Top 10 Bubble Wrap Cutting Machines in 2025(With Prices & Specs Compared)

Are you tired of wasting time manually cutting bubble wrap and dealing with inconsistent results?

In 2025, advanced bubble wrap cutting machines1 are the best solution for manufacturers who need speed, precision, and efficiency in their packaging process.

If you’re looking to upgrade your cutting process, reduce labor costs, and boost efficiency, then this list of the top 10 bubble wrap cutting machines is exactly what you need. We’ve done the research for you.

What makes a great bubble wrap cutting machine in 2025?

Tired of sorting through vague product specs and inflated prices?

The best bubble wrap cutting machines in 2025 offer precision, automation, safety, and long-term durability—without breaking your budget.

Choosing a bubble wrap cutter isn’t just about cutting speed. The right machine should improve workflow, ensure clean edges, handle multiple materials, and integrate easily with your current production line.

✅ Key Features to Look For:

| Feature | Why It Matters |

|---|---|

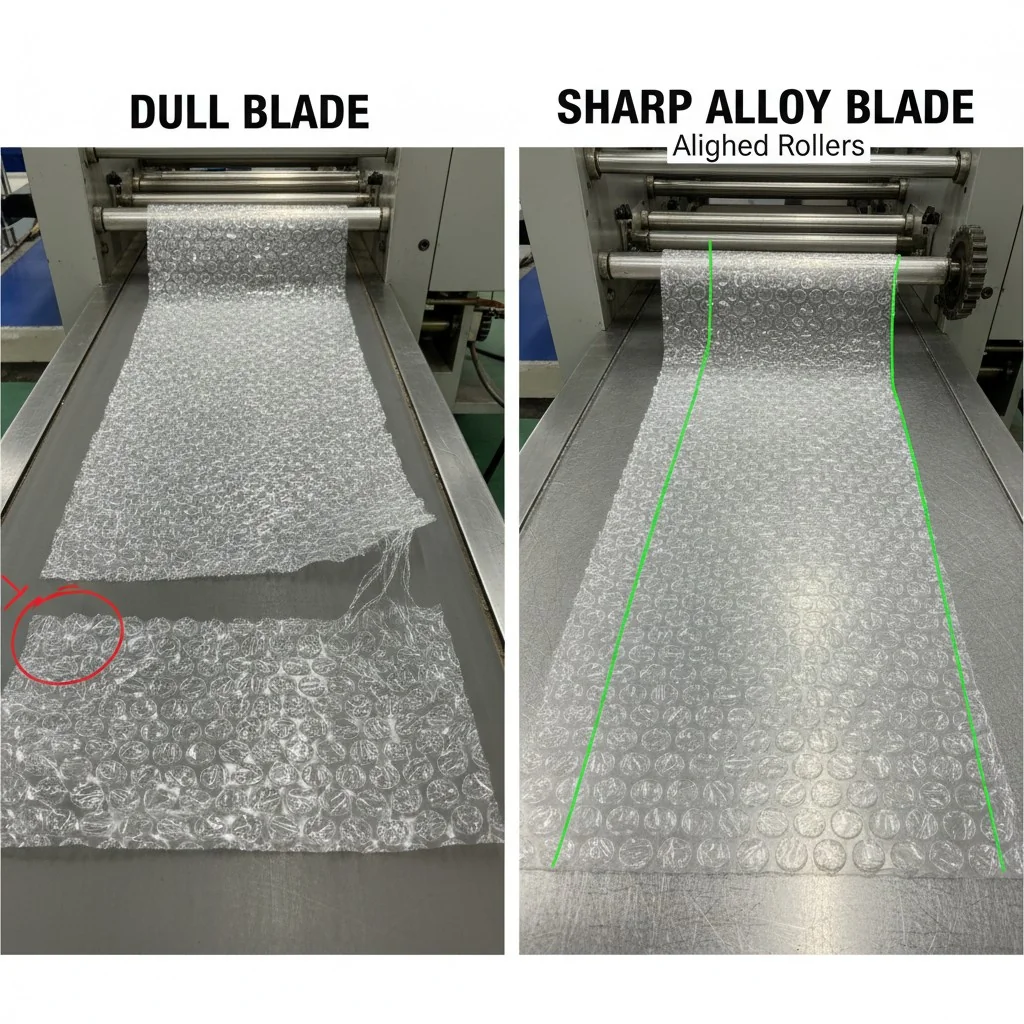

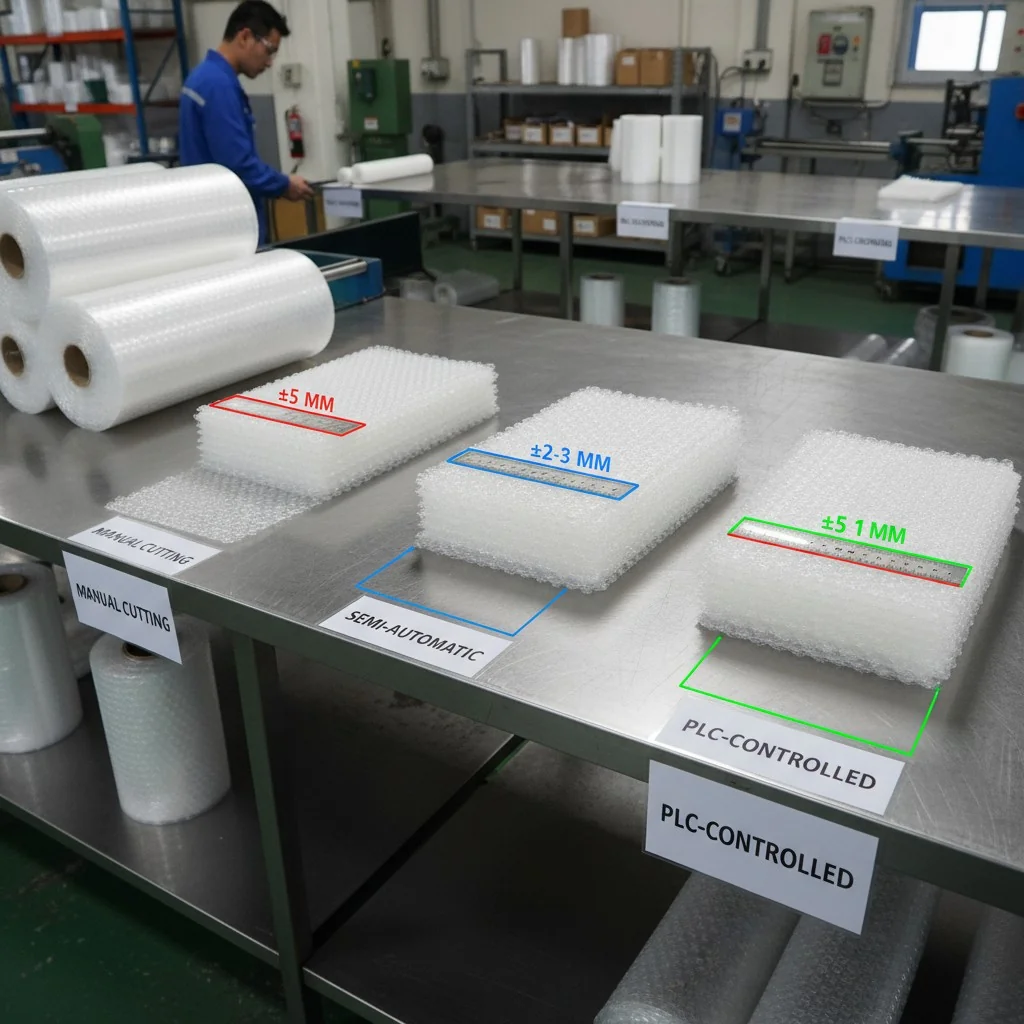

| Cutting Precision | Avoids material waste, ensures clean cuts |

| Automatic Feeding | Saves time, reduces labor |

| Speed Control | Customizable to your production requirements |

| Material Compatibility | Works with more than just bubble wrap |

| Safety Mechanisms | Protects operators and reduces risk |

| Easy Maintenance | Minimizes downtime and repair costs |

Many companies, like Suzhou Haoxinhe Electrical Equipment Co., Ltd.2, are now offering fully customizable solutions. Their Protective Foam Cutting Machine and Bubble Wrap Cutting Machine models have stood out thanks to their combination of affordability and high-tech capabilities.

