How to Choose the Right Die Size for Your Webbing Punching Machine?

Selecting the wrong die size1 can lead to torn webbing edges, irregular holes, and costly machine damage.

The ideal die size1 depends on your webbing thickness2 and material type – typically 1–2mm larger than your required hole diameter for clean punching and minimal material stress.

1: Select the die size1 based on webbing material type, thickness, and required hole dimensions.

2: Ensure the die opening is slightly larger than the punch diameter to allow proper clearance.

3: Follow the general rule of using a die width around 8 times the webbing thickness2.

4: Adjust the ratio depending on the webbing’s density, flexibility, and composition.

5: Accurate die selection improves punch precision3, prevents material damage, and extends tool life.

Optimizing die size1 ensures efficient, clean cuts and maximizes performance in webbing punching operations.

Let’s examine the optimal hole sizes for different industry applications.

What Hole Sizes Are Best for Military-Grade vs. Fashion Webbing Straps?

Military and fashion applications have completely different functional requirements that dictate their ideal hole dimensions.

Military-grade webbing typically uses 5–6mm holes for durability under load, while fashion straps use smaller 3–4mm holes for aesthetic appeal and material conservation.

Military-Grade Webbing Specifications

Optimal Hole Sizes:

- Combat gear: 6mm ±0.2mm

- Load-bearing equipment: 5.5mm

- Attachment points: 5–6mm reinforced holes

Material Considerations:

| Webbing Type | Recommended Die | Hole Spacing |

|---|---|---|

| Nylon (1000D) | 6mm carbide | 25–30mm |

| Polyester (900D) | 5.5mm steel | 20–25mm |

| Aramid Fiber | 5mm hardened | 30–35mm |

Fashion Webbing Requirements

Key Differences:

- Smaller holes (typically 3–4mm)

- Closer spacing (15–20mm)

- Decorative shapes (stars, slots, ovals)

Popular Fashion Die Sets:

- Handbag straps: 3mm round

- Shoe laces: 4mm round

- Decorative belts: 3.5mm specialty shapes

Die Material Guide:

| Application | Recommended Die | Expected Lifespan |

|---|---|---|

| Military | Tungsten carbide | 500,000 cycles |

| Fashion | Tool steel | 200,000 cycles |

| Sample Room | Standard steel | 50,000 cycles |

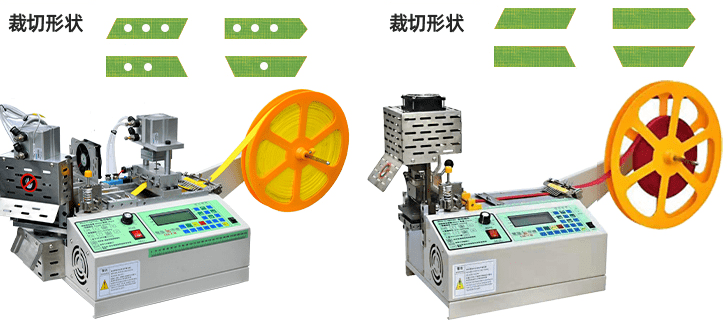

HAOXINHE Machine Settings

Our punching hole webbing cutting machines feature:

✔ Automatic die clearance adjustment

✔ Digital hole spacing control

✔ Quick-change die holders

For best results:

- Clean dies every 10,000 punches

- Lubricate weekly with silicone spray

- Store dies in moisture-proof cases

Conclusion

Always match your die size1 to both material strength and functional requirements — military needs durability, fashion prioritizes appearance.

Insights

From two decades of building webbing punching systems, here’s what separates pros from beginners: they don’t just choose dies for today’s job—they plan for what’s coming next season or contract.

Military clients typically know their specs down to the decimal—5.5mm ±0.2, reinforced dies, tungsten carbide only. Why? Because a frayed edge at the wrong time could mean gear failure under load. That’s why we always recommend carbide for 1000D+ nylon, even if the upfront cost is higher—it pays off in uptime and reliability.

In fashion manufacturing, though, agility is king. A 3mm die one week becomes an oval slot the next. That’s where our quick-change die holders4 have made a huge impact. One luxury brand using our system cut their die swap time from 12 minutes to under 2—and was able to scale from 2 to 6 designs per shift.

So when picking die size1s and formats, don’t just think about diameter. Think about application durability, brand flexibility, and how fast your shop needs to adapt.

Understanding die size is crucial for optimal performance and preventing material damage in webbing operations. ↩ ↩ ↩ ↩ ↩ ↩

Explore how webbing thickness influences die choice to ensure clean cuts and tool longevity. ↩ ↩

Understand the relationship between die selection and punch precision for better manufacturing outcomes. ↩

Explore how quick-change die holders can significantly reduce production time and increase flexibility. ↩