How to prevent a cut edge of knitwear from fraying?

Knitwear is soft, flexible, and comfortable, but cutting it without fraying can be a challenge. Unlike woven fabrics, knits are made of interlooped threads, which easily unravel when cut. If not handled properly, a clean-cut edge can quickly turn into a mess of loose threads.

The best way to prevent a cut edge of knitwear from fraying is to use a cutting machine with a heat-sealing function1, apply fabric glue, or use a specialized fray-preventing solution. These methods reinforce the edge, preventing unraveling while maintaining fabric flexibility.

Understanding the best cutting and sealing techniques will help keep your knitwear edges smooth and durable. Let’s explore the most effective ways to seal fabric edges without sewing.

How to Seal Fabric Edges Without Sewing but by Cutting Machine?

Sewing is a common way to reinforce fabric edges, but what if you want to prevent fraying without sewing? Cutting machines provide a precise, clean cut and, when combined with heat or special coatings, can effectively seal fabric edges.

To seal fabric edges without sewing, use a hot knife2, laser cutter, or ultrasonic cutting machine3. These machines cut and seal the edges simultaneously, preventing fraying and unraveling.

1. Hot Knife Cutting – Best for Synthetic Knit Fabrics

A hot knife is one of the most effective tools for cutting and sealing synthetic knitwear, such as polyester blends. It works by melting the edges as it cuts, creating a smooth, sealed finish.

How to Use a Hot Knife:

- Plug in the hot knife2 and let it heat up.

- Place the fabric on a heat-resistant surface.

- Slowly guide the hot knife2 through the fabric, applying gentle pressure.

- Let the edges cool before handling.

🔥 Best for: Synthetic knit fabrics (polyester, nylon).

⚠ Tip: Work in a well-ventilated area to avoid inhaling fumes.

2. Laser Cutting – Best for High-Precision Projects

A laser cutter is ideal for cutting delicate knitwear with high precision. It burns the edges as it cuts, preventing fraying. This method is commonly used in the fashion and textile industries for intricate patterns and fine details.

How Laser Cutting Works:

- The laser follows a digital pattern, cutting the fabric with intense heat.

- The heat slightly melts the edges, sealing them to prevent fraying.

- This method is highly precise and works well for complex designs.

🔍 Best for: Thin, delicate knit fabrics with intricate patterns.

⚠ Tip: Adjust laser intensity to avoid scorching the fabric.

