Label Production Using Adhesive Velcro Punching Machines?

Traditional label cutters can’t handle Velcro — especially when it comes with adhesive backing and requires punch precision.

Our adhesive Velcro punching machine creates consistent, professional-quality labels for packaging, uniforms, electronics, and more — even in high volumes.

Let’s explore how this machine turns Velcro into reliable label components that boost both functionality and product value.

Why use adhesive Velcro for label production?

Not all labels need to be stuck on once and forgotten — some need to move, reposition, or be reused.

Adhesive Velcro labels are a flexible, reusable solution that stick securely, peel cleanly, and allow repositioning — ideal for dynamic labeling needs.

Common Use Cases

| Industry | Velcro Label Application |

|---|---|

| Uniforms & Gear | Name tags, rank badges |

| Electronics | Cable tags, port labeling |

| Retail | Shelf tags, price changes |

| Event & Rental | Equipment ID & sorting |

| Healthcare | Patient labels, supply bins |

Manufacturers and end-users benefit from:

- Fast application

- Clean removal

- Durability

- Reusability across surfaces

But for this to work, the label shape must be exact — and cleanly punched. That’s where automation matters.

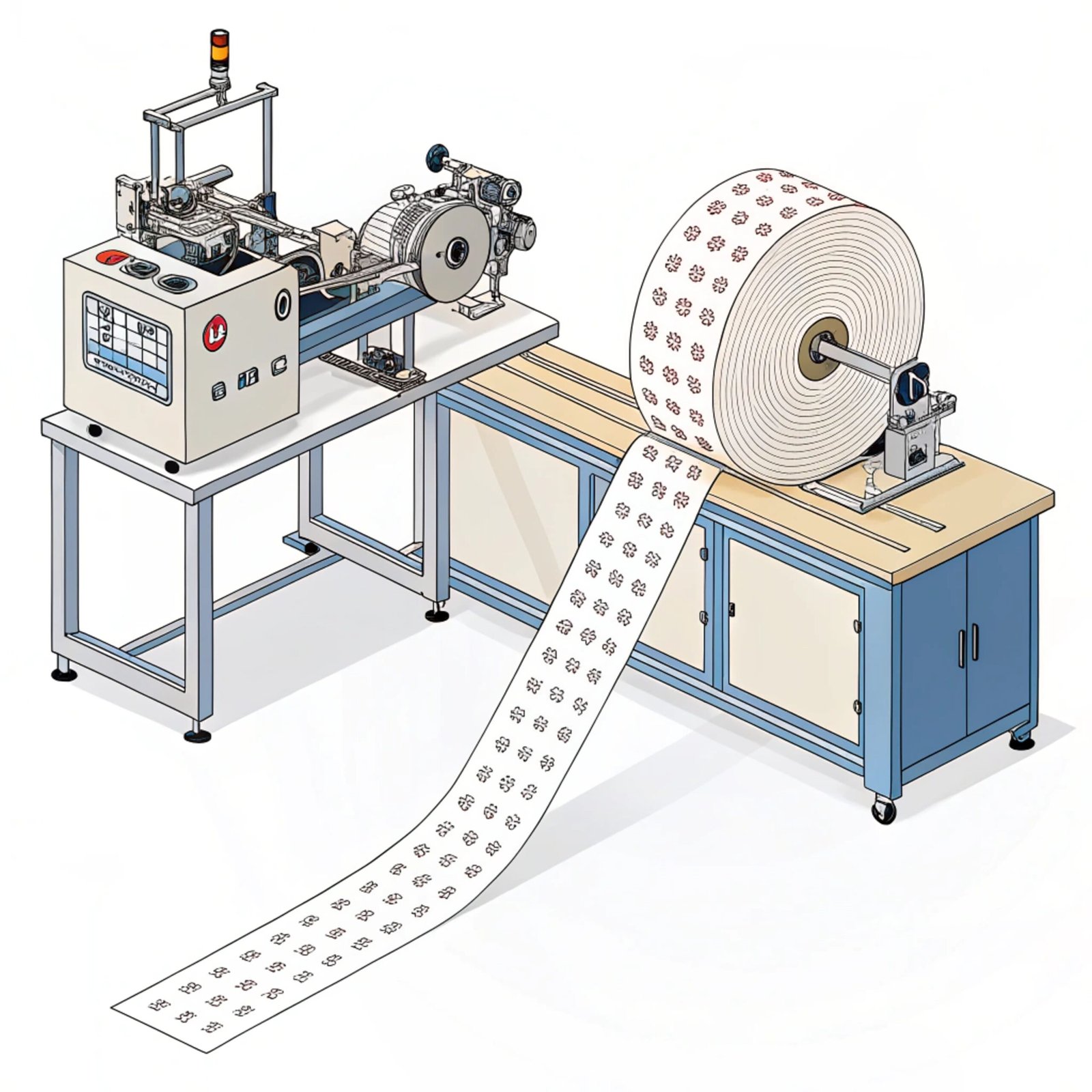

How does our punching machine work for label production?

