Improving Efficiency with Custom-Size Bubble Wrap Cutting Solutions?

Standard wrap sizes don’t always fit your product — and manual adjustments cost time and money.

Custom-size bubble wrap cutting machines help factories package faster, protect better, and reduce waste by tailoring every cut to the product’s exact dimensions.

Let’s explore how custom-cutting solutions improve packaging efficiency across various industries.

Why custom-sized bubble wrap matters?

Using oversized or undersized bubble wrap leads to inefficient protection and excessive material use.

Cutting wrap to custom lengths ensures a perfect fit for each item, reducing over-wrapping and speeding up the packing process.

Issues with Standard Rolls

- Excess wrap increases material costs

- Short sheets leave edges exposed

- Manual trimming slows down workflow

- Inconsistent cuts affect product presentation

- Leads to bulky packaging and higher shipping costs

Custom-cutting removes the guesswork — and transforms packaging from reactive to precise.

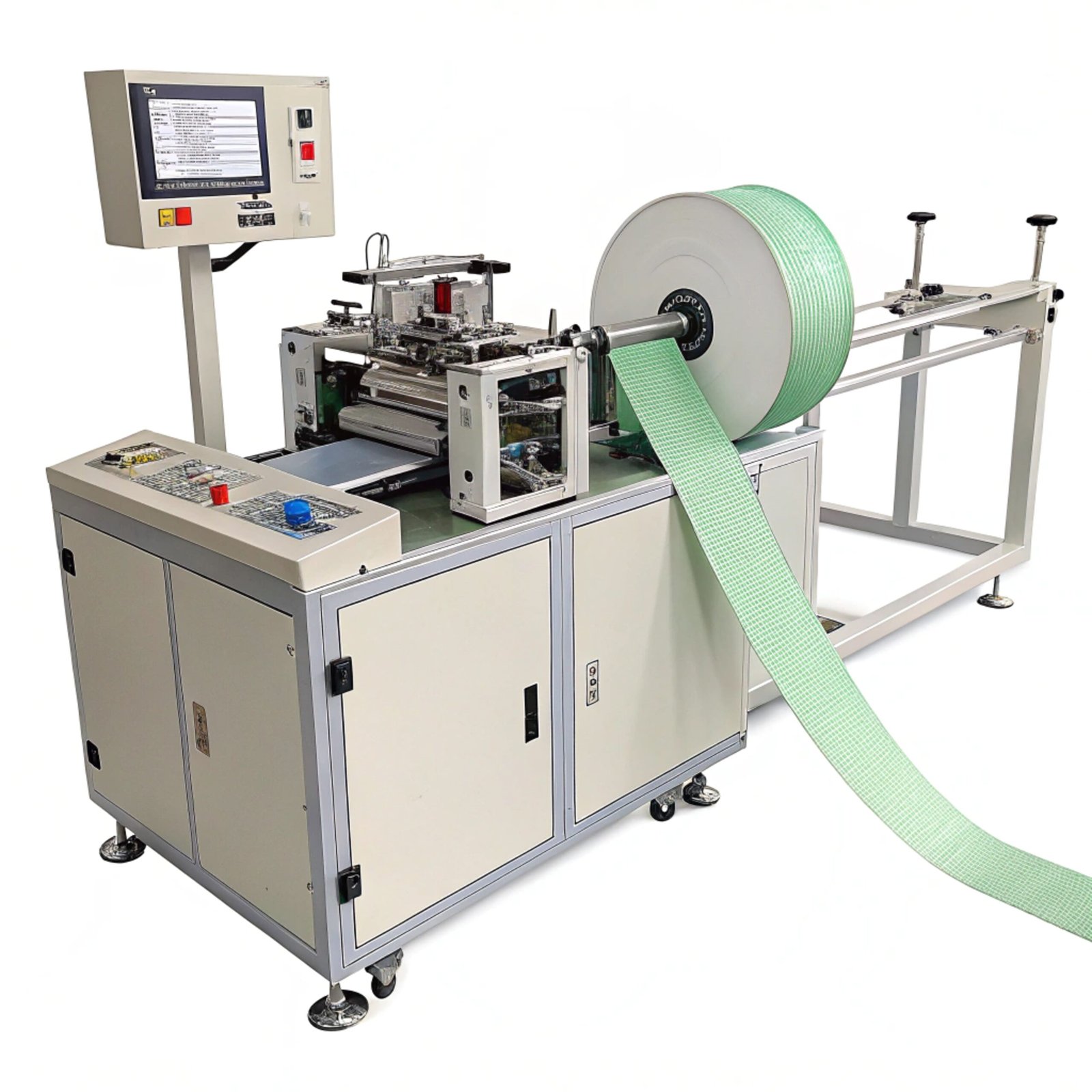

How do custom-size bubble wrap cutting machines work?