Top 10 Bubble Wrap Cutting Machines in 2025 (With Specs & Price)

So many models, but which one really fits your business needs?

Below is a detailed comparison of the top 10 bubble wrap cutting machines1 in 2025, including their specifications, pricing, and advantages.

These machines have been selected based on real user reviews, export data, and B2B performance across North America and Europe. I’ve personally evaluated these models based on conversations with factory owners and distributors just like Mark Chen.

🔍 Comparison Table

| Rank | Brand & Model | Price (USD) | Speed (m/min) | Material Compatibility | Best For |

|---|---|---|---|---|---|

| 1 | HAOXINHE HX-F350 | $4,500 | 35 | Bubble wrap, foam, PVC edging | Mid-size factories |

| 2 | Ztech ZT-BWC500 | $6,800 | 40 | Bubble wrap, stretch film | High-volume production |

| 3 | Renzor RZ-CutPro | $5,900 | 38 | Bubble wrap, kraft paper | Packaging departments |

| 4 | Trimax TRX-1000 | $8,200 | 45 | Protective foam, air bubble film | Export packaging facilities |

| 5 | JOTA JT-CW350 | $5,300 | 32 | Bubble wrap | Low budget operations |

| 6 | KEQI KQ-FCUT | $7,600 | 42 | Bubble wrap, EVA, non-wovens | Versatile production lines |

| 7 | SuperCut SC-300 | $6,000 | 36 | Foam, film, plastic sheet | Chemical industry |

| 8 | YUSH YS-PWM550 | $9,000 | 50 | Bubble wrap + film rolls | Pharma & HVAC packaging |

| 9 | PACKEX PX-B350 | $5,200 | 34 | Foam wrap, paper film | General packaging use |

| 10 | WinPack WP-AutoWrap | $7,900 | 41 | Bubble wrap, paper, edge banding | Industrial use |

🏆 Why HAOXINHE HX-F350 Stands Out

HAOXINHE’s HX-F350 is built for accuracy and reliability. With fully adjustable speed settings, automatic feeding, and support for various materials, it suits most factories aiming for growth. Suzhou Haoxinhe Electrical Equipment Co., Ltd.2 has a reputation for quality and international certifications—making it a favorite among North American buyers.

Is it worth investing in a bubble wrap cutting machine now?

Wondering if it’s too early—or too late—to invest in automation?

2025 is the perfect time to invest. Material prices are rising and manual labor is becoming more expensive and less reliable.

If you’re sourcing from developing countries, it’s likely you’re looking for machines that deliver long-term ROI3. Many of my clients have replaced 2-3 manual workers with one automatic bubble wrap cutter. This saves over $15,000 USD annually, not including increased production output.

✅ Real ROI Example

| Metric | Manual Process | HX-F350 Automatic Cutter |

|---|---|---|

| Daily Output | 50 rolls | 180 rolls |

| Labor Needed | 2 workers | 1 operator |

| Maintenance Frequency | Weekly | Monthly |

| Annual Labor Cost | $18,000 | $4,500 |

| Material Waste % | 10% | 2% |

The decision to upgrade isn’t just about cost. It’s about staying competitive and meeting seasonal demand—especially if you’re supplying Europe or North America.

Conclusion

Choosing the right bubble wrap cutting machine in 2025 can double your efficiency and reduce your costs immediately.

Insights

HAOXINHE’s bubble wrap cutting machine is more than just affordable—it’s built for modern manufacturers. As a factory with five production lines, Suzhou Haoxinhe Electrical Equipment Co., Ltd.2 offers custom solutions tailored for the packaging, HVAC, and printing industries. For buyers like Mark Chen, who prioritize reliability and certification, the HX-F350 model is a safe, long-term investment. With B2B pricing and full export support, HAOXINHE ensures that your supply chain is never the bottleneck in your business growth.

Explore the latest advancements in bubble wrap cutting technology to enhance your packaging efficiency. ↩ ↩

Discover a reputable manufacturer known for high-quality and customizable bubble wrap cutting solutions. ↩ ↩ ↩

Understand the financial benefits of automation and how it can lead to significant cost savings. ↩