How to improve cutting accuracy when processing thin-gauge aluminium foil?

Thin-gauge foil tears easily and is hard to control—one miscut and your batch is ruined.

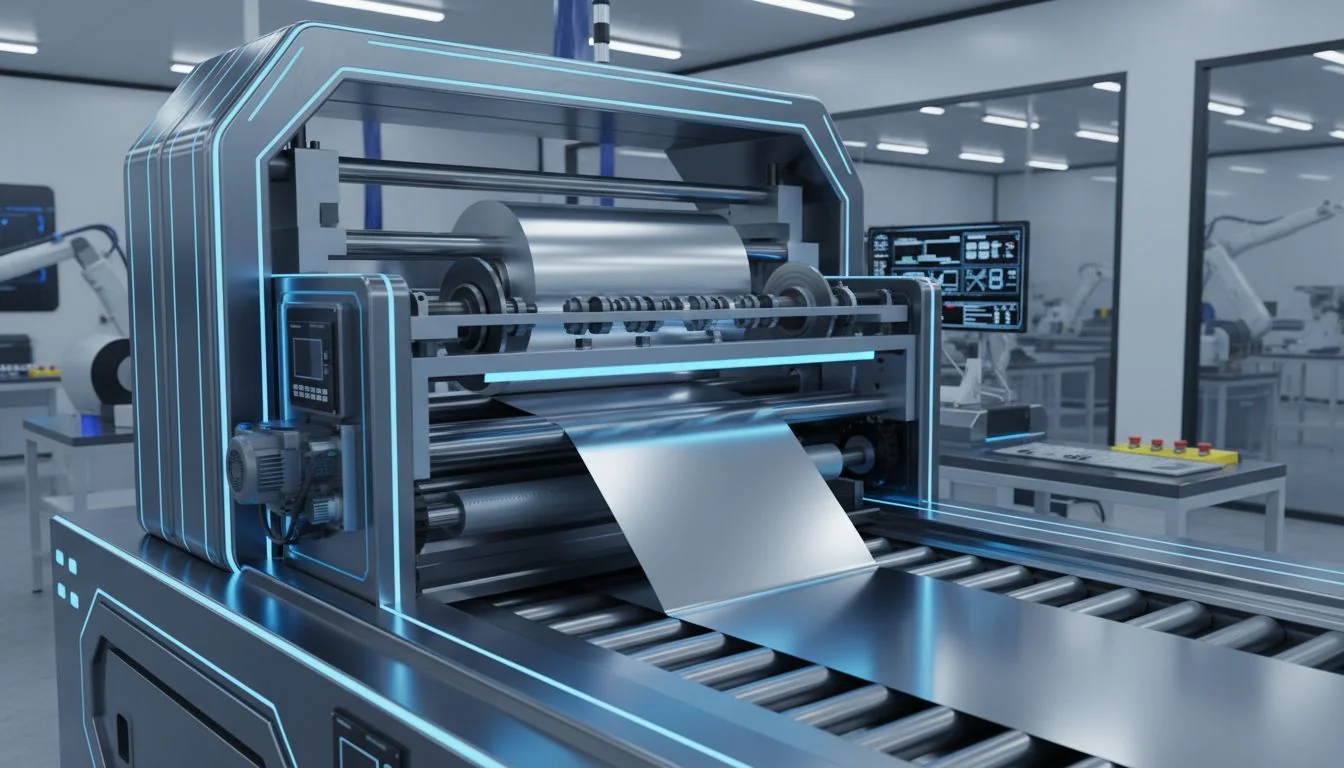

To improve cutting accuracy when processing thin-gauge aluminium foil, use servo motor control, precision blades, tension-adjustable rollers, and anti-static systems to stabilize feed and eliminate tear or misalignment.

When cutting aluminium foil below 20 microns, even air movement or blade friction can cause deviation. Let’s look at how to solve this and maintain consistent output with no rejects.

Which blade materials1 are best suited for precision cutting?

Using the wrong blade leads to jagged edges, foil sticking, or blade overheating.

Tungsten carbide and high-speed steel (HSS) are the most suitable blade materials1 for precision foil cutting. They retain sharpness longer, reduce edge burrs, and withstand high-speed continuous operation.

