How to fix length inaccuracy drifting over a shift?

It’s frustrating: your bubble wrap cutter starts the day perfectly calibrated, but by the afternoon, your cuts are 2–3 cm off. This drift causes rework, waste, and customer complaints.

To fix length inaccuracy over long shifts, focus on three areas: encoder calibration, roller wear, and temperature drift in your hot knife system1.

- Length inaccuracy drift during a shift often points to mechanical issues like roller slippage, misalignment, or worn components.

- Start by inspecting rollers, belts, and couplings for signs of wear or improper tension.

- Solutions include adjusting nip pressure, cleaning or replacing damaged parts, and recalibrating the equipment.

- Proper operation and maintenance are essential to prevent environmental factors and gradual wear from impacting accuracy.

- Regular diagnostics ensure consistent cutting precision2 and reduce downtime.

Let’s unpack why your machine’s performance shifts over time—and how to get it stable again.

Calibrating encoder, checking roller diameter wear, temperature drift on hot-knife

Length drift in cutting machines3 often sneaks in slowly. You may notice a few millimeters inaccuracy by hour three, and several centimeters by hour six.

This is usually caused by a mismatch between actual material movement and what your machine “thinks” is happening. The culprits? Miscalibrated encoders, worn rollers, or unstable blade temperature.

Let’s walk through how I troubleshoot and fix each.

🧠 Dive Deeper: Step-by-step diagnosis and solutions

I’ve helped multiple clients resolve this issue, including a customer using our webbing ribbon cutting machine who struggled with 1.5cm drift after every 4 hours of operation. We solved it by checking three key systems.

🔧 Step 1: Encoder Calibration

Most automated cutting machines3—like our hot and cold cutting machines3 or Protective Foam Cutting Machine—use rotary encoders to measure how much material has passed through before triggering the cut.

🔍 Symptoms of encoder drift:

- Cuts get longer or shorter over time

- Drift increases with speed or shift duration

- Machine cuts accurately after reset, then loses precision

✅ Fix:

- Recalibrate encoder using your machine’s control panel. Run a 1000mm test cut and measure the output.

- Adjust the pulse count per mm until your cut matches.

- Check for loose encoder mountings—vibration causes miscounts.

- Clean the encoder disk or shaft—dust and static buildup interfere with signal.

📌 Tip: If using a stepper motor instead of an encoder-based servo, skip to roller checks.

