The Future of Adhesive Velcro Cutting in DIY Packaging?

DIY brands are booming — but messy, imprecise Velcro cuts are hurting their packaging quality and efficiency.

With precision machines like our webbing ribbon cutting machine, even small DIY packaging businesses can achieve professional-grade adhesive Velcro cuts at scale.

This blog is a deep dive into how automation is transforming Velcro cutting in the DIY packaging space — and why now is the time to upgrade.

Why is adhesive Velcro so popular in DIY packaging?

Straps, flaps, folders — Velcro is everywhere in handmade packaging. But hand-cut Velcro leads to waste, uneven cuts, and slow output.

Adhesive Velcro offers a clean, reusable, and customizable fastening option that appeals to both eco-conscious and design-minded DIY brands.

A Fastener for Modern Needs

Velcro ticks all the boxes for small brands looking to elevate their packaging:

- Reusable: Adds value and longevity to the product.

- Customizable: Can be cut to any size or shape.

- Clean Look: No hooks, holes, or staples needed.

- Safe: Especially important for children’s products and crafts.

However, cutting it manually — with scissors or box cutters — slows down even the most productive workshop.

Where DIY Brands Use Velcro

| Product Type | Velcro Usage |

|---|---|

| Handmade Bags | Closure flaps |

| Craft Kits | Modular compartments |

| Subscription Boxes | Re-sealable pouches |

| Jewelry Packaging | Display & attachment |

| Toy Packaging | Child-safe seals |

DIY packaging is no longer just functional — it’s an extension of the brand. And Velcro, when cleanly cut and well-applied, enhances the experience.

What are the common challenges of cutting Velcro manually?

Precision is difficult. Volume is limited. Waste is high.

Manual Velcro cutting in DIY settings often leads to jagged edges, misaligned pieces, and inconsistent dimensions — all of which affect the final look and usability.

Common Problems DIY Sellers Face

1. Inconsistent Sizes

When cutting with scissors, even slight hand tremors cause irregular sizes. This inconsistency becomes obvious when packaging multiple items in the same box.

2. Fraying & Adhesive Tearing

Many DIY brands use adhesive-backed Velcro. But without a clean slicing tool, the glue layer separates, or the edge frays.

3. Time-Consuming

Cutting 100 pieces of 25mm Velcro can take over an hour manually. That’s time that could be used for assembly, labeling, or marketing.

4. Material Waste

Crooked cuts lead to unusable leftovers. When you’re operating on a tight budget, every centimeter counts.

These pain points have pushed some makers to limit or eliminate Velcro use — but there’s a better option.

How can machines help DIY brands cut Velcro more efficiently?

Big factories aren’t the only ones who benefit from cutting automation anymore — even small businesses can use affordable machines.

