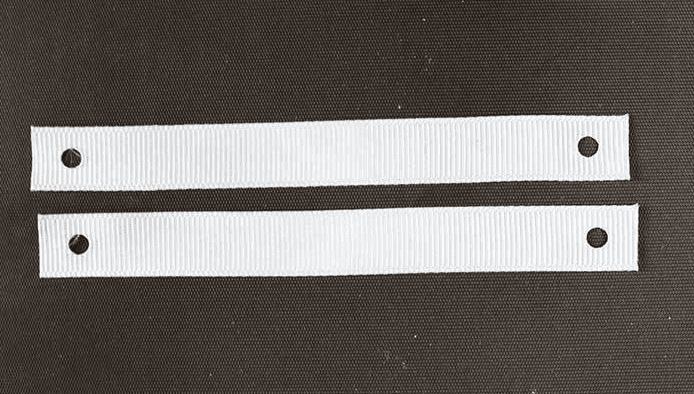

Making Holes in Nylon Webbing Without Ruining It?

I remember the first time I made holes in nylon webbing with the wrong tool—it melted, frayed, and cost me an entire batch of straps.

To make clean, durable holes in nylon webbing, use a heated punch tool1 that seals the fibers as it cuts, supported by firm clamping and precision alignment.

This article will walk you through my complete process, the tools I use in my factory, and how to avoid the common mistakes most people make.

Why Is Nylon Webbing So Hard to Punch?

Nylon webbing is strong but thermoplastic. That means it melts before it tears. If you use scissors or a cold punch, it either frays or warps.

Nylon’s melting point requires you to use controlled heat during hole-making to avoid fiber breakdown or weak edges.

What Goes Wrong with Cold Punching?

| Method Used | Result | Problem |

|---|---|---|

| Scissors | Jagged, frayed holes | No seal on edges |

| Standard punch | Torn webbing or misaligned hole | Doesn’t melt or seal nylon fibers |