Manual cutting can’t deliver clean punches or maintain batch consistency. And basic die presses struggle with adhesive layers.

Our adhesive Velcro punching machine uses hydraulic or pneumatic power to punch precise shapes — even on sticky-backed, thick materials.

Machine Workflow

- Feed Velcro Roll or Sheet: Manual or auto-feeding options

- Align Material: Sensors detect edges and adjust positioning

- Punch with Custom Die: Clean, burr-free edges every time

- Separate Waste: Matrix removal system ensures clean cut-outs

- Collect Finished Labels: Labels stack or roll automatically

The punch mechanism is specially designed to avoid glue build-up and edge fraying — ideal for sensitive adhesives and medical-grade Velcro.

What types of labels can it create?

You’re not limited to squares. Many brands need circles, ovals, logos, or notched edges.

Our machine supports a wide range of label shapes and sizes, using interchangeable steel rule dies or rotary dies for high-speed punching.

Common Label Shapes

| Shape | Application |

|---|---|

| Circle | Hook and loop dots for modular boards |

| Rounded Rectangle | Name badges, retail tags |

| Square | Patch backings, industrial tags |

| Custom Logo | Branded hook and loop attachments |

Supported Sizes

| Dimension Range | Examples |

|---|---|

| 10mm – 150mm | Cable tags, uniform patches |

| Up to 300mm width | Oversized shelf labels |

| Multi-hole patterns | Medical device patches |

We also offer custom die development, so if you’re producing a branded Velcro label, we’ll match your shape perfectly.

What are the benefits for label manufacturers?

Whether you make labels for uniforms, tools, or packaging, speed and consistency are essential to stay profitable.

