Looking for a Heavy Duty 5mm Hole Punch for Plastic Cards?

When I needed to punch through thick plastic cards, most tools cracked the edges or left rough, uneven holes. That’s when I learned—not all punches are built the same.

The best heavy duty 5mm hole punch1 for plastic cards must offer clean cuts, no cracking, adjustable pressure, and hardened steel dies for repetitive use.

In this post, I’ll share what to look for, what machines we use in our facility, and how a properly chosen punch tool can improve both quality and efficiency.

Why Does Plastic Card Punching Require a Special Tool?

Plastic cards are rigid but brittle. A low-quality punch either breaks the card or leaves rough, jagged holes that don’t meet finish standards.

Plastic cards require a precision-grade punch with reinforced die sets, a stable base, and even pressure distribution to avoid chipping or deformation.

Common Issues with Standard Punches

| Problem | Cause | Result |

|---|---|---|

| Cracked Corners | Uneven pressure or dull punch head | Ruins the entire card |

| Oval or Misshaped Hole | Misaligned punch and poor base | Inconsistent quality |

| Burrs Around Hole | Weak or blunt punching die | Unprofessional finish |

That’s why I switched to industrial-grade punching equipment2 from Suzhou Haoxinhe3 Electrical Equipment Co., Ltd.—built for precision jobs like plastic ID card finishing.

What Features Define a Good 5mm Hole Punch for Plastic Cards?

Not every punch tool labeled “heavy-duty” actually performs that way. I’ve bought units that failed after 500 cards. The right punch must handle continuous work, clean holes, and tight tolerances.

Key features of a good 5mm hole punch include steel die-heads, ergonomic or pneumatic operation, and replaceable parts for long-term use.