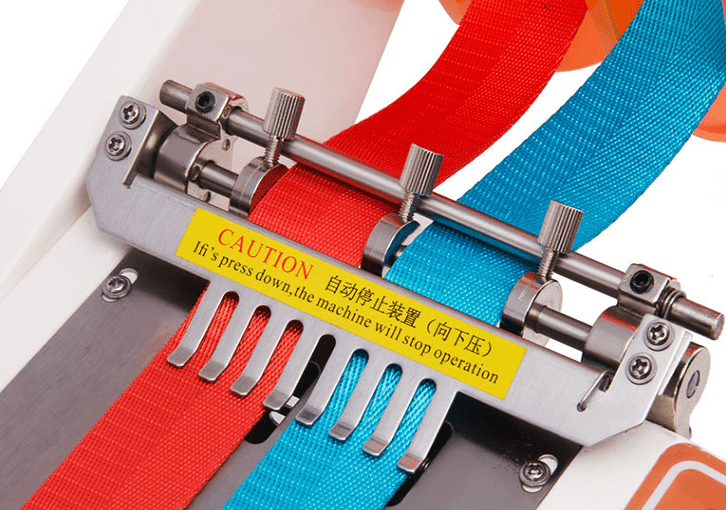

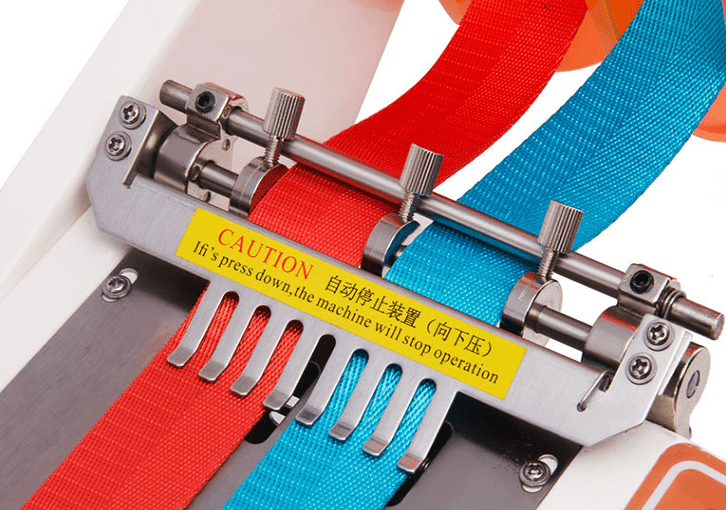

3. Ultrasonic Cutting – Best for Soft and Delicate Knitwear

An ultrasonic cutting machine3 uses high-frequency vibrations to cut and seal knitwear simultaneously. This method is used in professional garment production for seamless and clean fabric edges.

Benefits of Ultrasonic Cutting:

✔ No heat damage – prevents fabric from hardening.

✔ Smooth, flexible finish – maintains knitwear softness.

✔ Works on both natural and synthetic fabrics.

💡 Best for: Luxury knitwear, silk blends, and sportswear fabrics.

4. Rotary Cutter with Fray-Resistant Blades

For small projects, a rotary cutter with a pinking or fray-resistant blade can help reduce fraying. While it doesn’t seal the edges, it makes the unraveling process much slower.

How to Use a Rotary Cutter:

- Place the fabric on a cutting mat.

- Use a pinking or wavy-edge rotary blade to cut the knitwear.

- Apply fabric glue or fray check for extra protection.

✂ Best for: Cotton knits and lightweight fabrics.

⚠ Tip: This method works best for temporary fray prevention.

Comparison of Cutting Machines for Sealing Fabric Edges

| Cutting Machine | Best For | Advantages | Disadvantages |

|---|---|---|---|

| Hot Knife | Synthetic knit fabrics | Cuts and seals in one step | Produces fumes, not suitable for natural fabrics |

| Laser Cutter | Intricate patterns and fine knits | High precision, no physical contact | Requires specialized equipment |

| Ultrasonic Cutter | Soft and delicate knits | No heat damage, smooth finish | Expensive, mainly used in factories |

| Rotary Cutter (Pinking Blade) | Cotton knits, casual wear | Simple, affordable | Does not fully prevent fraying |

Additional Ways to Prevent Fraying After Cutting

Even with a cutting machine, some fabrics may need extra reinforcement. Here are additional ways to keep knitwear from fraying:

1. Applying Fray Check or Fabric Glue

- Dab a small amount along the cut edge.

- Let it dry completely before handling.

- Best for delicate knit fabrics like wool blends.

2. Using Heat-Activated Hem Tape

- Place the tape along the cut edge.

- Use an iron to activate the adhesive.

- Works well for temporary fixes.

3. Coating Edges with Clear Nail Polish

- Apply a thin layer to the cut edge.

- Let it dry for a flexible seal.

- Best for small DIY projects.

Conclusion

To prevent a cut edge of knitwear from fraying, the best approach is to use a hot knife, laser cutter, or ultrasonic cutting machine for a precise, sealed edge. Additional methods, such as fabric glue and fray check, offer extra protection for delicate fabrics.

Insights

- For synthetic knits, a hot knife is the best option as it cuts and seals at the same time.

- Laser cutting is ideal for intricate designs but requires special equipment.

- Ultrasonic cutting is the most advanced method for seamless, professional results.

- For home projects, fabric glue or pinking shears can help minimize fraying.

By choosing the right cutting and sealing method, you can achieve clean, fray-free edges on any type of knitwear.

Explore this link to understand how heat-sealing cutting machines work and their benefits for preventing fraying in knitwear. ↩

Learn about the effectiveness of hot knives in cutting and sealing knitwear edges, ensuring a professional finish. ↩ ↩ ↩

Discover the advantages of ultrasonic cutting machines for achieving seamless edges in knitwear without heat damage. ↩ ↩