How to Punch Holes in Nylon Webbing Without Damaging It?

When I first tried punching holes in nylon webbing, I ended up with melted edges and fraying strands. That mistake cost me time, money—and my temper.

To punch clean, damage-free holes in nylon webbing, you need the right tools, controlled heat, and proper support underneath the material.

Getting it right means saving materials, maintaining product strength, and meeting production schedules. In this guide, I’ll break down how I’ve perfected this process in my factory, and how you can apply the same technique to your production line.

What Tools Do You Need to Punch Nylon Webbing Without Damage?

I used to think any standard punch would work. But nylon is sensitive—it melts, it frays, and it can warp. The secret lies in choosing the right combination of precision and temperature.

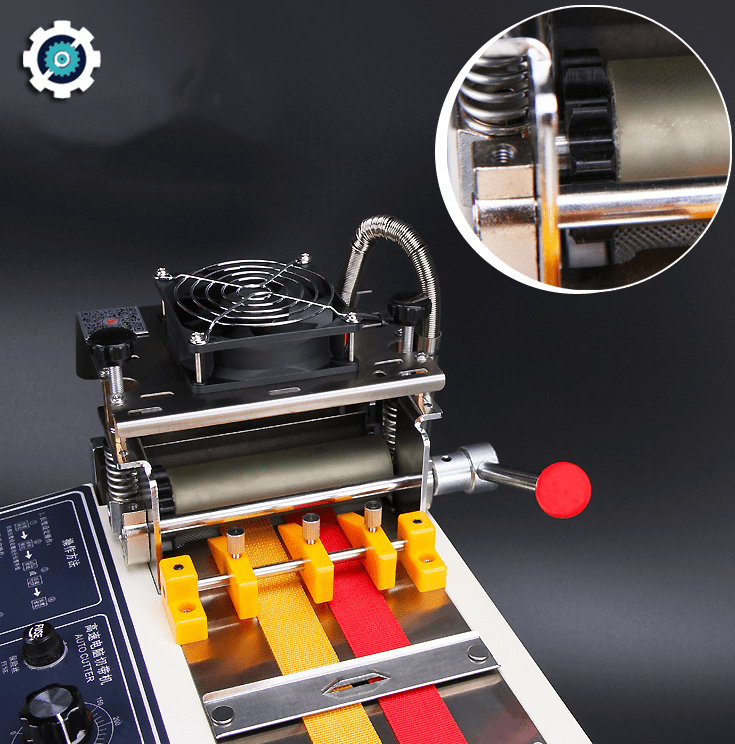

Use a heated hole punch1, a strong cutting base, and a pressing jig to punch nylon webbing cleanly and consistently.

Why a Heated Punch Works Better

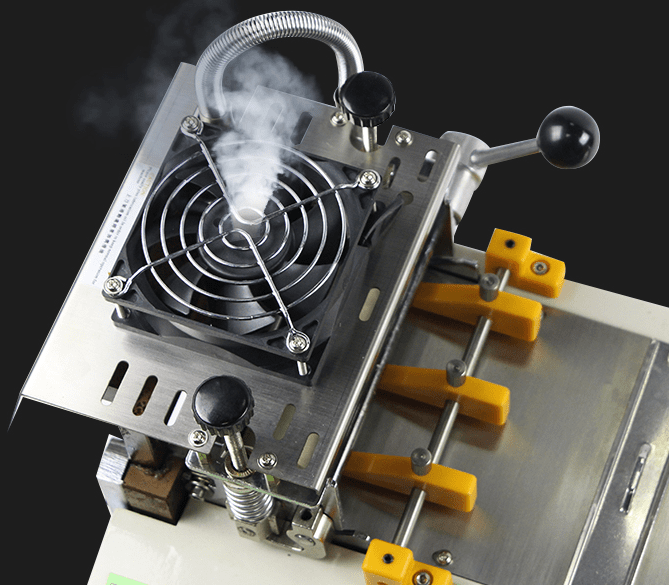

A heated punch melts the edges slightly as it cuts, sealing the webbing. This prevents fraying. Unlike scissors or cold dies, it also keeps the edges smooth.