Feature Checklist

| Feature | Why It’s Important |

|---|---|

| 5mm Precision Die | Ensures consistent hole size |

| Hardened Steel Blade | Maintains sharpness over high volumes |

| Anti-Slip Base | Stabilizes during punching |

| Pneumatic/Lever Assist | Reduces manual fatigue |

| Replaceable Dies | Easy maintenance, less downtime |

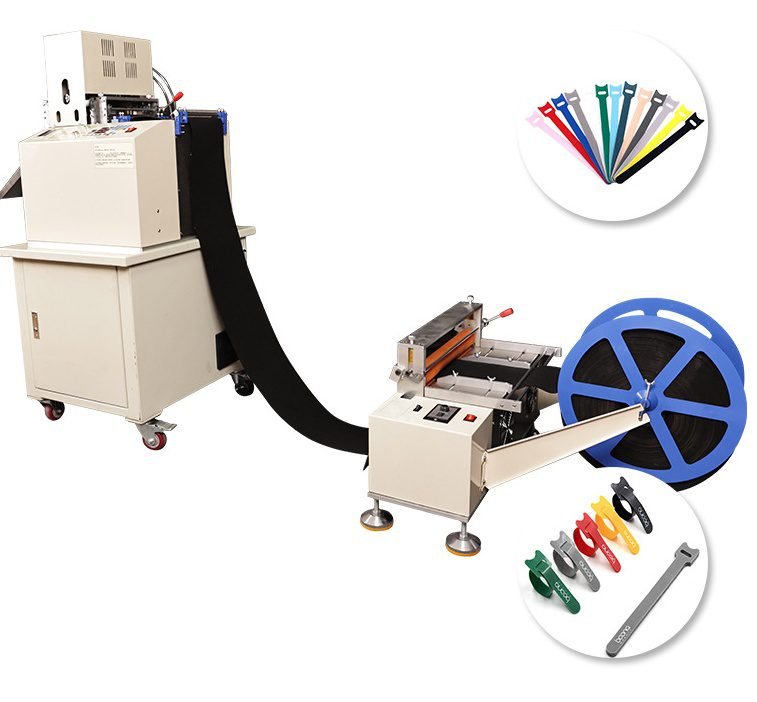

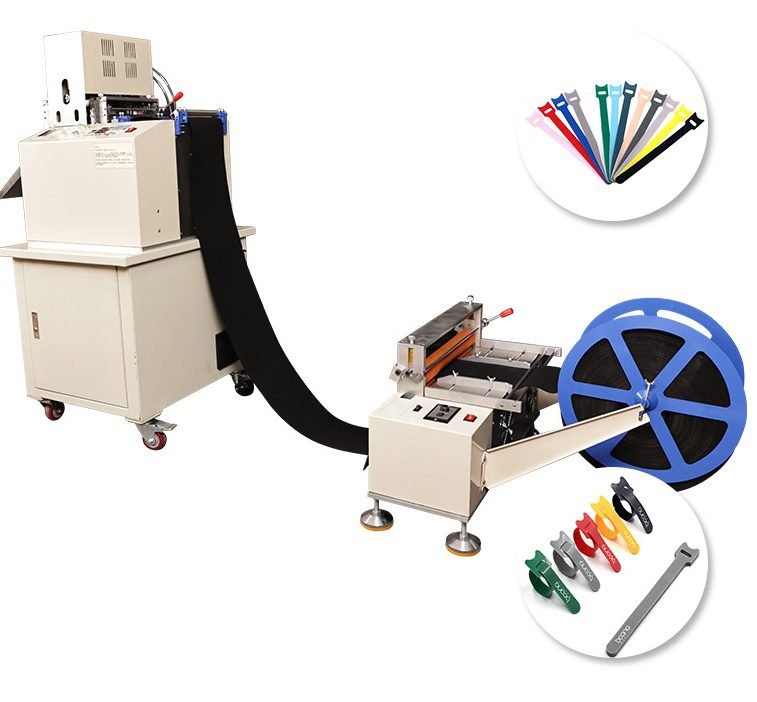

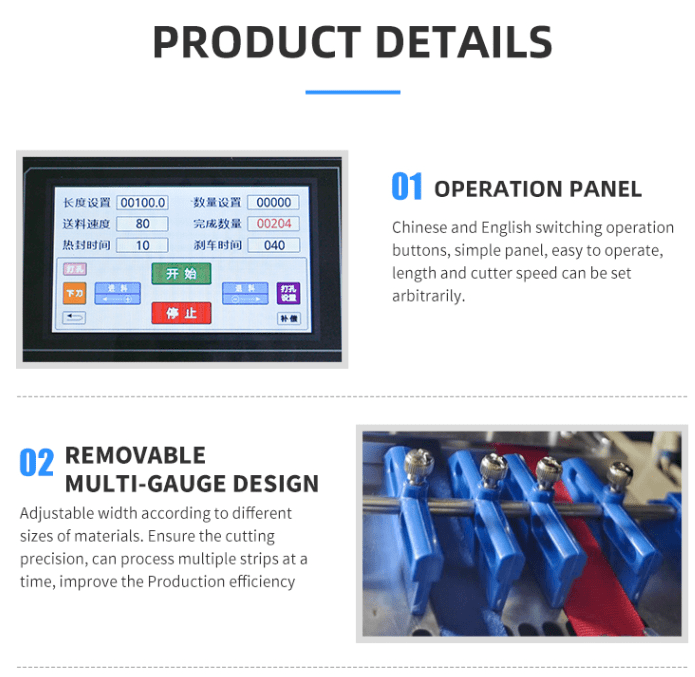

For plastic cards, I suggest a manual lever press for small-scale, or automatic punching cutting machine for batch jobs. Our Suzhou Haoxinhe3 machines handle up to 2,000 plastic cards/hour.

What Machines Are Best for Punching 5mm Holes in Plastic Cards?

Whether you’re punching loyalty cards, ID badges, or PVC tags, the tool must match your volume and precision needs.

The best options are industrial hot punch machines or reinforced mechanical punches that support a clean 5mm cut and eliminate cracking or misalignment.

Recommended Equipment from Suzhou Haoxinhe3

| Machine Type | Best For | Features |

|---|---|---|

| Automatic Punching Cutting Machine | High-volume card production | CNC positioning, customizable die heads |

| Round Shape Cutting Machine | Perfect 5mm hole applications | Sealed, clean holes, anti-jam system |

| Custom Manual Punch Tool | Prototyping and small batches | Hardened steel 5mm die, ergonomic handle |

These machines have been exported to clients in Canada, Italy, and Germany, especially those rebranding in bulk for retail card products.

If your material also includes laminated layers or RFID tags, you may want to ask for dual-pressure control during the punch to avoid internal damage.

How to Maintain Your Hole Punch for Long-Term Use?

Even the best punch tools wear out over time—especially when punching tough plastics. But proper care makes all the difference.

Clean the die regularly, lubricate moving parts, and replace worn blades before they dull—this preserves cut quality and protects your materials.

Simple Maintenance Tips

- Daily Cleaning: Use compressed air to remove debris from the die head.

- Lubrication: Apply oil to moving joints every 3–5 days of use.

- Blade Check: Inspect weekly for dullness or deformation.

- Alignment Check: Realign punch if holes start drifting off-center.

- Storage: Keep dry and covered when not in use.

At Suzhou Haoxinhe3, we offer full post-sale service, including spare dies and technical guidance—something many low-cost punch suppliers don’t provide.

Conclusion

For thick or laminated plastic cards, a reliable 5mm heavy duty punch is essential—and industrial-grade China-made machines provide the best performance-to-cost ratio.

Insights

Heavy-duty 5mm hole punches for plastic cards must deliver clean, crack-free results. Suzhou Haoxinhe3’s industrial punching machines combine CNC precision, hardened steel dies, and fast cycle times—ideal for ID cards, tags, or laminated badge production.

Explore this link to discover top-rated heavy duty hole punches that ensure clean cuts and durability for your plastic card projects. ↩

Learn about industrial-grade punching equipment that offers precision and efficiency for high-volume plastic card production. ↩

Check out Suzhou Haoxinhe’s offerings for reliable and efficient hole punching solutions tailored for plastic cards. ↩ ↩ ↩ ↩ ↩