| Lighter sealing | Inconsistent finish | Risk of overheating or deforming |

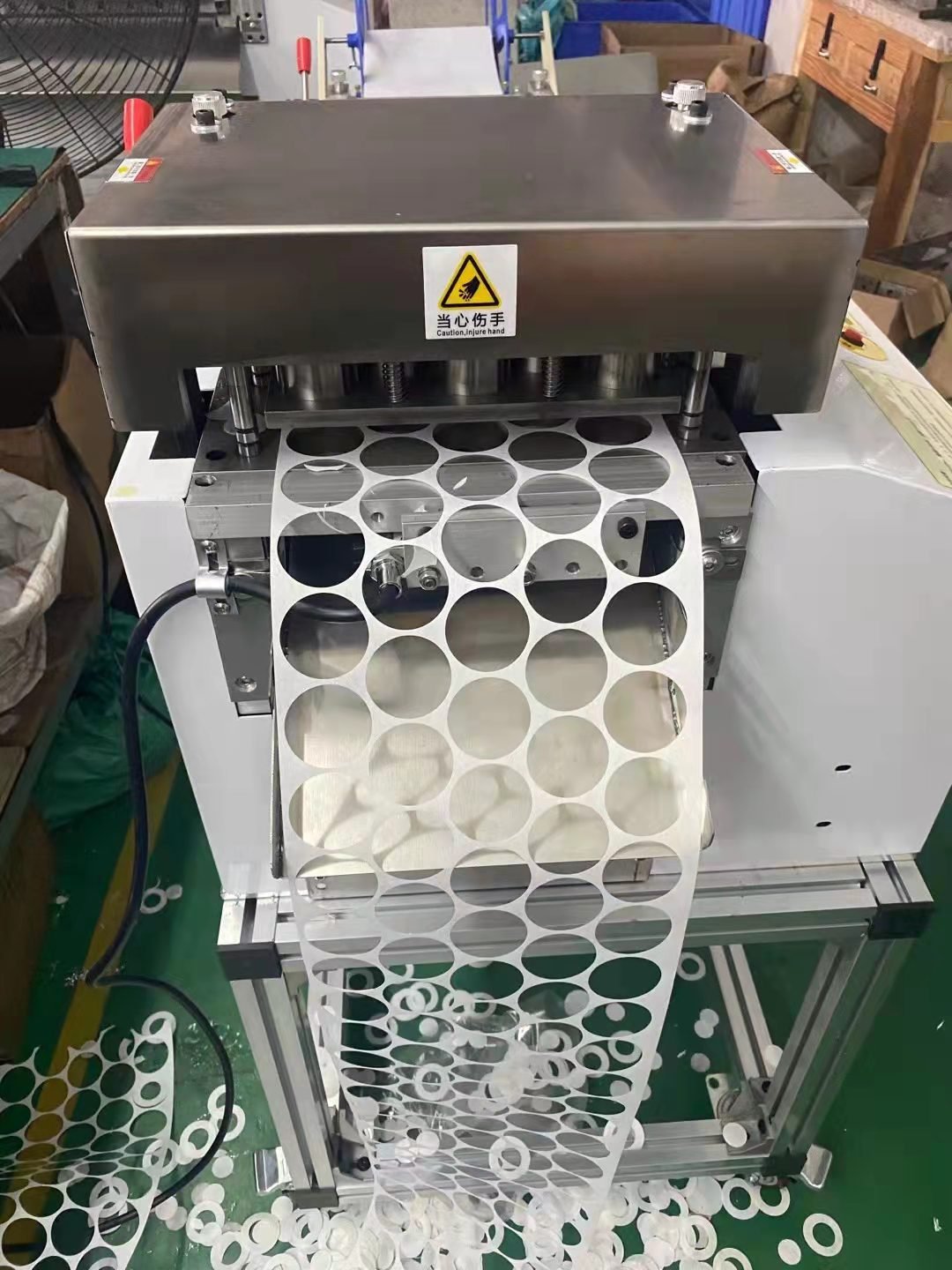

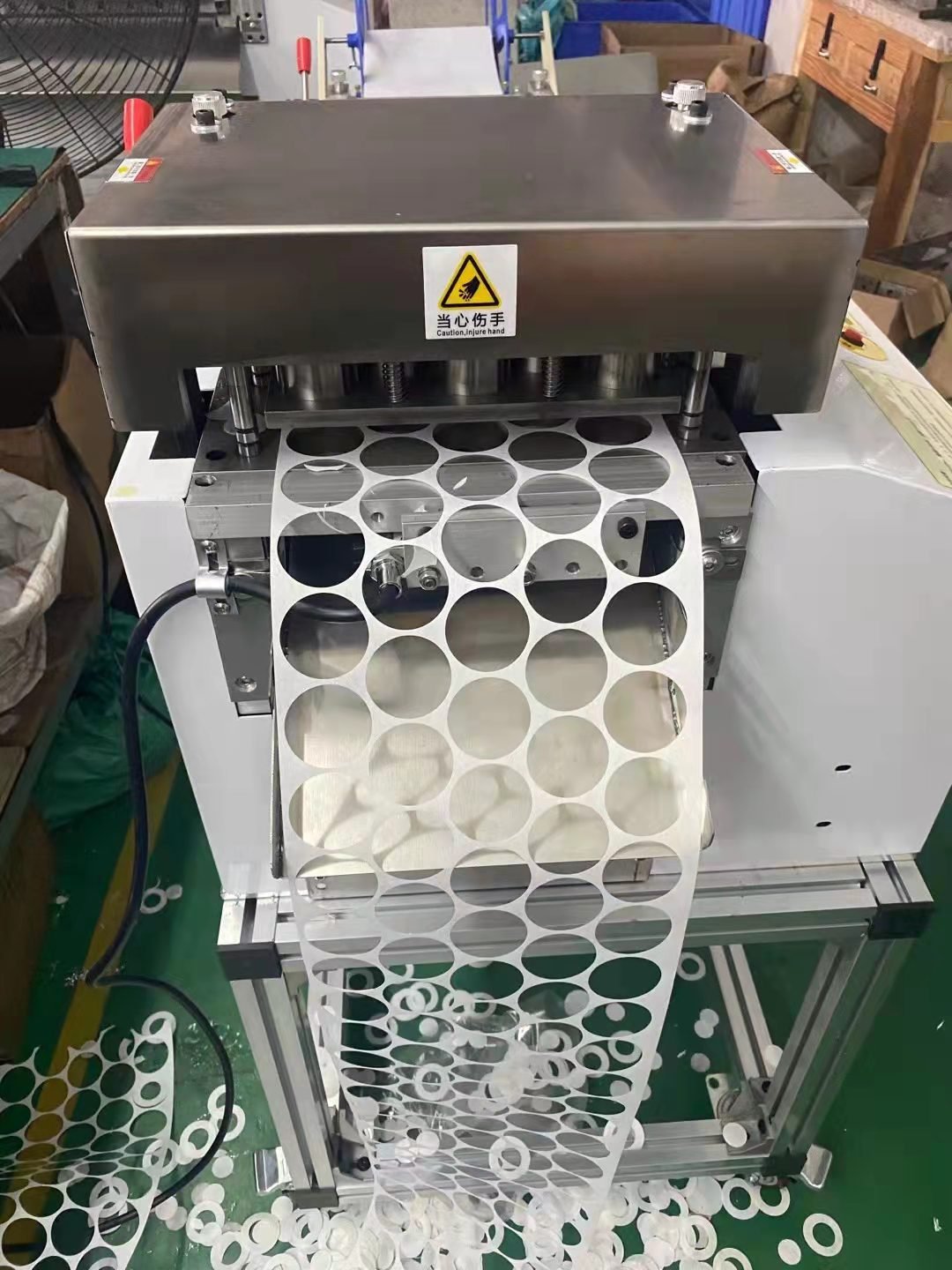

I used to manually punch holes and seal with a lighter. That worked—sometimes. But once I switched to automatic punching cutting machine2s from Suzhou Haoxinhe Electrical Equipment Co., Ltd., everything changed. Clean, sealed holes every time.

What Tools Are Best for Making Holes in Nylon Webbing?

You don’t need dozens of tools—you just need the right one. I’ve found that a hot punch tool, when mounted on a stable frame or CNC-controlled press, delivers the best results.

The most effective tools are heated punches or die cutters specifically designed for synthetic materials like nylon.

Recommended Tools

| Tool | Purpose |

|---|---|

| Heated Hole Punch | Melts and seals hole edges |

| Webbing Ribbon Cutting Machine | Prepares webbing to length and seals ends |

| Round Shape Cutting Machine | Cuts sealed circular holes at set intervals |

| Automatic Punching Cutting Machine | Handles multi-hole patterns with speed |

If you’re in the manufacturing or outdoor gear industry, I recommend integrating a rotary bevel cutting machine. It handles angled cuts and hole punching in one go.

Step-by-Step: How I Punch Clean Holes in Nylon Webbing

Here’s the exact process we follow in my production line, which produces straps for industrial clients across Europe and North America.

Use a hot punch with controlled heat, accurate alignment, and a firm cutting base to make smooth, durable holes in nylon webbing.

My Standard Workflow

Pre-cut Webbing

Use a webbing ribbon cutting machine3 to cut each piece to the desired length.Mark Punch Points

For manual jobs, use a heat-safe marker or laser guide.Preheat the Punch Tool

Set temperature around 260°C to 280°C, depending on webbing thickness.Secure the Webbing

Use clamps or jigs to prevent movement.Punch Steadily

Press the heated punch slowly to melt through and seal fibers.Inspect the Finish