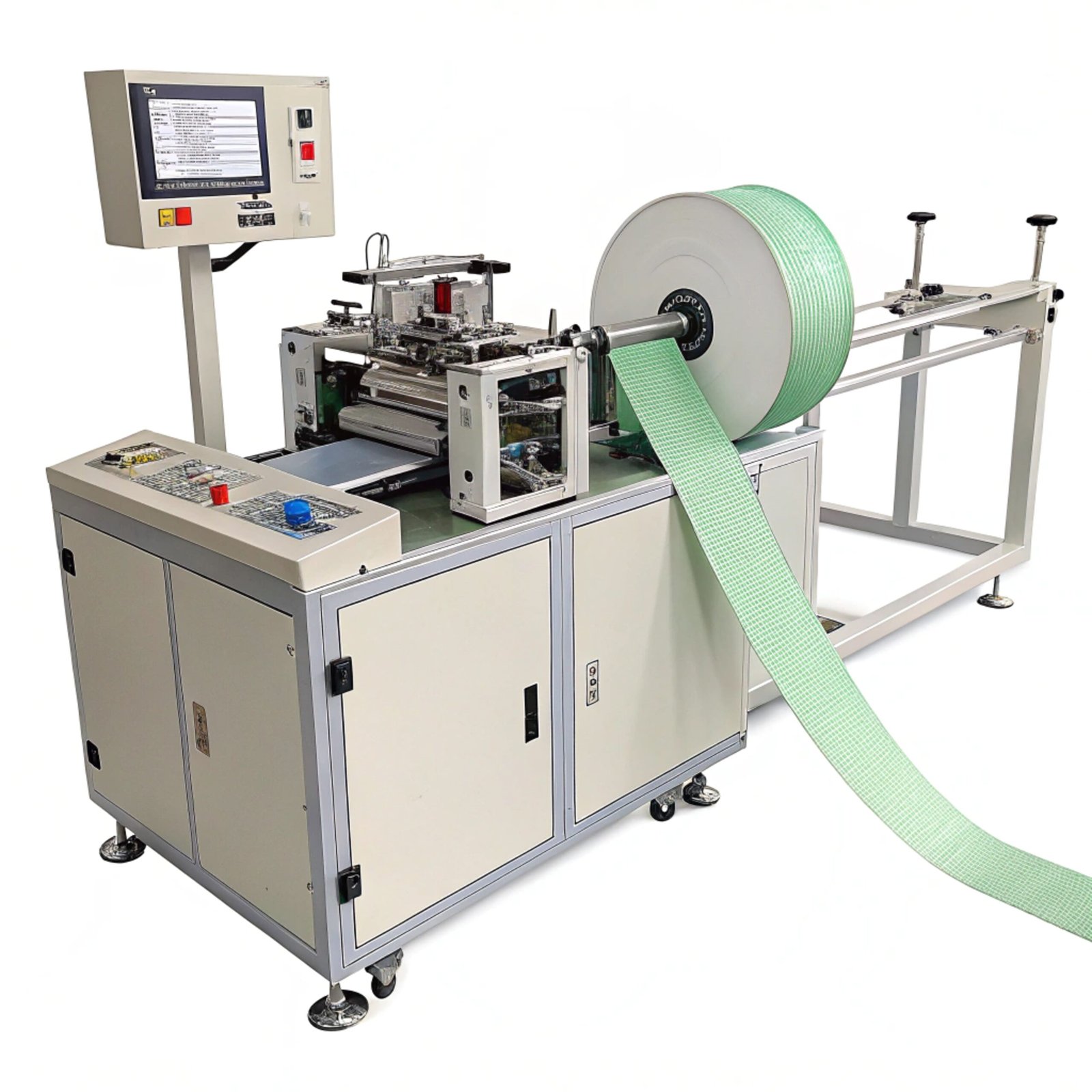

Our punching machine increases your output, reduces human error, and lowers material waste — all with a compact, operator-friendly design.

Key Benefits

- High Output: 3,000–6,000 labels/hour

- Clean Punch: No fraying, melting, or glue distortion

- Minimal Waste: Optimized die layout reduces offcuts

- Operator-Friendly: Easy to switch dies and adjust pressure

- Compact Footprint: Tabletop and stand-alone models available

Case Example: Tactical Gear Label Manufacturer

- Previous method: Manual die press (400–600 pcs/hour)

- Upgraded to Haoxinhe Velcro punching machine:

- Output jumped to 4,800 pcs/hour

- Reduced defect rate by 90%

- Setup time dropped from 25 minutes to 3 minutes

Even small changes in efficiency multiply fast — especially when you’re supplying bulk orders or government contracts.

What adhesive and Velcro types are supported?

Not all Velcro labels are the same — some use heavy-duty adhesives, others need flame retardant or latex-free materials.

Our punching machine is built to handle various grades of hook and loop tape, including adhesive-backed materials and special-purpose Velcro.

Supported Materials

| Material | Supported | Notes |

|---|---|---|

| Nylon Hook & Loop | ✅ | Common for durable labels |

| Polyester Velcro | ✅ | Lightweight, low fuzz |

| Adhesive-Backed | ✅ | Cold punch prevents glue distortion |

| Flame Retardant | ✅ | For uniforms and PPE labels |

| Eco Velcro | ✅ | Supported with custom pressure settings |

If your label requires multi-layer punching — such as Velcro + foam backing — we can provide custom die setups and pressure tuning options.

Why choose Suzhou Haoxinhe for Velcro punching machines?

Our machines don’t just work — they work better, longer, and smarter. And we support you from design to delivery.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. is a direct manufacturer with 5 production lines, CE/ISO-certified systems, and worldwide shipping.

What We Provide

Customized Die Punching Machines

Tailored to your Velcro label specsGlobal Logistics

7–15 day shipping worldwideMultilingual Support

English, French, and Chinese teamsTraining & Maintenance

Setup videos, spare parts, and live supportFull Product Ecosystem

Including:- Velcro dot cutting machines

- Webbing ribbon cutters

- Hot and cold cutting machines

- Protective foam and edge banding cutters

We serve clients in Europe, North America, Southeast Asia, and Australia, with trusted experience in both general and specialized cutting.

Conclusion

If you produce hook and loop labels at scale, our adhesive Velcro punching machine helps you cut cleaner, faster, and with absolute consistency — so you can focus on growing your label business.

Insights

For label manufacturers using adhesive Velcro, Suzhou Haoxinhe’s punching machine delivers precision cutting, high output, and consistent shape control. It handles complex materials like sticky-backed Velcro, supports custom die shapes, and reduces labor and waste. Ideal for uniform, electronics, and packaging labels — it’s the smart upgrade for scalable label production.