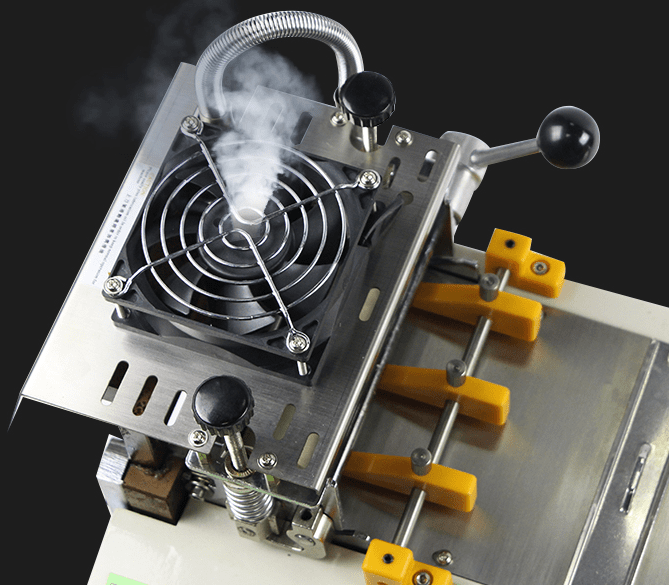

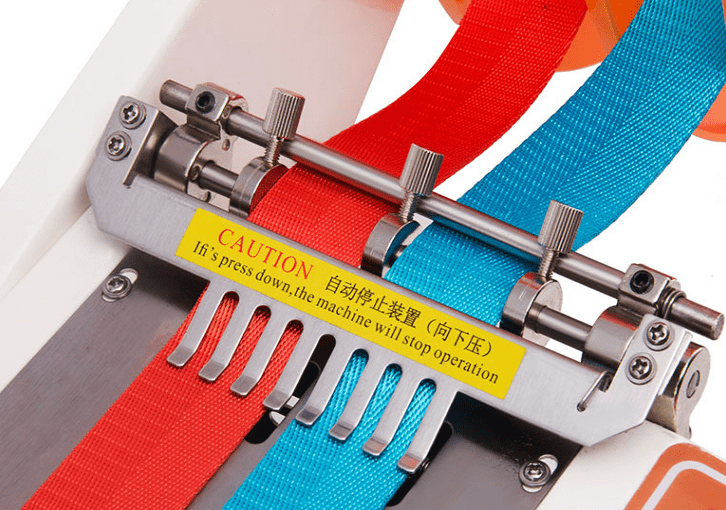

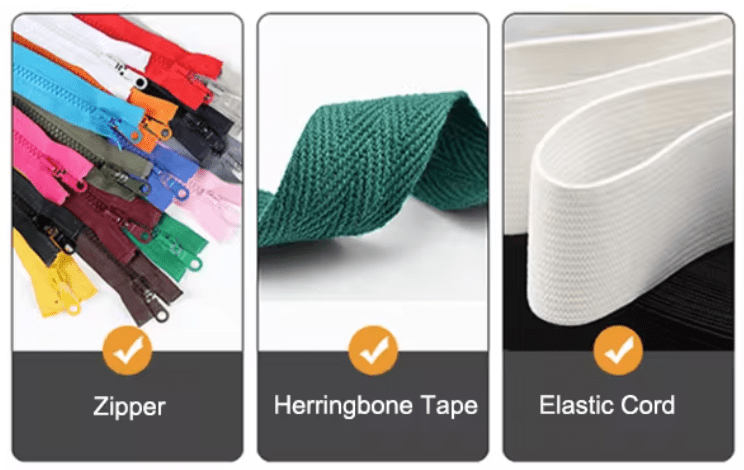

Our small-scale hot and cold cutting machine enables DIY brands to cut adhesive Velcro strips and dots with precision, speed, and minimal waste.

Key Features for DIY Use

Suzhou Haoxinhe Electrical Equipment Co., Ltd. builds compact models tailored for limited spaces and lower outputs:

- Auto-Length Programming: Enter length, and the machine cuts exact sizes.

- Heat Cutting Mode: Prevents fraying on soft Velcro tapes.

- Cold Mode Option: Perfect for adhesive Velcro with pressure-sensitive backing.

- Tabletop Size: Fits in small studios and workshops.

- Low Power Consumption: Easy to run on standard outlets.

What It Means for You

| Metric | Manual Cutting | Haoxinhe Compact Machine |

|---|---|---|

| Output/hour | 80–100 pcs | 1000–2000 pcs |

| Cut Accuracy | ±3mm | ±0.2mm |

| Fraying | High | Zero (heat mode) |

| Setup Space | Minimal | Small (tabletop) |

| Operation | Manual labor | Button-click automation |

For just one-time orders or custom packaging kits, this level of control can make all the difference in professionalism.

Will automated Velcro cutting affect the "handmade" appeal?

For many creators, “handmade” is part of the brand. But that doesn’t mean every piece has to be hand-cut.

Smart automation keeps the artisan touch intact — while improving consistency, reducing errors, and elevating perceived value.

Balancing Craft and Efficiency

Just like screen printing or 3D laser engraving, machine-cutting Velcro is a tool, not a shortcut. You still:

- Choose the material

- Decide where to apply it

- Assemble the product by hand

In fact, clean Velcro application often makes your packaging look more professional, which builds customer trust.

Client Story: Small Brand, Big Upgrade

One of our clients — a craft jewelry seller in France — switched to our compact webbing ribbon cutting machine. She used to cut Velcro straps by hand for her gift boxes. After switching:

- Her daily output tripled

- Packaging looked cleaner and more uniform

- She received more 5-star reviews for “thoughtful presentation”

This is why many micro brands are now investing in simple automation.

Conclusion

Automated Velcro cutting empowers DIY packaging brands to produce cleaner, faster, and more professional results without sacrificing creativity.

Insights

DIY brands are moving beyond scissors and into automation. With machines like our tabletop hot and cold cutting machine, small businesses can cut adhesive Velcro strips and dots faster, cleaner, and more consistently. This helps them scale without losing their handmade aesthetic. Whether you’re packaging jewelry, crafts, or kids’ products, automation brings new power to your brand — and Suzhou Haoxinhe is here to help you make the leap.