Unlike pre-sized rolls or hand-measured sheets, a cutting machine automatically delivers perfectly sized wrap, every time.

Operators input the exact length needed, and the machine feeds, cuts, and dispenses the sheet — on demand or in batches.

Core Features

- Touchscreen programmable interface

- Length range: 200mm–3000mm+

- Width range: 300mm–1500mm

- Cold-cut or hot-cut blade options

- Speed adjustment and repeat counters

This allows fast changeovers between different product sizes, with minimal downtime or training.

Where do custom-cutting solutions save the most time?

Every second counts on a production floor — and packing delays are common when wrap isn’t sized right.

Custom-size cutters eliminate the need to measure, mark, trim, or re-wrap — giving your team pre-sized sheets, ready to go.

Applications by Industry

| Industry | Custom Cut Use |

|---|---|

| Electronics | Device wraps, tray liners, anti-static films |

| Furniture | Edge protection, shelf wraps, seat panels |

| Appliances | Glossy surface wraps, side protection |

| Logistics | SKU-based wrap prep for order fulfillment |

| Glassware | Box liners, separators, and corner wraps |

In each case, consistent wrap sizes lead to faster packing, fewer errors, and cleaner product presentation.

What are the main benefits of custom-size cutting?

Beyond speed, custom cutting improves accuracy, reduces material costs, and supports lean manufacturing.

Key Benefits

- Less Material Waste: Exact-fit sheets reduce overcutting

- Faster Wrapping: No trimming or guesswork

- Cleaner Lines: Professional, uniform packaging

- Lower Shipping Costs: Compact wrapping = smaller cartons

- Repeatable Results: Great for QA and customer experience

Some factories report 20–40% savings in wrap usage after switching to custom-cutting workflows.

What features should you look for?

Not all bubble wrap machines offer true customization — choose one that gives flexibility and control.

Must-Have Features for Custom-Size Cutting

| Feature | Why It Matters |

|---|---|

| Programmable Length Control | Set and save multiple wrap sizes |

| Variable Speed Settings | Match output to packing pace |

| Memory Presets | Store dimensions for repeat jobs |

| Cut Accuracy | ±1mm for minimal variation |

| Width Customization | Works with wide and narrow rolls |

| Cold or Hot Blade Option | Protects bubbles or seals edges as needed |

Suzhou Haoxinhe’s bubble wrap cutting machines meet all these criteria — built for factories that value speed and precision.

Can it handle multiple product sizes?

Most factories handle multiple SKUs — and changing wrap sizes manually slows everything down.

Our machines let you save custom presets for each SKU or category, so operators switch wrap lengths in seconds.

Example SKU Presets

| Product | Cut Length |

|---|---|

| Tablet Screen | 300mm |

| Laptop Chassis | 600mm |

| Microwave Panel | 1000mm |

| Flatpack Cabinet | 1500mm |

| LED Display Panel | 2000mm |

Switching from one to the next is as simple as tapping a new program on the control panel.

Why choose Suzhou Haoxinhe for custom solutions?

We understand that every product is different — and packaging should match.

Suzhou Haoxinhe Electrical Equipment Co., Ltd. builds cutting machines for real factories, with support for custom sizing, high-speed output, and worldwide delivery.

What You Get With Us

- CE/ISO-certified equipment

- Custom width and blade options

- Cold, hot, and perforation modes

- Touchscreen control with 10+ memory presets

- Global delivery (7–15 days)

- Multilingual setup support (EN/FR/CN)

- Remote training and troubleshooting

We also produce:

- Velcro dot and label cutters

- Foam sheet and edge banding cutters

- Webbing ribbon cutting machines

- Roll-to-roll and roll-to-sheet systems

We help electronics brands, furniture factories, 3PLs, and appliance makers streamline their wrap process and save on every roll.

Conclusion

Custom-size bubble wrap cutting solutions give your factory speed, control, and consistent protection — cutting costs while improving packaging quality.

Insights

Custom-size bubble wrap cutting machines from Suzhou Haoxinhe let factories program exact sheet lengths for faster, cleaner, and more efficient packaging. With touchscreen controls, memory presets, and high-speed output, these machines boost productivity and reduce waste across industries.