Let me explain how blade choice directly affects the outcome of every cut, especially in high-precision or high-volume environments.

🔪 Blade Material Comparison Table

| Blade Material | Best For | Sharpness Retention | Cost | Heat Resistance | Suitability for Thin Foil |

|---|---|---|---|---|---|

| Tungsten Carbide | Long runs, ultra-precise cuts | ★★★★★ | High | ★★★★★ | ★★★★★ |

| HSS (High-Speed Steel) | Daily use, mid-range speed | ★★★★☆ | Medium | ★★★★☆ | ★★★★☆ |

| Stainless Steel | Low-budget operations | ★★☆☆☆ | Low | ★★★☆☆ | ★★☆☆☆ |

| Ceramic | Anti-static, low friction | ★★★☆☆ | Medium-High | ★★★★☆ | ★★★★☆ |

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we use industrial-grade tungsten carbide2 and HSS blades across machines like our webbing ribbon cutting machine, automatic punching cutting machine, and hot and cold cutting machine. These are designed for precision and durability when dealing with delicate foil materials.

🔍 Blade Factors That Impact Cutting Accuracy

1. Sharpness Profile

- A micro-serrated edge helps grip foil without tearing.

- Polished blades reduce drag and prevent sticking.

- Sharper blades reduce the pressure required—great for soft foil.

2. Blade Angle

- A lower angle (10°–20°) improves precision but may dull faster.

- Higher angle (25°–30°) increases durability but risks tearing if too aggressive.

- Optimal angle depends on foil thickness and feed speed.

3. Coatings

- TiN or TiCN coatings3 reduce heat buildup and friction.

- These coatings3 help blades stay clean and cut consistently across shifts.

🔁 Maintenance Matters

Even the best blades fail if not maintained. That’s why we recommend:

- Inspect blades every 8–12 production hours

- Use ultrasonic blade cleaning or alcohol wipes

- Replace blades before visible dulling, not after

Our rotary bevel cutting machine and protective foam cutting machine include quick-swap blade mounts, reducing downtime and ensuring consistency.

Techniques to Improve Cutting Accuracy

Let’s go beyond blades—true cutting accuracy4 requires a system-wide approach.

1. Use Servo Motor Drives

Servo systems provide tight control over length, feed speed, and blade movement.

- Accuracy: ±0.1mm or better

- Adjusts in real time based on foil tension

- Ideal for packaging, pharmaceutical, and electronics-grade foil

2. Integrate Tension-Control Rollers

Foil must be flat and taut before cutting.