Ensure no fraying or deformation.Repeat or Load into Auto Machine

For large volumes, switch to automatic CNC punching with saved patterns.

Tip: For multi-hole webbing, use our automatic punching cutting machine2 with custom mold heads for perfect spacing and speed.

How to Avoid Common Mistakes When Punching Nylon Webbing?

Even experienced buyers like Mark from Canada run into problems when they skip key steps or trust the wrong supplier.

Avoid fraying, melting, or hole misalignment by using the right punch tool, sealing as you cut, and testing samples before production.

Frequent Mistakes

| Mistake | Why It Happens | How to Fix |

|---|---|---|

| Using Cold Tools | Cheap or non-industrial punch sets | Use heated punch tool1s |

| Skipping Seal Test | Assumes punch is enough | Always inspect cut edges |

| Misalignment | Manual operation without guide | Use jigs or CNC punch heads |

| No Spare Dies | Low-quality supplier | Choose a factory with after-sale parts |

When my buyers choose Suzhou Haoxinhe Electrical Equipment Co., Ltd., they get more than a machine—they get tech support, custom die designs, and stable delivery even during peak seasons.

Conclusion

Making holes in nylon webbing the right way saves time, improves product quality, and prevents returns—invest in heated punches and precision tooling to get it right.

Insights

To make holes in nylon webbing without damage, use a heated punch tool1 with firm alignment and fiber-sealing capability. Suzhou Haoxinhe’s round shape cutting machines and automatic punching equipment ensure professional results every time.

Explore this link to understand the technology behind heated punch tools and how they ensure clean, durable holes in nylon webbing. ↩ ↩ ↩

Discover the advantages of automatic punching machines, including efficiency and precision, which can enhance your production process. ↩ ↩

Learn how webbing ribbon cutting machines streamline the cutting process, ensuring consistent lengths and sealed edges for high-quality products. ↩