How to minimize downtime on bubble wrap cutting machines?

When your bubble wrap cutting machine suddenly stops mid-shift, every minute costs money. Downtime kills efficiency, delays orders, and frustrates your production team.

To minimize downtime, you need to switch from reactive to predictive maintenance. That means using real-time counters and I/O sensors to detect issues before they cause shutdowns.

If you’re only reacting after a machine breaks, you’re already too late.

Adding counters/IO sensors for predictive maintenance and alert thresholds?

Even a high-speed machine won’t help if it constantly goes down for unplanned maintenance.

Integrating I/O sensors, usage counters, and digital alerts helps predict wear and tear, allowing scheduled servicing before failure. It’s the backbone of modern lean production.

Let’s explore how this works — and what it looks like inside a bubble wrap cutting machine.

What causes downtime in bubble wrap cutting machines?

Before solving downtime, you have to understand where it comes from. At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we service hundreds of machines yearly, and we’ve tracked the top causes of unplanned stops:

Common Downtime Triggers

| Cause | Example Impact |

|---|---|

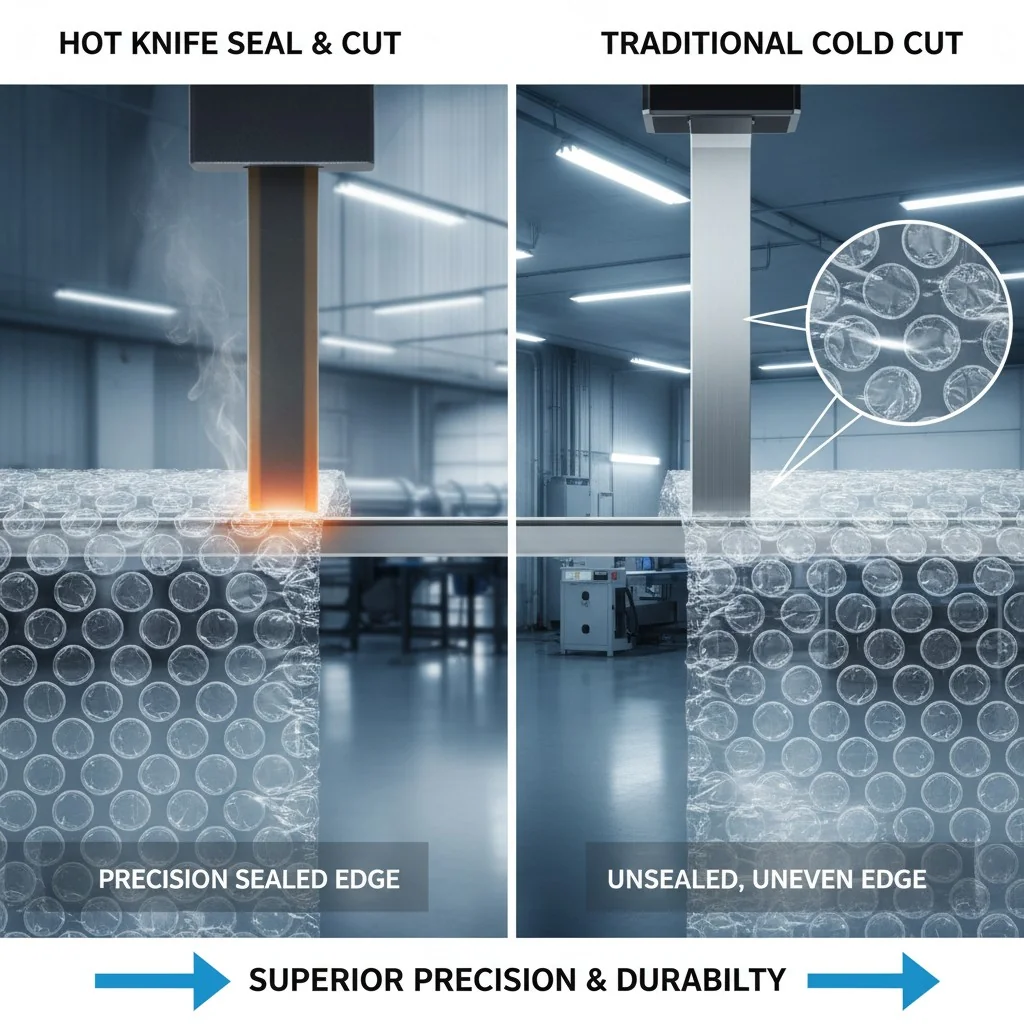

| Knife wear or overheating | Jagged cuts, machine halt |

| Feeding roller slippage | Misalignment, material jam |

| Static buildup | Material sticking or failing to feed |

| Sensor malfunction | Missed cut lengths, false triggers |

| Lack of scheduled maintenance | Sudden motor stop, burnt fuses |

Most of these can be predicted with the right sensor setup.

How counters and sensors prevent unexpected stops

1. Knife usage counters

We embed usage counters that track:

- Number of cuts made

- Time in active operation

- Temperature fluctuations (if using hot knives)

Once thresholds are hit (e.g., 100,000 cuts), the system alerts for blade replacement before degradation impacts quality.

2. Motor load sensors

We measure torque resistance on servo motors to detect abnormal loads (which may mean roller wear or material tension issues). Once resistance exceeds a set threshold, an alert triggers for inspection.

3. I/O sensor mapping

In machines like our webbing ribbon cutting machine or protective foam cutter, input/output sensors track everything from:

- Material presence

- Feeding consistency

- Cutter arm return speed

All this data flows into a small PLC (programmable logic controller) with a touchscreen interface.

We allow clients to set custom error limits. For example:

- If feeding delay exceeds 2 seconds = yellow warning.

- If delay exceeds 5 seconds = machine auto-stop + red alert.

4. Preventive maintenance scheduling module

Machines like our bubble wrap cutting machine include an optional maintenance timer. After a programmable period (e.g., 150 operating hours), the machine will prompt cleaning, lubrication, or inspection.

Here’s what this looks like in real operations:

Real setup: Cutting bubble film in 2-shift factory

A customer in Singapore runs two shifts daily cutting air bubble film. They were losing 1 hour per day on re-alignments and cutter cleaning due to manual oversight.

We added:

- A real-time blade cut counter (auto alert at 50,000 cuts)

- Heat knife temperature sensor with alert if temp drops below 160°C

- Roller feed sensor to check slippage

- Auto stop if three feeding retries fail

Downtime dropped by 78% within 3 weeks, with no extra manpower.

These upgrades cost under $400 USD — and saved more than 10x that amount monthly.

Which machines from Suzhou Haoxinhe offer this?

Our smart sensor integration is available on:

- Automatic punching cutting machine

- Rotary bevel cutting machine

- Hot and cold cutting machine

- Bubble wrap cutting machine

We also offer custom PLC programming for factories with unique KPI or maintenance requirements.

Conclusion

Don’t wait for your bubble wrap cutter to fail. Add smart sensors and set alert thresholds — it’s cheaper than downtime.

Insights

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we understand that uptime equals profits. That’s why we offer sensor-integrated machines like the bubble wrap cutting machine, webbing tape cutting machine, and automatic punching machine, complete with usage counters, motor load sensors, and predictive alert systems — all customizable to your factory workflow.