- Use adjustable pneumatic rollers

- Install dancer arms to balance feed rate with cutter speed

- Prevents wrinkling and shifts

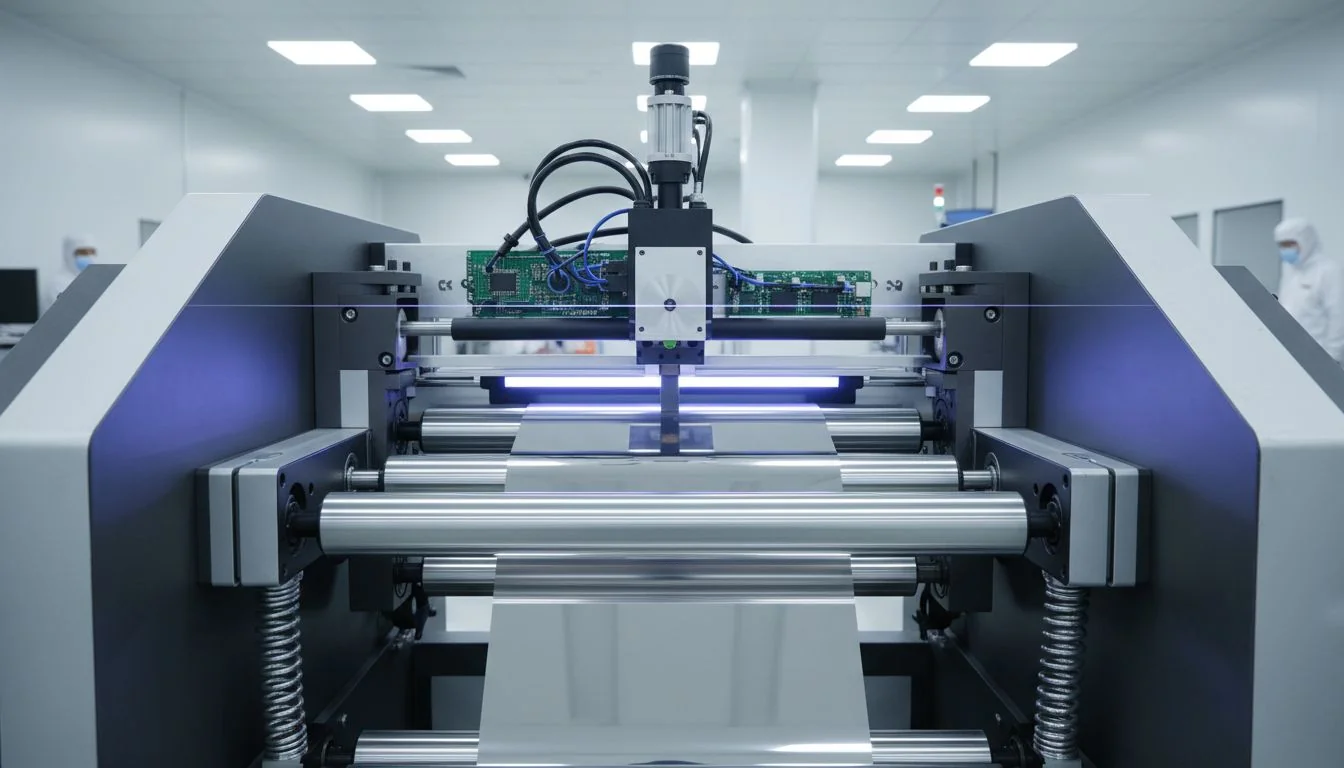

3. Install Anti-Static Devices

Thin foil often attracts dust or folds due to static.

- Use static eliminators5 at feed zone

- Prevent foil sticking to machine parts

- Reduces jam frequency by 40%+

4. Optical Sensors for Edge Tracking

Ensure the foil stays centered.

- Cameras or IR sensors guide positioning

- Ideal for foil rolls with inconsistent winding

Our PVC edge banding cutting machine and bubble wrap cutting machine also benefit from these same technologies, adapted for different materials.

Real-World Gains from Improved Accuracy

One customer in Singapore upgraded their foil cutting line with:

- HSS blades

- Servo motor control

- Static eliminators

Result: 95% cut accuracy, 30% fewer rejects, and faster production changeovers—all within 3 months.

Conclusion

Precision foil cutting starts with the right blade—but only works when supported by stable feed systems and intelligent automation.

🧠 Industry Insights: Cutting Thin-Gauge Foil with Precision in 2026

Over the past decade, I’ve seen countless factories struggle with foil cutting accuracy—especially when working with ultra-thin material under 20μm. What most operators don’t realize is that even microns of misalignment come from system-wide weaknesses, not just dull blades.

Thin foil isn’t forgiving. If your feed tension varies even slightly, or your cutter uses a stepper motor without feedback, the result is jagged edges or foil tearing. That’s why in 2026, high-end converters are investing in servo-synchronized drive systems, anti-static bars, and tungsten-coated blades to maintain repeatability at ±0.1mm. These aren’t luxury features—they’re essential for zero-defect output in industries like pharma blister packaging or battery-grade foil.

At Haoxinhe, the use of quick-change blade mounts, combined with precision-ground carbide tools, allows converters to swap tools mid-shift without recalibration downtime. Pair that with IR-based edge alignment and anti-static discharge zones, and you get a machine that behaves like a surgical instrument, not a brute cutter.

Bottom line: Cutting thin foil accurately requires a synchronized system—not just sharp blades, but smart motors, stable tensioning, and static control built into the design.

Understand the importance of selecting the right blade material for optimal cutting performance. ↩ ↩

Discover why industrial-grade tungsten carbide is preferred for precision cutting applications. ↩

Explore how blade coatings can enhance performance and longevity in cutting applications. ↩ ↩

Explore the various factors that contribute to achieving high cutting accuracy in production. ↩

Understand the function of static eliminators in preventing material sticking and jams. ↩