Essential Tools Table

| Tool | Why It’s Needed |

|---|---|

| Heated Hole Punch | Seals fibers while cutting |

| Metal Cutting Base | Provides firm backing to avoid jagged holes |

| Teflon Jig or Fixture | Ensures repeatable alignment and spacing |

| Clamp or Press | Applies uniform pressure |

| Suction or Ventilation Unit | Removes fumes generated during punching |

I’ve used both manual and pneumatic punches depending on order size. For mass production, my go-to is the automatic punching cutting machine2 from Suzhou Haoxinhe Electrical Equipment Co., Ltd. It’s fast, precise, and customizable.

How Can You Prevent Fraying After Punching?

Even with a clean hole, nylon webbing can unravel. I’ve seen clients patch up frayed holes with glue and lighters—both risky.

Prevent fraying by using heat to seal edges, and choose high-density webbing for better structural integrity.

Steps to Reinforce the Hole

- Use a hot punch – as explained earlier, it seals while cutting.

- Apply edge sealer – a nylon-compatible liquid that strengthens the area.

- Back it with a washer or grommet – this adds durability for tension points.

- Test for load-bearing – especially if used in harnesses or outdoor gear.

I’ve noticed that customers who skip sealing often return with complaints. Once I added the sealing process to my automatic machines, returns dropped by over 30%.

Best-Selling Machines for Fray-Free Finishing

Suzhou Haoxinhe offers several solutions:

- Webbing ribbon cutting machine – includes heated blades.

- Hot and cold cutting machine – versatile and precise.

- Round shape cutting machine – great for soft hole finishes.

If you handle multiple materials like bubble wrap or PVC edge banding, the Protective Foam Cutting Machine or PVC Edge Banding Cutting Machine also help keep finishes clean.

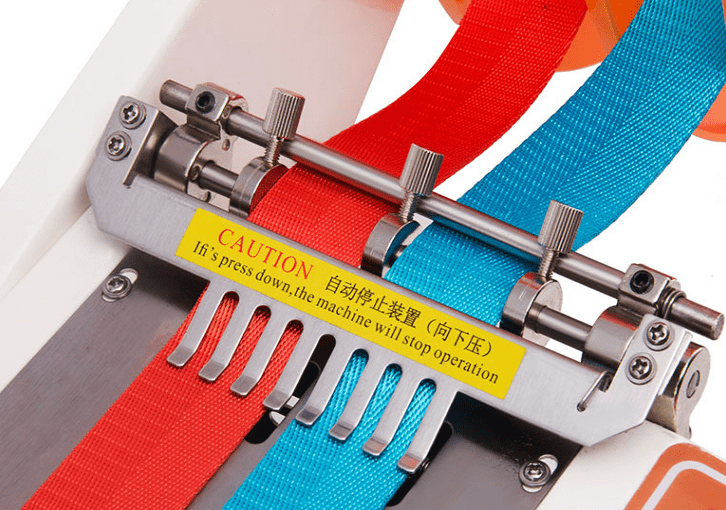

What’s the Safest Way to Align Multiple Holes on Webbing?

A misaligned hole can ruin the final product, especially for load-bearing applications. This is where precision and repeatability become critical.

The safest way is to use a punching jig or CNC-controlled punching machine to ensure consistent spacing and alignment.

My Factory Process for Multi-Hole Webbing

In our workshop, we use the automatic punching cutting machine2 from Suzhou Haoxinhe. Here’s how we align:

- Pre-program spacing and hole diameter via the machine interface.

- Use a Teflon jig that aligns the webbing before each punch.

- Laser guides for operators to double-check placement.

- Batch inspection every 50 units to ensure quality control.

If you’re doing this manually, mark the webbing with a heat-safe fabric pen and clamp it before punching. But for large orders, go automatic.

Alignment Techniques: Manual vs. Automated

| Method | Accuracy | Speed | Best For |

|---|---|---|---|

| Manual Jig | Medium | Low | Small batch or prototyping |

| CNC Punching | High | Fast | Large-scale production |

| Laser Marking | High | Medium | Lightweight webbing with tight specs |

We supply machines to many factories in the chemical, printing, and pharmaceutical industries where alignment isn’t optional—it’s critical.

Conclusion

Use the right tools and sealing techniques to punch holes in nylon webbing without damage.

Insights

To punch holes in nylon webbing without damaging it, use a heated hole punch1, ensure clean alignment with a jig or CNC machine, and seal edges to avoid fraying. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers cutting and punching machines that improve consistency and prevent waste.