🔧 Step 2: Roller Diameter Wear

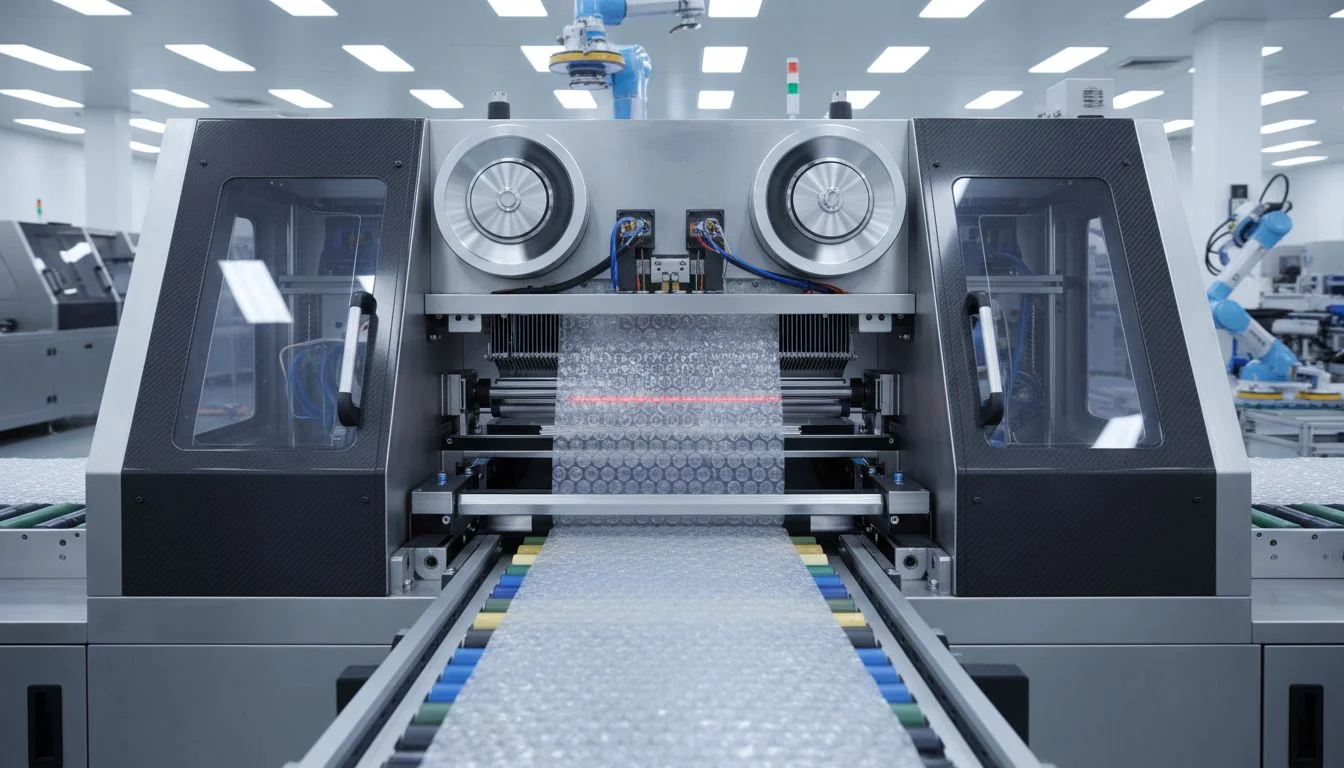

The feeding rollers in machines like our bubble wrap cutting machine wear down over time. Even small changes in diameter alter the material feed rate.

🔍 Signs of roller wear:

- Inaccuracy grows slowly over days/weeks

- Material slipping or minor jamming

- Left-right misalignment on wide rolls

✅ Fix:

- Measure roller diameter at multiple points using calipers

- Compare with original machine specs

- Replace if diameter is reduced by more than 2–3%

- For temporary fixes, adjust cut length offset in software (not ideal for long term)

📌 Tip: Rubber rollers degrade faster in humid, dusty environments. Clean them weekly with alcohol-based cleaner.

🔧 Step 3: Hot-Knife Temperature Drift

Machines like our PVC edge banding cutting machine or rotary bevel cutting machine use hot knives to cut plastic-based materials. Over long shifts, heating elements may fluctuate.

🔍 Signs of temperature drift:

- Cuts take longer over time

- Blade “melts” material more than cuts

- Edge discoloration or sticking

✅ Fix:

- Use a laser thermometer to monitor blade temp every hour

- Replace worn-out thermocouples or sensors

- Make sure the PID control is correctly tuned

- Keep ventilation consistent to avoid sudden cooling

📌 Pro Tip: Install a second temp sensor near the cutting blade—not just on the heater block.

📊 Summary Table: Fixing Drift by Component

| Component | Common Issue | Fix | Frequency |

|---|---|---|---|

| Encoder | Pulse mismatch | Recalibrate, secure mountings, clean | Monthly |

| Feed Roller | Diameter wear/slippage | Replace if 2–3% smaller, clean regularly | Every 3–6 mo |

| Hot Knife System | Temp fluctuations over shift | Add sensor, verify PID control4, clean blade | Weekly |

🛠 HAOXINHE: Built-In Fixes

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we design cutting machines3 like the webbing ribbon cutting machine and hot and cold cutting machine with stability in mind.

Our built-in advantages:

- Dual-encoder feedback systems for real-time correction

- Modular roller design for quick swaps

- Smart PID temperature controllers to keep hot knives consistent hour after hour

If your current machine isn’t holding calibration, we can help customize a solution with higher precision parts and better automation.

Conclusion

To stop cutting length drift, fix encoder mismatch, replace worn rollers, and stabilize hot knife temperature.

Industry Insight: Why Your Cutting Length Drifts Over Time

Cut length drifting mid-shift is one of the most overlooked problems in semi-automated cutting lines. I’ve diagnosed this issue in everything from ribbon cutters in Thailand to protective film machines in Germany. The surprising truth? It’s rarely a mechanical defect—it’s usually a feedback or calibration drift issue.

Here’s what most factories miss: your machine is making decisions based on assumed input, not real-time correction. If your encoder pulses are off by just 1%, a 1000mm cut will become 1010mm by hour six. Combine that with rubber roller compression5 from heat or wear, and you’re now 2–3 cm off. That’s serious waste in industries like electronics packaging or auto interiors.

What I advise? Monthly encoder checks, caliper-based roller wear audits, and hourly hot-knife temperature logs. At HAOXINHE, our machines use dual encoders and PID heat tuning to correct these issues on the fly—especially vital for shift-long cutting stability.

In short: don’t blame the operator or the software too soon. Drifting is a mechanical signal mismatch—fix that, and your precision returns.

Length inaccuracy during long shifts often comes from encoder miscalibration, roller wear, or unstable blade temperature. For reliable performance, choose cutting machines3 like HAOXINHE’s Protective Foam Cutting Machine or Hot and Cold Cutting Machine, which include real-time encoder feedback, replaceable rollers, and PID-controlled heat systems. This ensures consistent cuts—hour after hour—even in high-output B2B settings.

Understanding hot knife systems can enhance your cutting process and material handling. ↩

Improving cutting precision is essential for reducing waste and enhancing product quality. ↩

Stay updated on cutting machine technology to enhance efficiency and precision in your operations. ↩ ↩ ↩ ↩ ↩

Learn about PID control to optimize temperature stability in your cutting processes. ↩

Understanding rubber roller compression can help you maintain consistent material feed rates. ↩