesive backing is involved.

What is a Velcro dot die cutting machine1://www.americanmicroinc.com/resources/how-die-cutting-save-time-money-manufacturing-process/)3 machine?

Most cutting machines slice straight lines. Dots? That requires precision and rotation.

A Velcro dot die cutting machine1://www.americanmicroinc.com/resources/how-die-cutting-save-time-money-manufacturing-process/)3 machine uses rotary dies to cut perfect circles from Velcro tape or sheets — automatically and continuously.

Core Features from Suzhou Haoxinhe Electrical Equipment Co., Ltd.

- Rotary Bevel Cutting System: For precise, burr-free circles

- Roll-to-Roll Feeding: Supports continuous high-volume output

- Pressure Adjustment: For various Velcro thicknesses

- Adhesive Support: Handles sticky-backed Velcro without residue buildup

- Auto Waste Separation: Clean removal of matrix material

We offer fully automatic rotary die cutters that support not just Velcro, but also other round-shape adhesive materials.

This makes it perfect for multi-material brands who work with felt pads, foam seals, or double-sided tape in packaging.

How does die-cutting Velcro dots improve efficiency?

When you’re doing 200-500 kits a day, every second counts. And manual cutting wastes time, material, and labor.

Die cutting increases productivity by more than 10x, while reducing per-dot costs and eliminating sizing errors completely.

Efficiency Breakdown

| Method | Output/hr | Accuracy | Labor Need | Consistency |

|---|---|---|---|---|

| Hand-Cutting | 200–300 dots | Low (±2mm) | 1–2 workers | Low |

| Manual Die Punch | 500–800 dots | Medium (±1mm) | 1 worker | Medium |

| Haoxinhe Rotary Machine | 10,000+ dots | High (±0.2mm) | 0.5 operator | High |

For example, one of our U.S.-based clients cut production time for their toy packaging by 80% after switching from hand-cutting to our dot machine. The upgrade paid for itself in under six months.

Can it handle different sizes and materials?

Product lines grow — and so do size and shape requirements. A good machine should adapt, not hold you back.

Yes — our dot die cutting machines support multiple dot diameters, adhesive types, and even custom shapes using interchangeable rotary dies.

Easy Size Switching

Our rotary machines are built for flexibility:

- Quick-Change Die Heads: Swap out die cylinders in minutes

- Software Adjustment: Match cut speed and pressure to new material

- Multi-Size Jobs: Split runs into multiple sizes with software batching

This is ideal for brands that offer:

- Small Velcro dots for hidden packaging closures

- Medium dots for toy parts and game kits

- Large dots for storage bins or heavy-duty home goods

Supported Materials

| Material Type | Suitability |

|---|---|

| Nylon Velcro | ✅ Excellent |

| Polyester Velcro | ✅ Excellent |

| Adhesive-Backed | ✅ Supported with cold-cutting |

| Foam-Based Dots | ✅ Compatible |

| Hook & Loop Tape | ✅ Fully supported |

This means brands can centralize dot production across multiple product lines and materials, simplifying inventory and reducing vendor dependency.

Is it worth the investment for a growing home brand?

When you’re scaling up, every tool must contribute to revenue. A cutting machine needs to boost output, reduce error, and lower cost.

For brands producing over 500 units/month, a Velcro dot die cutting machine1 can deliver ROI within 4–7 months — with ongoing savings year-round.

Cost & Output Comparison

| Metric | Before Machine | After Machine |

|---|---|---|

| Dots/day | 800–1000 (manual) | 10,000+ |

| Operators | 2 workers | 1 part-time |

| Dot Consistency | ±2mm | ±0.2mm |

| Dot Unit Cost | $0.025 | $0.007 |

| Monthly Waste | High | Low |

And because our machines from Suzhou Haoxinhe Electrical Equipment Co., Ltd. are built for industrial longevity, you avoid frequent repairs or downtime.

With customizable models for small, mid-size, and full-scale manufacturers, there’s a machine that fits both your space and your growth plans.

Conclusion

For home product brands that rely on Velcro dots, our rotary die cutting machine transforms a slow, error-prone task into a fast, automated process with scalable output.

Insights

Home product brands that need clean, consistent Velcro dot cuts for organizers, soft goods, toys, and packaging will benefit from automation. Suzhou Haoxinhe’s rotary bevel cutting machine offers 10,000+ dots/hour output, ±0.2mm precision, and support for various materials. With quick ROI and consistent results, it’s the perfect upgrade for growing DIY and home brands looking to scale packaging quality and speed.

Explore how a Velcro dot die cutting machine can enhance your production efficiency and quality, making it a worthwhile investment for your brand. ↩ ↩ ↩ ↩

Discover the common challenges faced by home product brands and how automation can help overcome them, ensuring better quality and efficiency. ↩

Learn about the advantages of die cutting in manufacturing, including increased productivity and reduced costs, essential for scaling your business. ↩ ↩